Menthol baking method

A menthol and baking technology, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., to achieve precise control, improve product quality, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

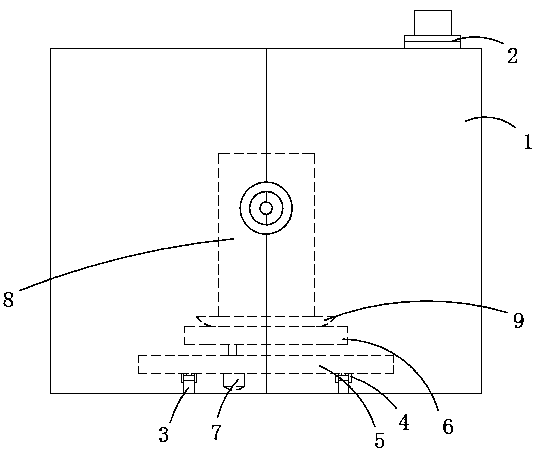

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0016] like Figure 1-Figure 2 Shown, a kind of menthol baking method comprises the following steps:

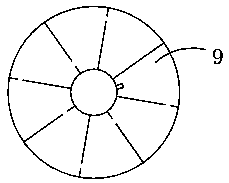

[0017] S1: Open the mouth of the crystallization barrel containing menthol crystals, place the crystallization barrel on the mobile trolley, push the mobile trolley into the drying room 1 along the track, and close the door of the drying room 1. The mobile trolley includes the trolley body 5. Rotate the moving roller 4 arranged under the trolley body 5 and matched with the guide rail 3, rotate the eccentric turntable 6 arranged above the trolley body 5, and drive the eccentric turntable under the trolley body 5 6 rotating drive motor 7, a fixing device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com