Water-borne photodiffusion coating, water-borne photodiffusion film with low light and light loss as well as preparation method and application of water-borne photodiffusion film with low light and light loss

A light-diffusing film and water-based coating technology, applied in the optical field, can solve the problems of inability to achieve high light efficiency and high diffusivity compatibility, and achieve the effects of regular arrangement, uniform coating, and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

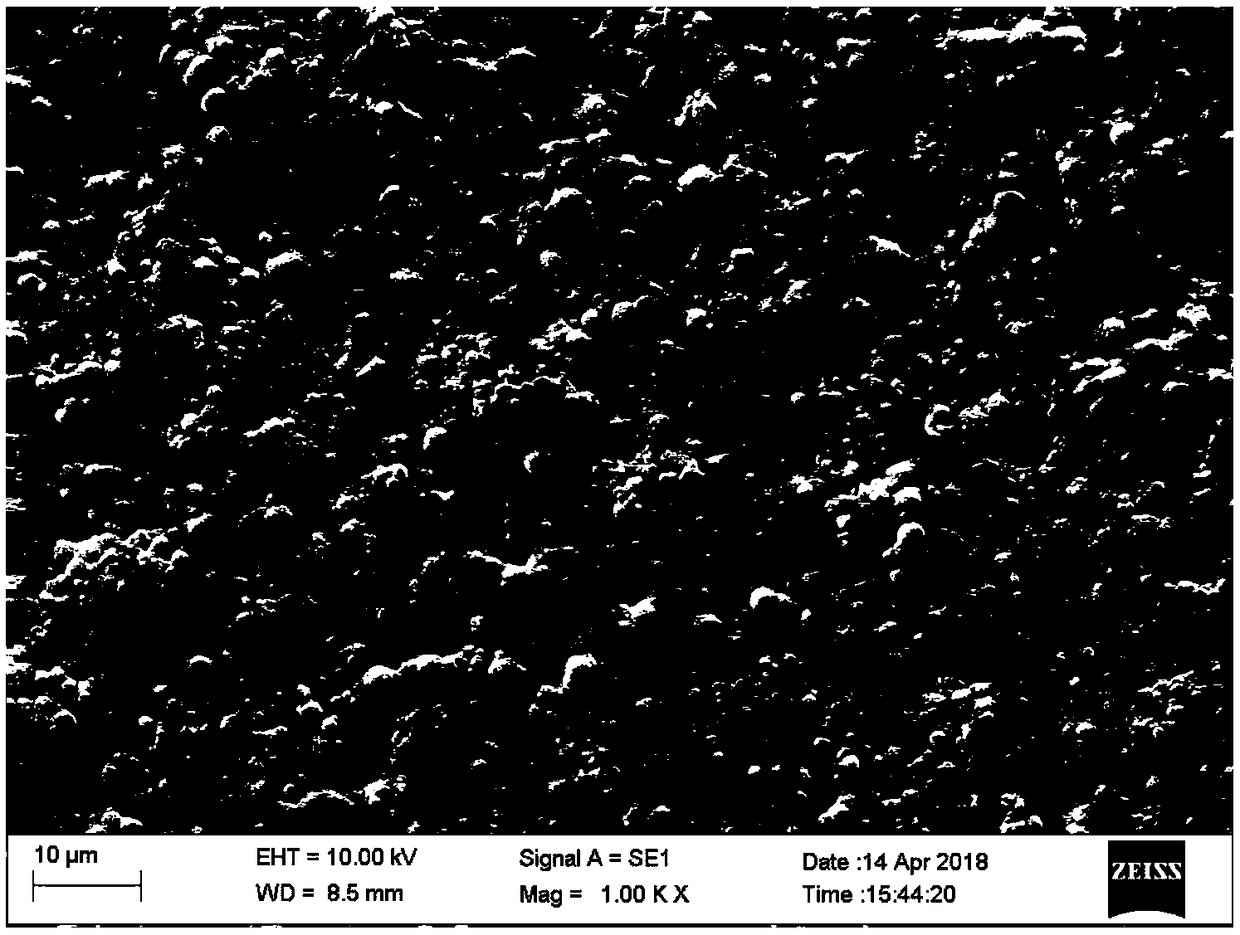

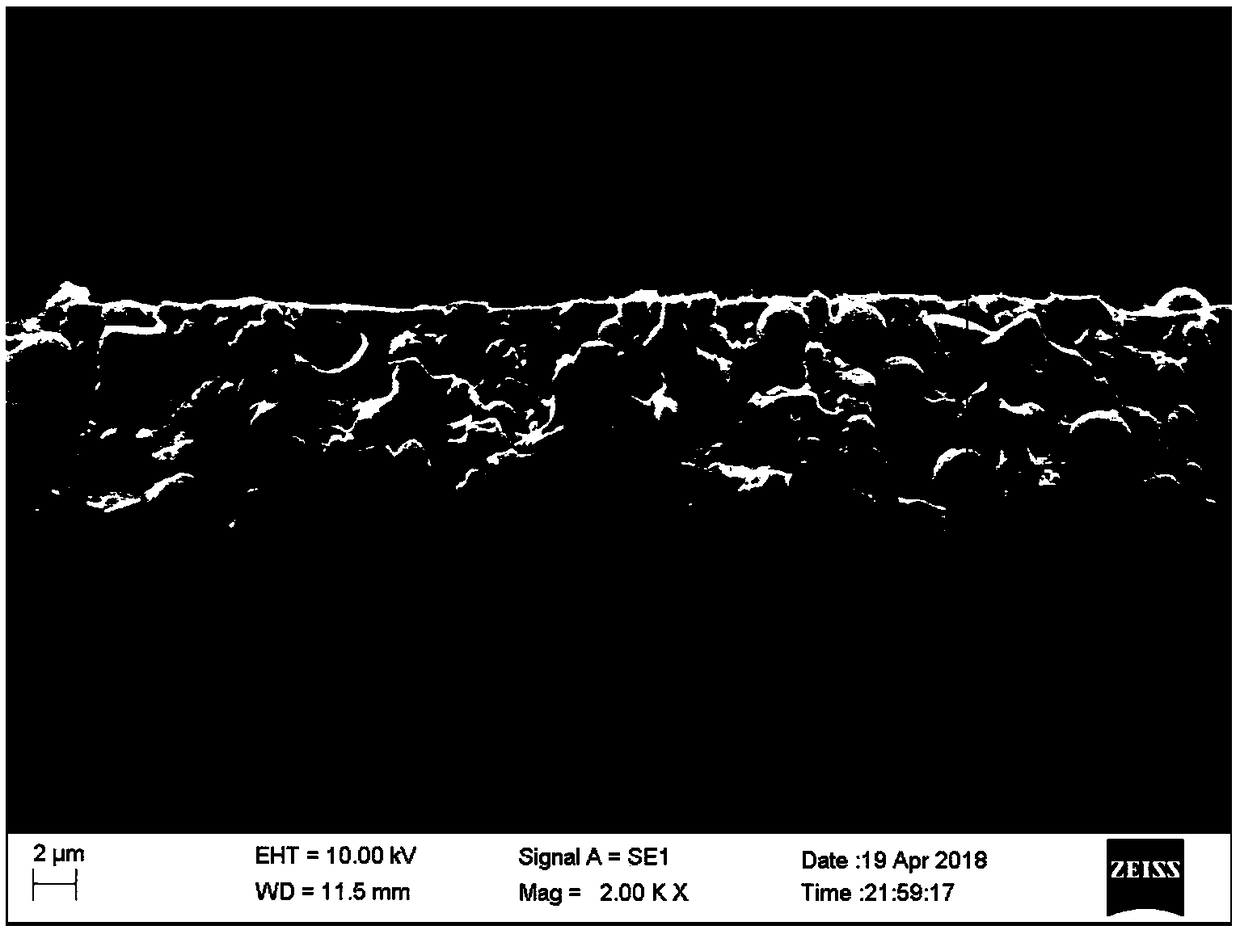

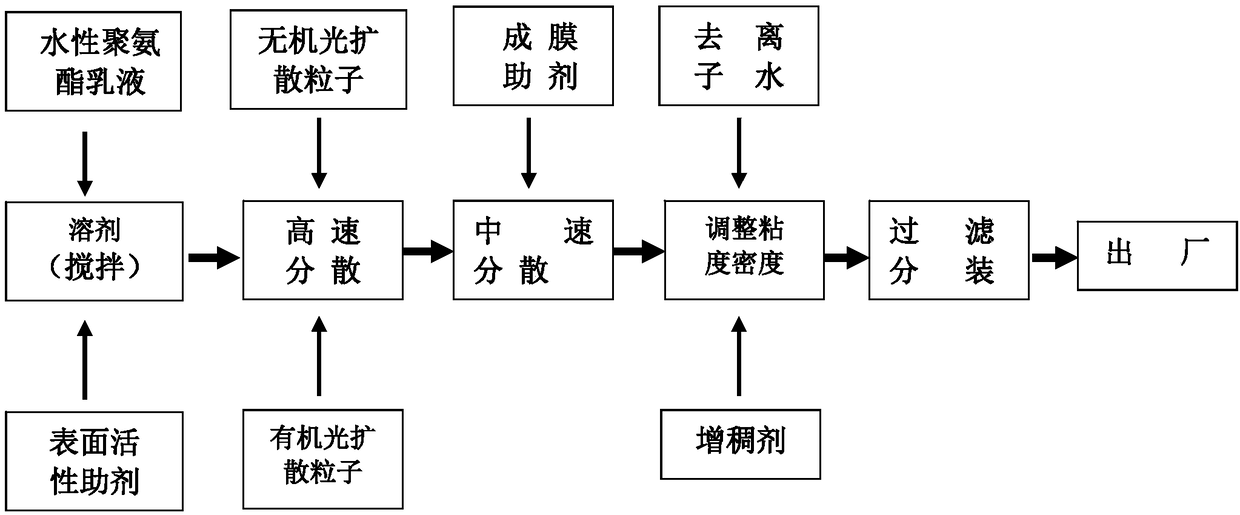

[0080] This embodiment provides a water-based light-diffusing coating, a water-based low-loss light-diffusing film and a preparation method thereof. The raw material proportions of the water-based light-diffusing coating and the water-based low-light-loss light-diffusing film are shown in Table 1, and the preparation process is as follows: image 3 , 4 shown.

[0081] (1) Preparation of water-based light-diffusing coatings

[0082] (1) Slowly pour the emulsion of the water-based polyurethane resin, the wetting and dispersing agent FX365, the defoamer TEGO902 and the leveling agent Surfynol 440 into a tank filled with industrial pure water at room temperature, and disperse for 10 minutes at a speed of 1500rpm ~15min;

[0083] (2) Add the water-based organic light-diffusing microparticles and inorganic light-diffusing microparticles at room temperature, disperse at a speed of 1600 rpm for 15 minutes, and then disperse at a speed of 3500 rpm for 60 minutes;

[0084] (3) Slowly ...

Embodiment 2

[0096] This embodiment provides a water-based light-diffusing coating, a water-based low-loss light-diffusing film and a preparation method thereof. The raw material proportions of the water-based light-diffusing coating and the water-based low-light-loss light-diffusing film are shown in Table 1, and the preparation process is as follows: image 3 , 4 shown.

[0097] (1) Preparation of water-based light-diffusing coatings

[0098] The types and mass ratios of raw materials are shown in Table 1, and the preparation process is the same as in Example 1.

[0099] (2) Preparation of water-based low light loss light diffusion film

[0100] (A) Mix the adhesive CS-555 and the water-based light-diffusing coating prepared in step (1), stir evenly, disperse at 800 rpm for 15 minutes, and filter the coating with a 300-mesh filter;

[0101] (B) Apply the filtered paint to the inner wall of the T5 4ft LED glass tube by flow coating (or spray coating or suction coating, etc.);

[0102...

Embodiment 3

[0110] This embodiment provides a water-based light-diffusing coating, a water-based low-loss light-diffusing film and a preparation method thereof. The raw material proportions of the water-based light-diffusing coating and the water-based low-light-loss light-diffusing film are shown in Table 1, and the preparation process is as follows: image 3 , 4 shown.

[0111] (1) Preparation of water-based light-diffusing coatings

[0112] The types and mass ratios of raw materials are shown in Table 1, and the preparation process is the same as in Example 1.

[0113] (2) Preparation of water-based low light loss light diffusion film

[0114] (A) Mix the adhesive CS-555 and the water-based light-diffusing coating prepared in step (1), stir evenly, disperse at 800 rpm for 15 minutes, and filter the coating with a 300-mesh filter;

[0115] (B) pour the filtered paint into the glass tube or spray (press-coat) it into the glass tube, and fill it up;

[0116] (C) Hang the ∩ glass tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com