Rapeseed oil pressing residue filter equipment

A press filter, rapeseed oil technology, applied in the direction of edible oil/fat, fat oil/fat refining, fat production, etc., can solve the problems of low slag removal efficiency, short storage time, human injury, etc. Clean, damage-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

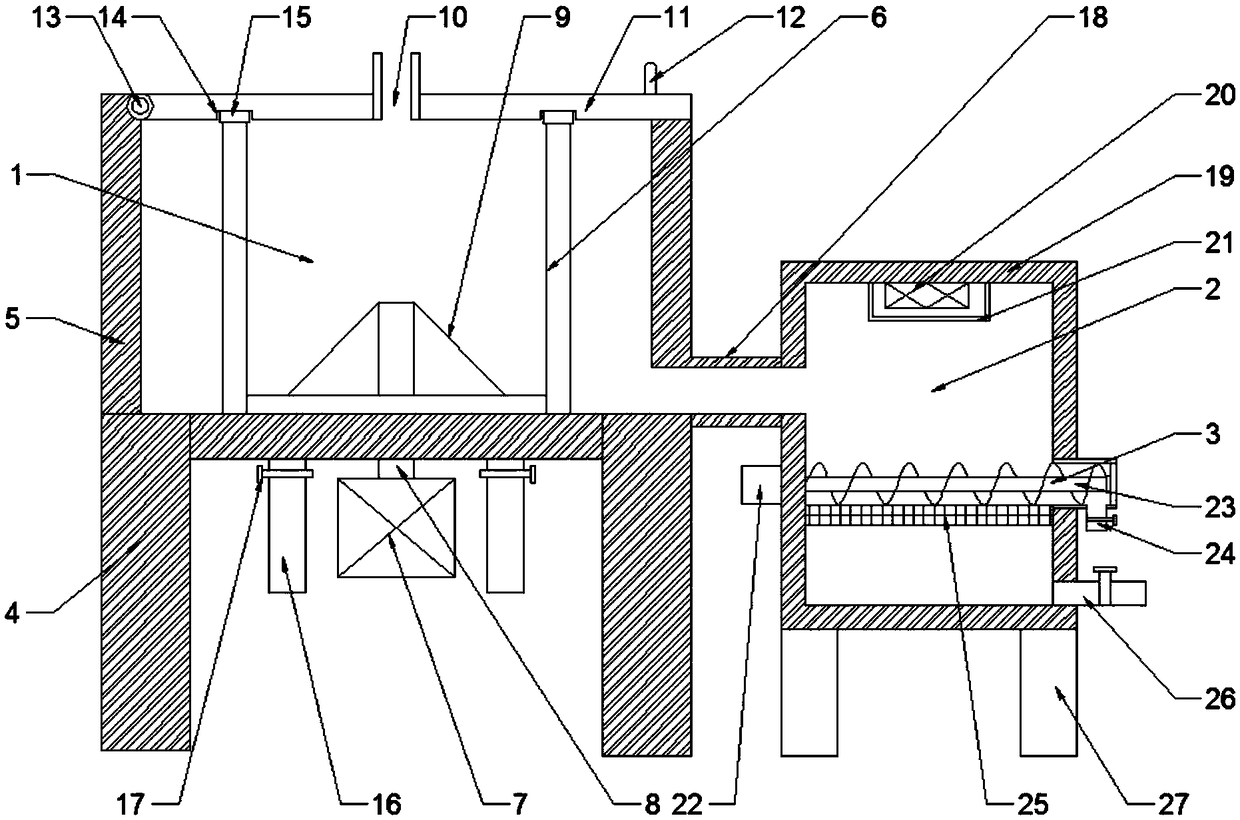

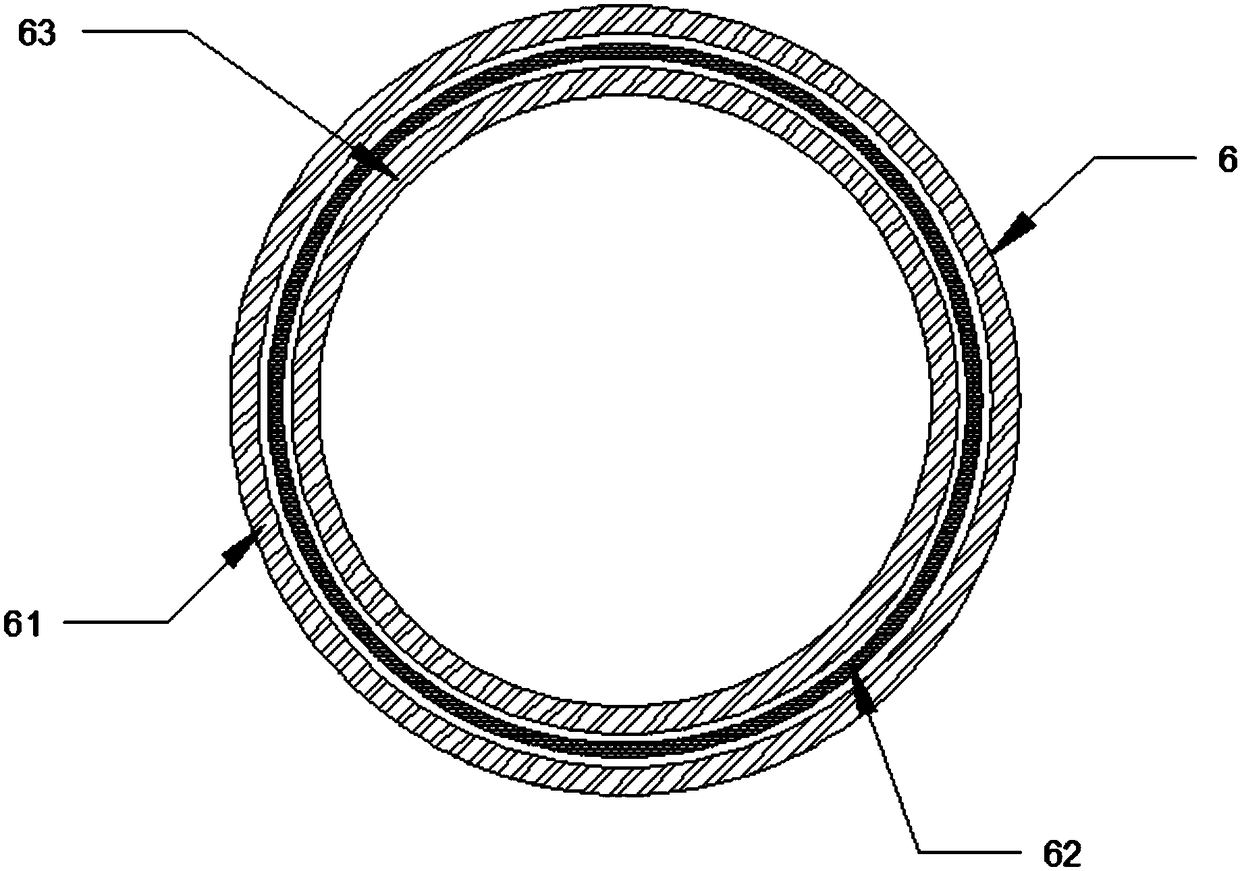

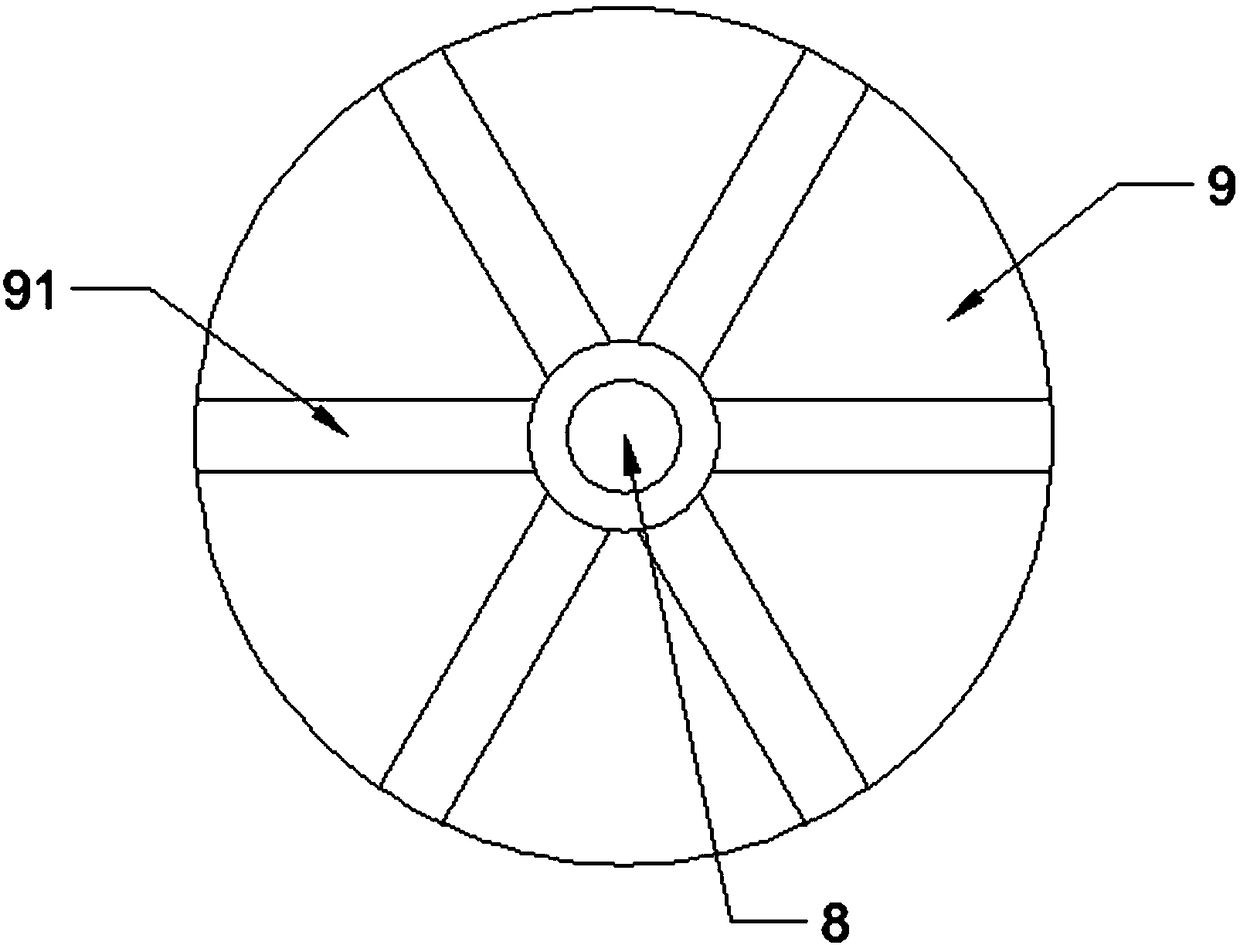

[0019] Such as Figure 1-Figure 3 As shown, a kind of rapeseed oil pressing filter residue equipment that the present invention proposes comprises stirring device 1, filtering device 2 and stirring box body 5, stirring device 1 connects filtering device 2 through connecting pipe 18, and stirring box body 5 lower end is provided with Pillar 4, a cover plate 11 is provided at the upper end of the stirring box body 5, a feed inlet 10 is provided at the middle part of the cover plate 11, a handle 12 is provided at the upper end of the right side of the cover plate 11, and the cover plate 11 is connected to the stirring box body 5 through a rotating shaft 13, and the cover plate The fixed groove 14 at the lower end of the plate 11 is provided with a filter barrel 6 below the fixed groove 14, and a stirring plate 9 is arranged at the bottom of the filter barrel 6. The stirring plate 9 is connected to the transmission shaft 8, and the transmission shaft 8 runs through the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com