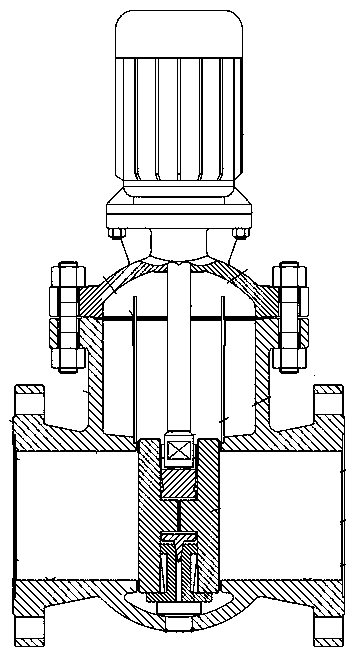

Double-wing-plate strong support pressure-reducing gate valve

A double-wing plate and gate valve technology, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems that the ball cannot be accurately aligned with the valve seat, failure, spring performance degradation, etc., and achieve the effect of convenient daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

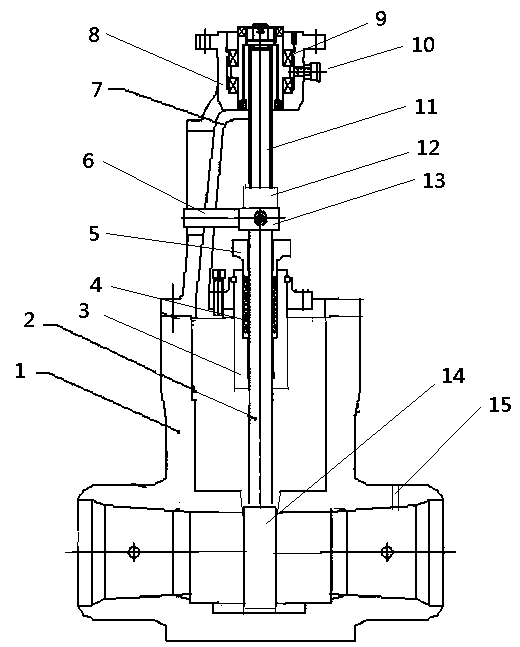

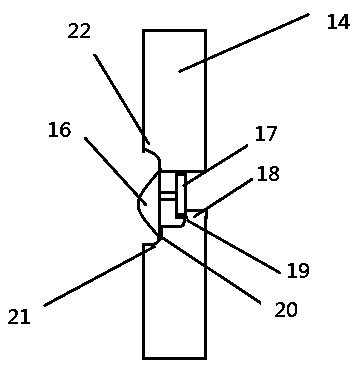

[0034] As shown in the figure: a double-wing plate strongly supported pressure reducing gate valve, the pressure reducing gate valve includes a valve body, a lower valve stem, a stuffing box, packing, a packing gland, a valve stem support frame, a bracket, a flange, a bearing, a lubricating Nozzle, upper valve stem, support ring, support seat, gate, sampling hole, umbrella wing, plate wing, first step, first arc, second step, second arc, third arc; above the valve body There is a bracket, the valve body and the bracket are connected by bolts, there is a flange on the top of the bracket, a stem support frame in the middle of the bracket, a support seat at the end of the valve stem support frame, a support ring above the support seat, and two upper and lower sides of the support ring. The upper and lower valve stems are respectively sleeved on the upper and lower valve stems, and the upper valve stem and the lower valve stem are threaded, and the relative positions of the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com