Horizontal multi-source steam waste heat recovery energy-saving device

A technology of steam waste heat and energy-saving device, applied in the field of horizontal waste heat recovery device and energy-saving device, can solve the problems of insufficient utilization of waste steam, difficult temperature matching, affecting production efficiency, etc., and achieve significant energy-saving effect, stable operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

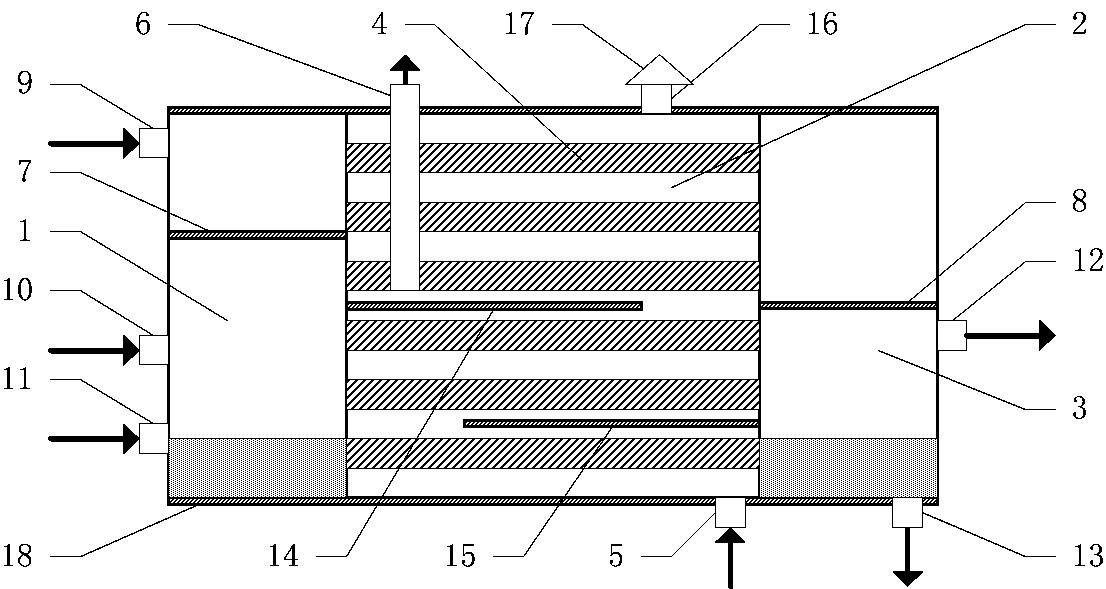

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] Such as figure 1 Shown is a schematic structural diagram of a horizontal multi-source steam waste heat recovery energy-saving device. figure 1 Among them, the device includes a steam inlet chamber (1), a heat exchange chamber (2), a steam outlet chamber (3), a column tube (4), a liquid inlet (5), a liquid outlet pipe (6), a first compartment Steam plate (7), second steam separator (8), first steam inlet (9), second steam inlet (10), condensed water inlet (11), waste gas outlet (12), condensed water outlet (13) , Upper liquid barrier (14), lower liquid barrier (15), breathing port (16), dust cover (17), insulation layer (18).

[0024] The liquid to be heated is generally clean water, which enters from the bottom right side of the heat exchange chamber (2) through the liquid inlet (5), and is blocked by the lower liquid baffle (15), flows to the left first, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com