Particle flow parameter measuring device and method based on laser backward scattering method

A backscattering method and flow parameter technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of optical path deviation, affecting the measurement accuracy, and the large size of the optical probe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Below in conjunction with accompanying drawing, the present invention is described in detail:

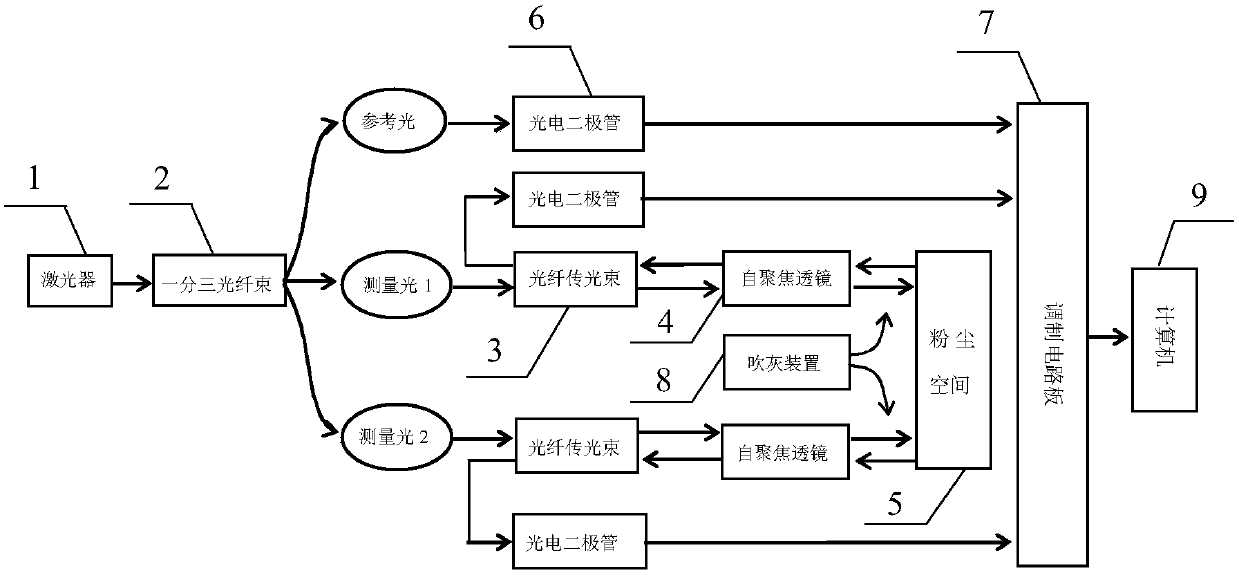

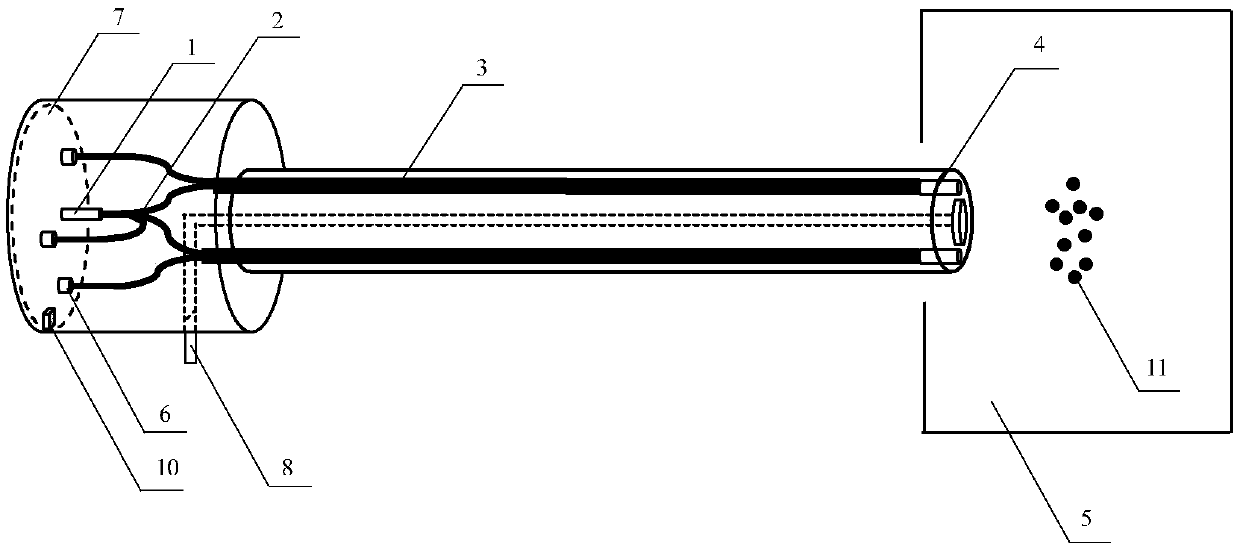

[0087] The present invention is a particle flow parameter measurement device based on laser backscattering method, such as figure 1 , figure 2 shown, including:

[0088] The device used to measure particle flow parameters includes a 635nm semiconductor laser 1, a split-three optical fiber bundle 2, an optical fiber transmission beam 3, a self-focusing lens 4, a dust space 5, a photodiode 6, a modulation circuit board 7, a soot blowing device 8 and a computer 9. Wherein the soot blowing device 8 and the computer 9 are external devices, and other devices are enclosed in a cylinder structure. like figure 2 As shown, the front end is the optical probe; the back end is the chassis, where the system power supply, laser generation, photoelectric conversion, signal acquisition and processing are all completed.

[0089] The probe is the core part of the optical system, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com