MEMS sound transducer element and method for producing a MEMS sound transducer element

A technology of acoustic transducers and components, applied in the direction of electrostatic transducer speakers, electrostatic transducer microphones, transducer shells/cabinets/brackets, etc., can solve problems such as adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, preferred embodiments are described in more detail with reference to the drawings, in which elements having the same or similar function are provided with the same reference numerals. Subsequent method steps can also be carried out in an order different from that described. Also, some steps are optional.

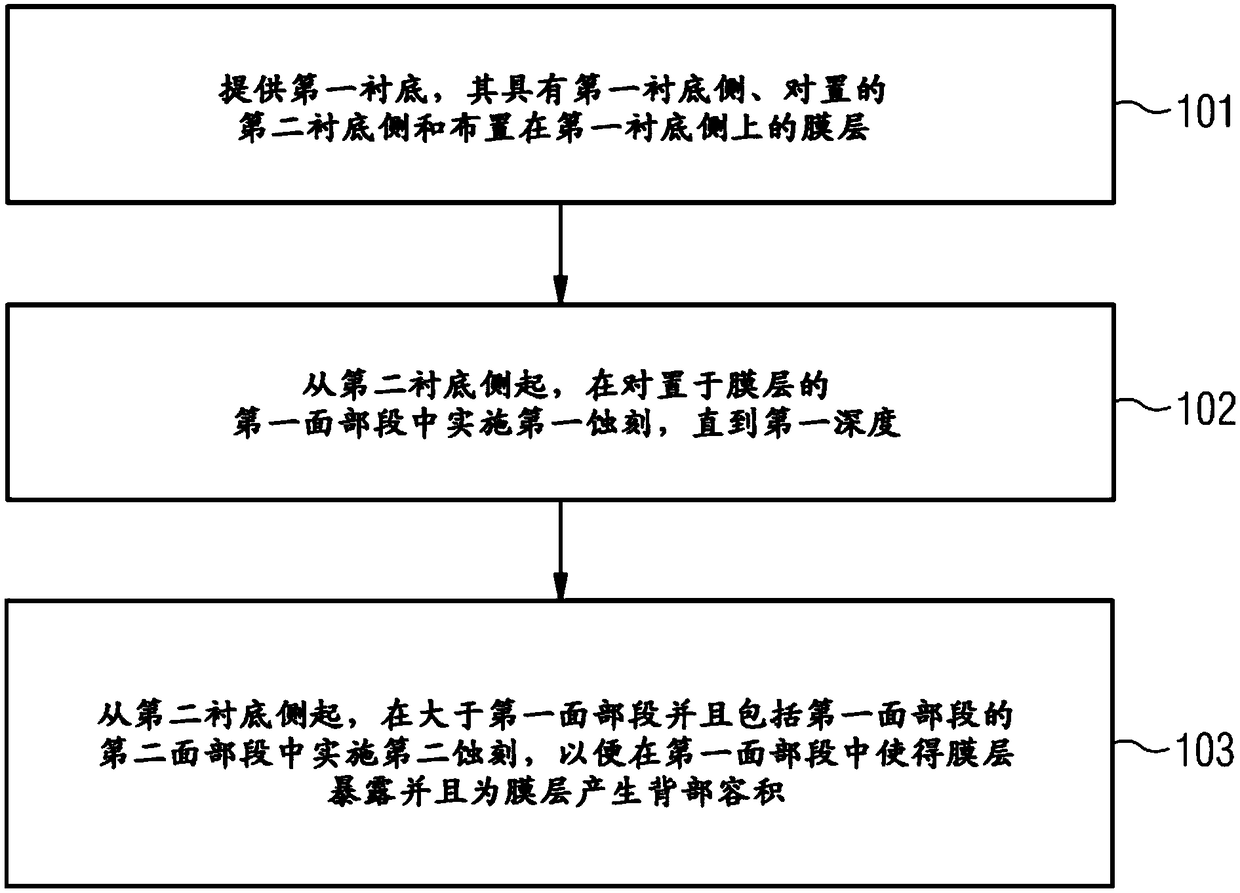

[0040] figure 1 A block diagram of a method for fabricating a MEMS acoustic transducer element according to the present disclosure is shown.

[0041] In block 101, a first substrate is provided having a first substrate side, an opposing second substrate side, and a film layer disposed on the first substrate side.

[0042] In block 102 , a first etching is carried out, starting from the second substrate side, in a first surface section opposite the membrane layer, down to a first depth.

[0043] In block 103, from the second substrate side, a second etch is performed in a second face segment larger than and including the first face segment to expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com