Composition, method of making composition, and article

A composition and polymer technology, applied in the direction of microsphere preparation, microcapsule preparation, coating, etc., can solve the problem of reduced light transmittance of windows, and achieve the effect of excellent peeling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] All parts, percentages, ratios, etc. in the examples, as well as in the remainder of this specification, are by weight unless otherwise indicated. All chemicals used in the examples are available from general chemical suppliers such as Sigma-Aldrich Corp., Saint Louis, Missouri, unless otherwise noted. In the examples, "% by weight" means percentage by weight, and "mol" means mole.

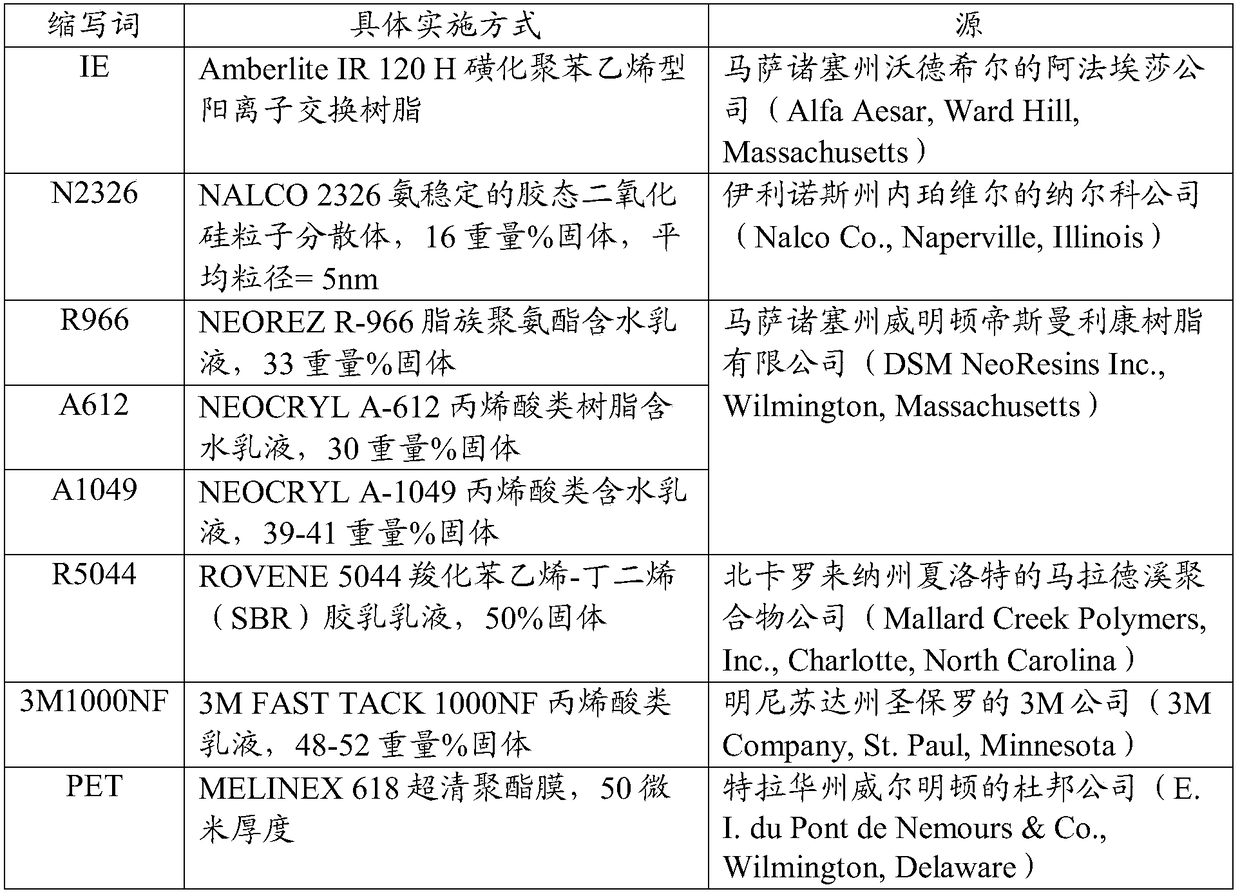

[0120] Table of materials used in the examples

[0121]

[0122] Tetramethoxysilane (TMOS), tetraethoxysilane (TEOS), methyltriethoxysilane (MTES), ethyltriethoxysilane (ETES), and vinyltriethoxysilane (VTES ) was purchased from Alfa Aesar, Ward Hill, Massachusetts (Alfa Aesar, Ward Hill, Massachusetts)

[0123] 3-Glycidoxypropyltrimethoxysilane, 3-(Acryloyloxypropyl)trimethoxysilane, Chloromethyltriethoxysilane, 5,6-Epoxyhexyltriethoxysilane, Phenyltriethoxysilane, diethylaminomethyltriethoxysilane, (2-triethoxysilylpropoxy)ethoxysulfolane were purchased from Gelest Inc., Tarrytown...

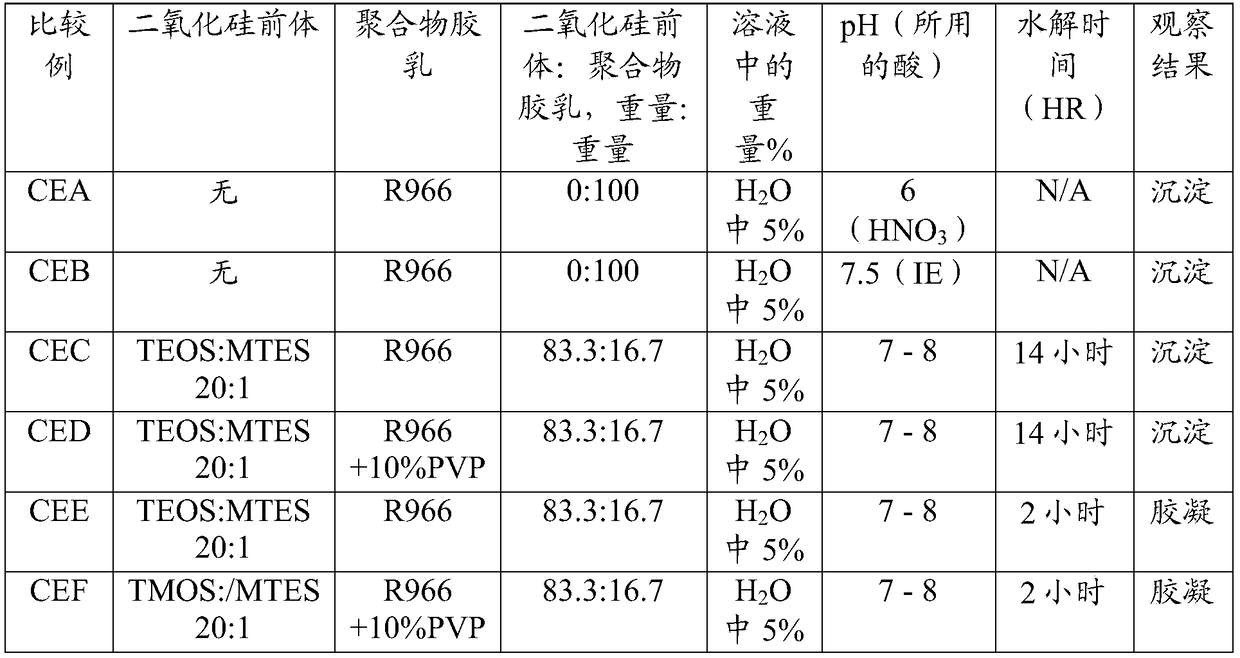

Embodiment 1-25 and comparative example CEI

[0196] Embodiment 1-25 and comparative example CEI-CEP

[0197] Comparative Examples I-P are commercially available polymer latex dispersions without colloidal silica particles as shown in Table 3.

[0198] Examples 1-25 were prepared by following the method for preparing composite particle dispersions - Method I or II. Examples prepared by the method of making composite particle dispersions - Method I and acidified to pH 2-4 using nitric acid are further denoted "A", while those acidified using acetic acid are further denoted "B". Examples prepared by the method for preparing composite particle dispersions - Method II and acidified to pH 2-4 using IE ion exchange resins are further denoted as "C".

[0199] Examples 1-10 were run using polymer latex R966 and the functionalized silica particle dispersions from Preparations 2-9. Silica: % by weight of polymer latex, acidification process and pH change as reported in Table 3.

[0200]Examples 11-21 were run in the same manne...

Embodiment 26C-27

[0207] Embodiment 26C-27C and comparative example CEQ-CER

[0208] Comparative examples CEQ and CER are mixtures of functionalized silica particle dispersion PE2 and polymer latex without acidification. Comparative Example CER also contained PVP. The compositions and cumulative fitting results of comparative CEQ and CER composite particles are reported in Table 4.

[0209] Examples 26C-27C are composite particles made from a dispersion of functionalized silica particles from PE2 and acidification (by ion exchange to pH 2) of the polymer latex through a self-assembly process. The compositions and cumulative fit results for the composite particles of Examples 26C-27CC are reported in Table 4.

[0210] To demonstrate the reversibility of the composite particles and process of the present disclosure, the Example 26C-27C dispersions (pH 2) were titrated to pH 10 with ammonia, and the cumulative fit results for the resulting composite particles were measured and reported in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com