Photosensitive resin composition, photosensitive element using same, method for forming resist pattern, method for producing lead frame, printed wiring board, and method for producing printed wiring board

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition, can solve problems such as hard-to-peel light tool workability, light tool pollution, reduction, etc., and achieve the effect of excellent peeling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0243] The following examples illustrate the present invention specifically, but the present invention is not limited by these examples. Here, "parts" and "%" are mass standards unless otherwise stated.

Synthetic example

[0245] (Synthesis of Binder Polymer (A-1))

[0246] 150g of methacrylic acid, 125g of benzyl methacrylate, 25g of methyl methacrylate and 200g of styrene (mass ratio 30 / 25 / 5 / 40) as a polymerizable monomer (monomer), and azobisisobutyl 9.0 g of nitriles were mixed to prepare solution a.

[0247] Solution b was prepared by dissolving 1.2 g of azobisisobutyronitrile in 100 g of a mixed solution (mass ratio 3:2) of 60 g of methyl cellosolve and 40 g of toluene.

[0248] In a flask equipped with a stirrer, a reflux condenser, a thermometer, a dropping funnel, and a nitrogen gas introduction tube, 450 g of a mixed solution (mass ratio 3: 2) of 270 g of methyl cellosolve and 180 g of toluene was dropped, and nitrogen gas was blown into the flask. While stirring, the temperature was raised to 80°C.

[0249] After adding the above-mentioned solution a dropwise to the above-mentioned mixed liquid in the flask over 4 hours, the mixture was kept at 80° C. for 2 hours while stirring. Ne...

Embodiment 1~11 and comparative example 1~4

[0266] [Preparation of Photosensitive Resin Composition]

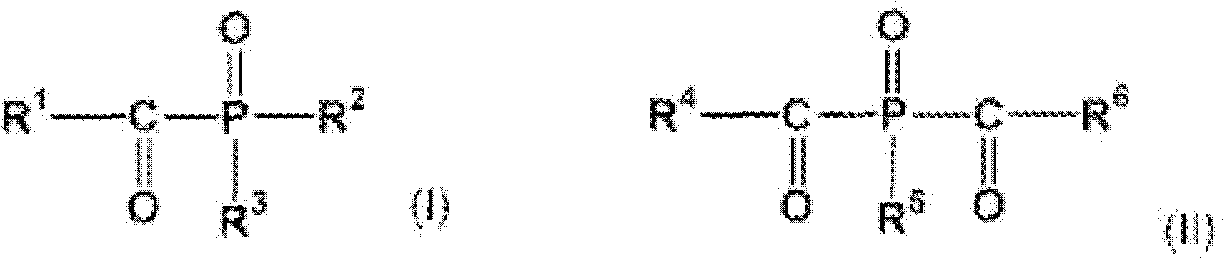

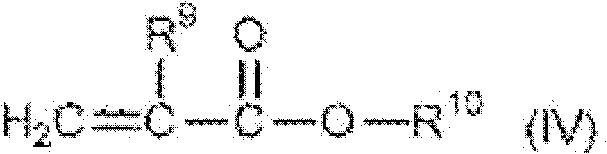

[0267] A-1 to A-6 obtained above were used as (A) binder polymer, B-1 to B-4 shown below as (B) polymerizable compound, and as (C) photopolymerization initiator C-1A, C-1B, and C-2 shown below of the agent, and the ingredients shown below as other components were mixed according to the compounding amounts (parts to be compounded) shown in the following Table 2, thereby preparing respectively The photosensitive resin composition of Examples 1-11 and Comparative Examples 1-4. Here, the compounding quantity (compounding part) of (A) binder polymer shown in Table 2 is the mass (solid content quantity) of a non-volatile component.

[0268] (B) Photopolymerizable compound

[0269] B-1: 2,2-bis(4-(methacryloyloxypentaethoxy)phenyl)propane [FA-321M (manufactured by Hitachi Chemical Industries, Ltd., product name)]

[0270] B-2: 2,2-bis(4-((meth)acryloyloxydipropoxy)phenyl)propane [BPE-200 (manufactured by Shin-Nakamura Chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com