Polarizing plate, polarizing plate-carrier film laminate, method for preparing polarizing plate-carrier film laminate, method for preparing polarizing plate and active energy ray curable composition

An active energy ray, polarizing plate technology, applied in chemical instruments and methods, applications, coatings, etc., can solve problems such as tearing of polarizers, and achieve the effects of improving bonding strength, improving workability, and inhibiting blocking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0207] The preparation of the carrier film may also include providing a primer layer on one or both surfaces of the carrier film by applying and drying the water-dispersible primer composition on one or both surfaces of the carrier film on the carrier film .

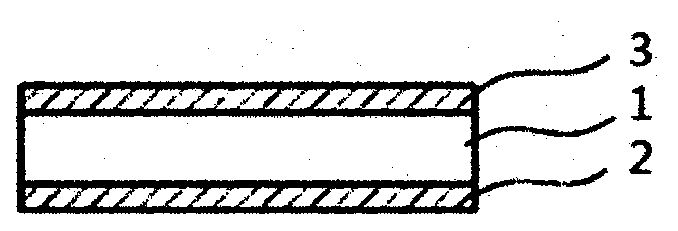

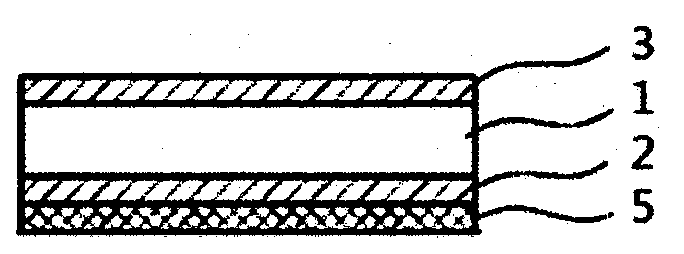

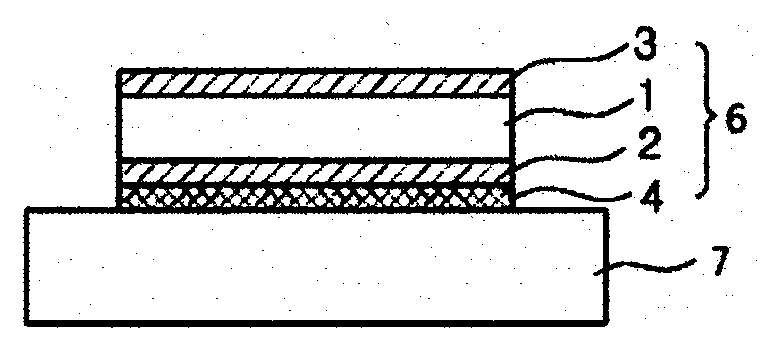

[0208] In the method for manufacturing a polarizing plate according to an exemplary embodiment of the present specification, the film supply process includes: supplying the carrier film 200 on one surface of the polarizer 100; Protective film 300. Specifically, the method may be performed as a method of supplying the carrier film 200 on one surface of the polarizer 100 and simultaneously supplying the protective film 300 on the other surface of the polarizer 100 .

[0209] A method of supplying the polarizer 100, the carrier film 200, and the protective film 300 may be performed by using a method known in the art. For example, a polarizer, a carrier film, and a protective film may be supplied in a form in which each fi...

Embodiment approach

[0276] Hereinafter, the specification will be described in more detail through examples. However, the following examples are provided to illustrate the present specification, and the scope of the present specification is not limited thereby.

preparation example 1

[0279] (1) Preparation Example 1: Production of Photocurable Composition A for Forming a Protective Layer

[0280] Based on 100 parts by weight of 3,4-epoxycyclohexylmethyl-3',4'-epoxycyclohexane carboxylate (which is an epoxy compound without an aromatic ring) 18 parts by weight of bis Phenol F type epoxy compound (trade name YDF-170), 3-ethyl-3-[(3-ethyl oxetane-3-yl) methoxymethyl] oxygen heterocycle of 54 parts by weight Butane (Aron Oxetane OXT-221 manufactured by Toagosei Co., Ltd.), which is an oxetane compound, and 9 parts by weight of polycaprolactone triol (trade name PLACCEL 305) were mixed to produce a composition . The active energy ray curable composition A is produced by mixing 2 to 3 parts by weight of Irgacure 250 as a photoinitiator and 1 part by weight of ESACURE ITX as a photosensitizer based on 100 parts by weight of the composition. In this case, the active energy ray-curable composition A had a viscosity of 100 cps at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com