Compressive sintering flue gas desulfurization and denitrification and flue gas white vapor elimination treatment system and process

A sintering flue gas, desulfurization and denitrification technology, applied in the field of sintering flue gas treatment, can solve problems such as failure to raise flue gas temperature, difficulty in achieving standard emission of flue gas, and difficulty in performing SCR denitrification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

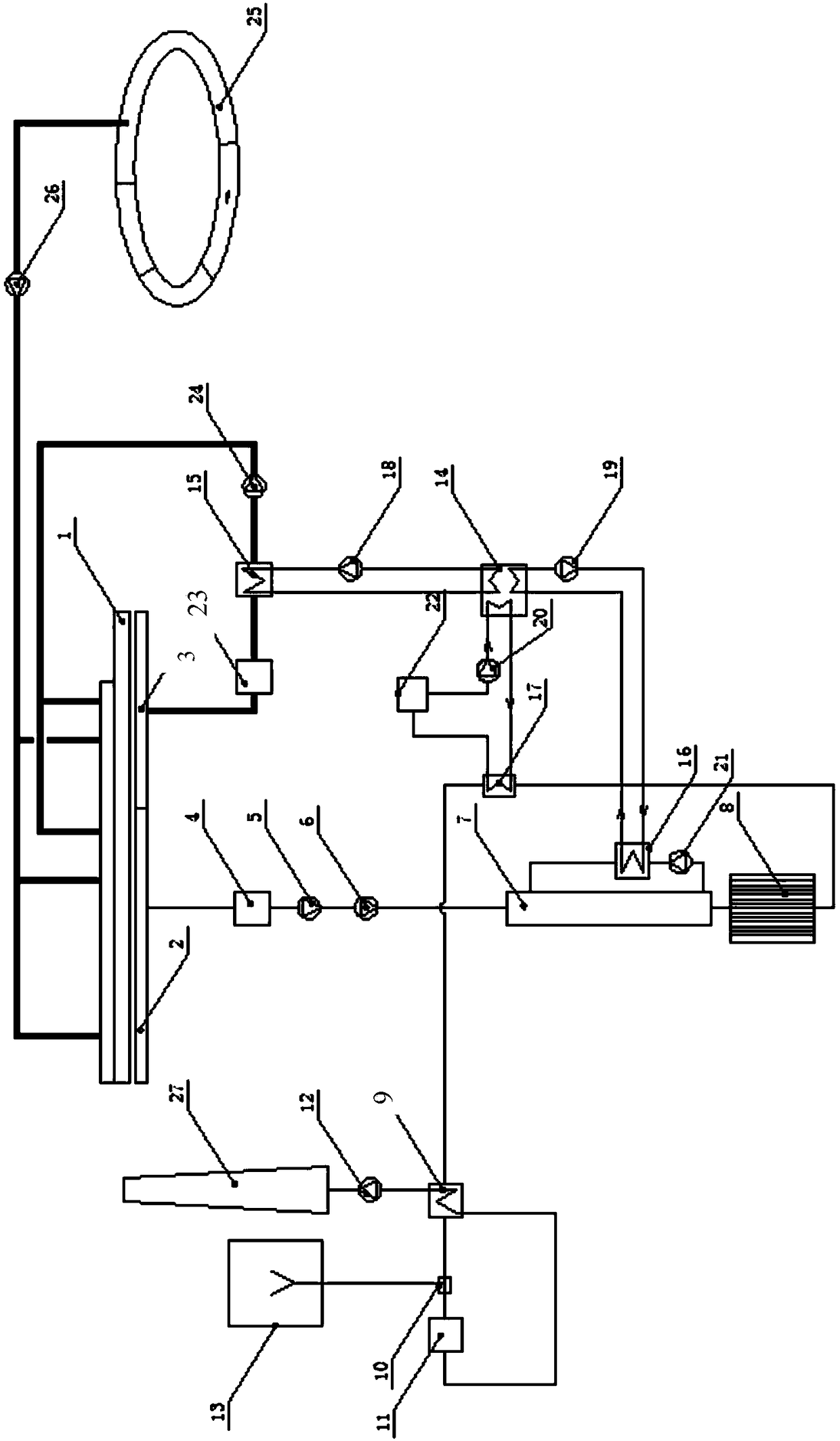

[0073] This embodiment provides a comprehensive treatment system for sintering flue gas desulfurization, denitrification, and flue gas whitening. The structural diagram of the system is as follows figure 1 shown, from figure 1 It can be seen from the figure that the system includes a sintering machine 1, a wet desulfurization tower 7, a denitrification system and a sintering cooler 25, wherein the comprehensive treatment system for sintering flue gas desulfurization, denitrification, and flue gas elimination also includes a second dust collector 23. The convection heat exchanger 15 and the induced draft fan 24. The flue gas outlet of the high-temperature section 3 of the sintering dust fall pipe of the sintering machine 1 passes through the pipeline in sequence through the second dust collector 23, the convective heat exchanger 15, the induced draft fan 24 and the The upper part of the sintering material layer of the sintering machine 1 is connected;

[0074] The comprehensiv...

Embodiment 2

[0086] This embodiment provides a comprehensive treatment process for sintering flue gas desulfurization, denitrification, and flue gas whitening, wherein the process is realized by using the comprehensive treatment system for sintering flue gas desulfurization, denitrification, and flue gas whitening provided in Example 1. Described technique comprises the following specific steps:

[0087] The flue gas produced during the sintering process of the sintering machine enters the dust fall pipe. The flue gas in the falling dust pipe is divided into two parts, one is the sintering low-temperature wet flue gas near the head of the sintering machine, and the other is the high-temperature flue gas near the sintering machine;

[0088] a. The sintering high-temperature flue gas is dedusted in the second dust collector, and then the flue gas obtained after dedusting is subjected to heat exchange in a convection heat exchanger, and the temperature of the sintering high-temperature flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com