Hybrid commercial vehicle thermal management using dynamic heat generator

A heat generator, hybrid electric technology, applied in hybrid vehicles, engine-driven traction, arrangement of multiple different prime movers of general power plants, etc., can solve the requirement of less or no extension of front length And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

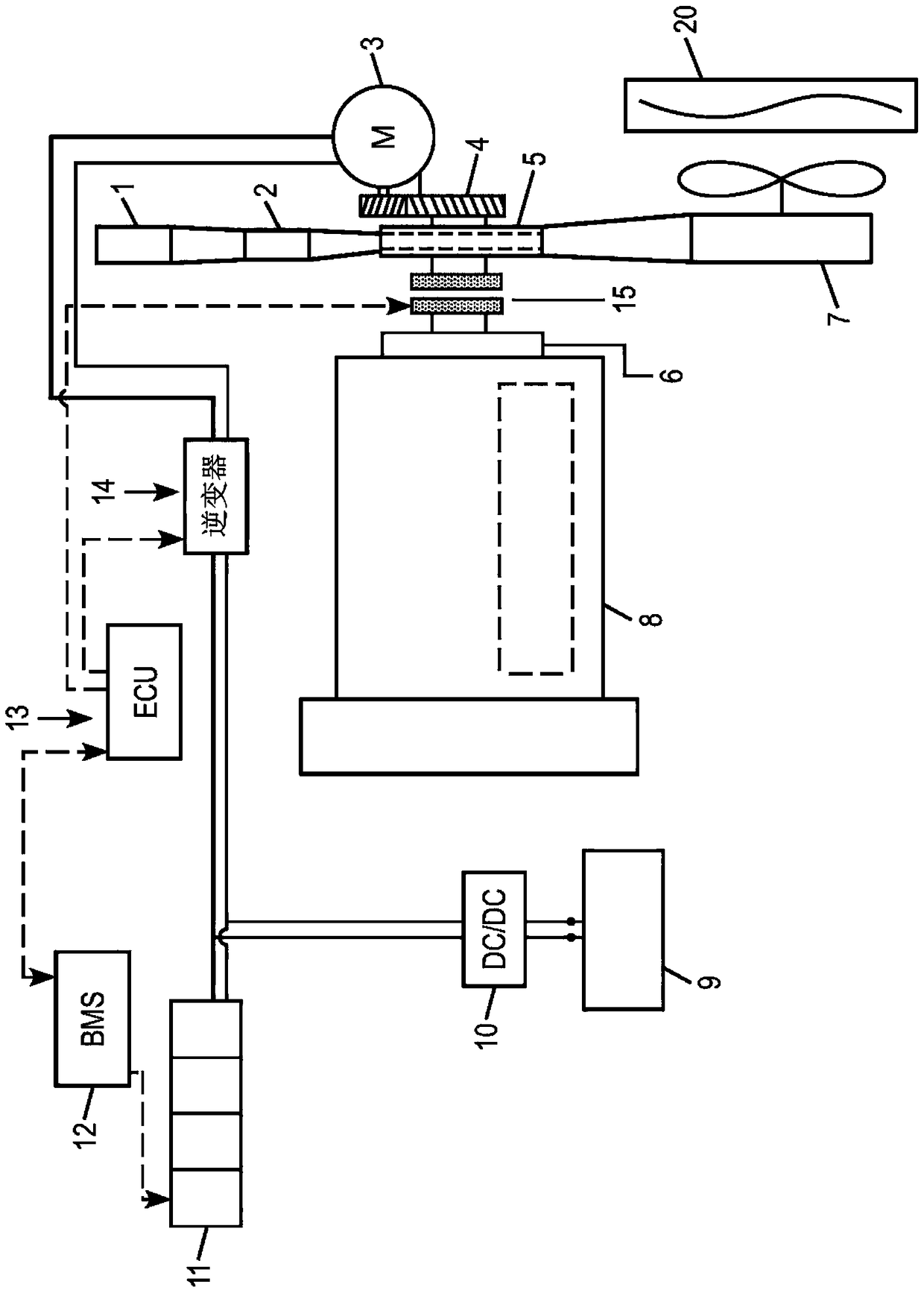

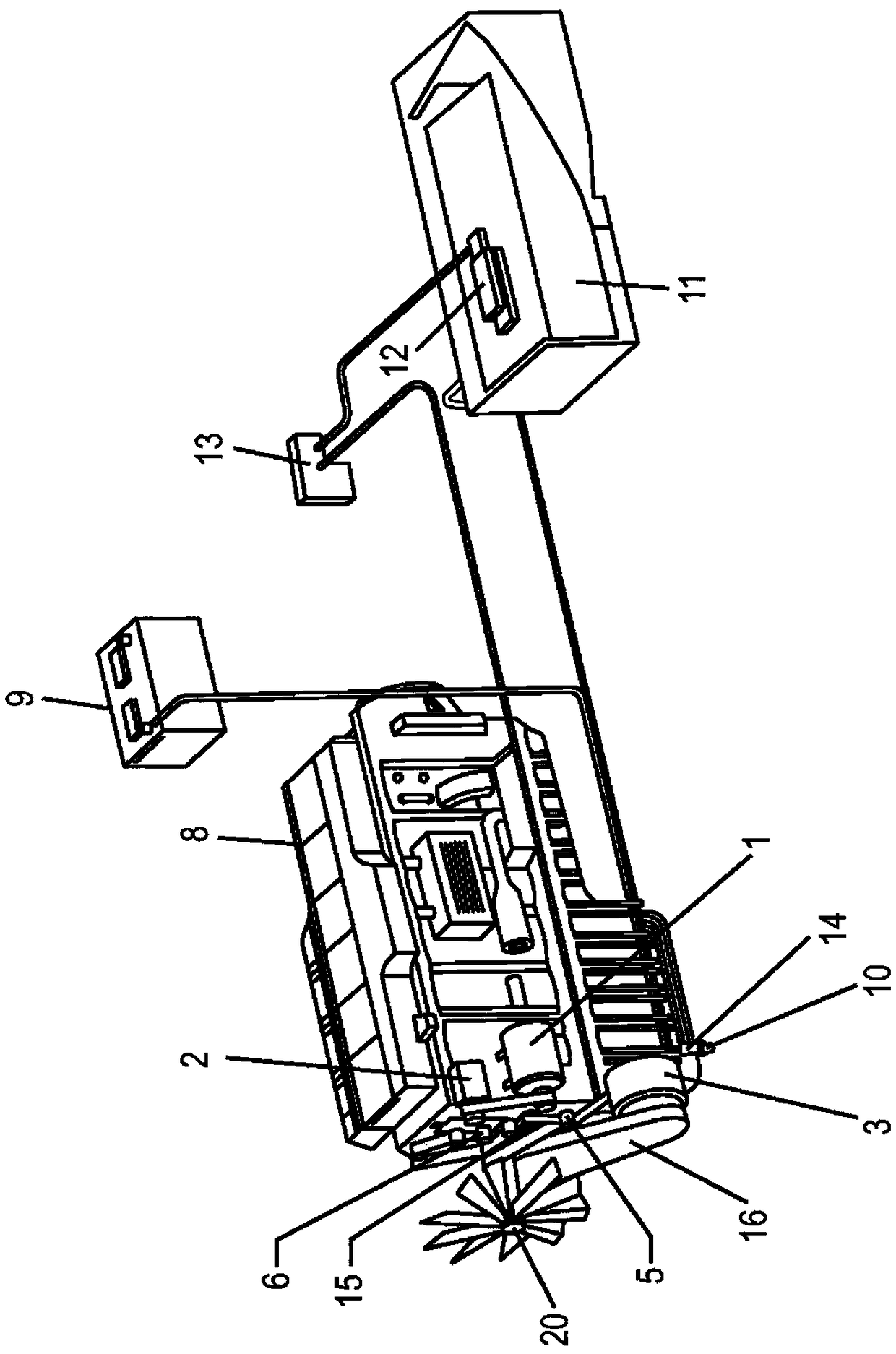

[0094] Front end motor generator system embodiment.

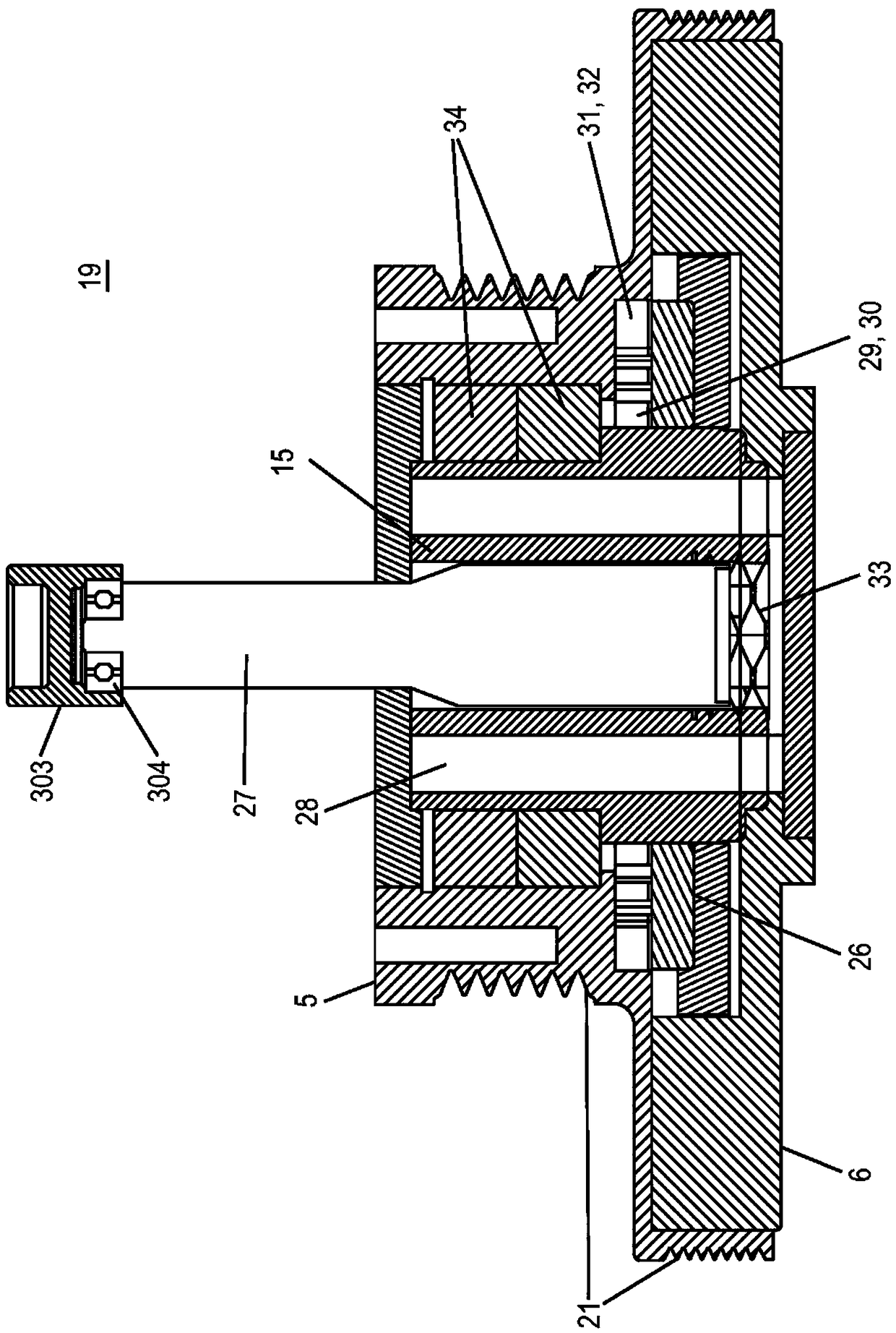

[0095] Figure 1A is a schematic diagram illustrating components of an embodiment of a FEMG system according to the present invention. Figure 1B is a schematic diagram of several FEMG system components in the chassis of a commercial vehicle. In this arrangement, the engine accessories, including the gas compressor 1 , the air conditioner compressor 2 and the engine cooling fan 7 arranged to draw cooling gas through the engine coolant radiator 20 , are driven by the pulley 5 . The pulley 5 is positioned coaxially with the damper 6 , which is directly coupled to the crankshaft of the internal combustion engine 8 . The accessories may be driven directly by the drive belt, or provided with their own on-off or variable speed clutches (not shown) which allow the separately clutched accessories to be partially or fully disengaged from the belt drive.

[0096] In addition to driving the accessory drive belt, a pulley 5 is couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com