Excavator dipper teeth and excavator with the same

A technology of excavator bucket teeth and bucket teeth, which is applied in the field of excavator and excavator bucket teeth, can solve the problems of limited space for improving the overall life of excavator bucket teeth, and achieve high cost performance, good hardening effect, and reduced cost of bucket teeth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The chemical composition of excavator bucket teeth and the weight percentage of each component are: C: 1.0%, Si: 0.30%, Mn: 23.0%, Al: 6.0%, B: 0.003%, RE (La and Ce mixed rare earth) : 0.30%, P<0.0015%, S<0.0015%, the balance is Fe.

[0044] Ingredients: Select high-quality broken steel sheets, ferrosilicon, recarburizer, pure manganese, pure aluminum, high-carbon ferrochromium, ferroboron, rare earth according to the alloy content;

[0045] Melting: Smelting crushed steel sheets in an intermediate frequency induction furnace, adding pure aluminum when the temperature of the molten steel reaches 1550~1580°C, adding carburant to adjust the C content, adding high-carbon ferrochrome, ferroboron, ferrosilicon, and pure manganese; After the alloy is fully melted, when the temperature reaches above 1580°C, take a sample and analyze the weight percentage of each element composition, mainly looking at C, P, S, and B. It is necessary to ensure that P and S are below the upper l...

Embodiment 2

[0052] Design composition and batching, smelting and casting molding steps are with embodiment 1, and difference is:

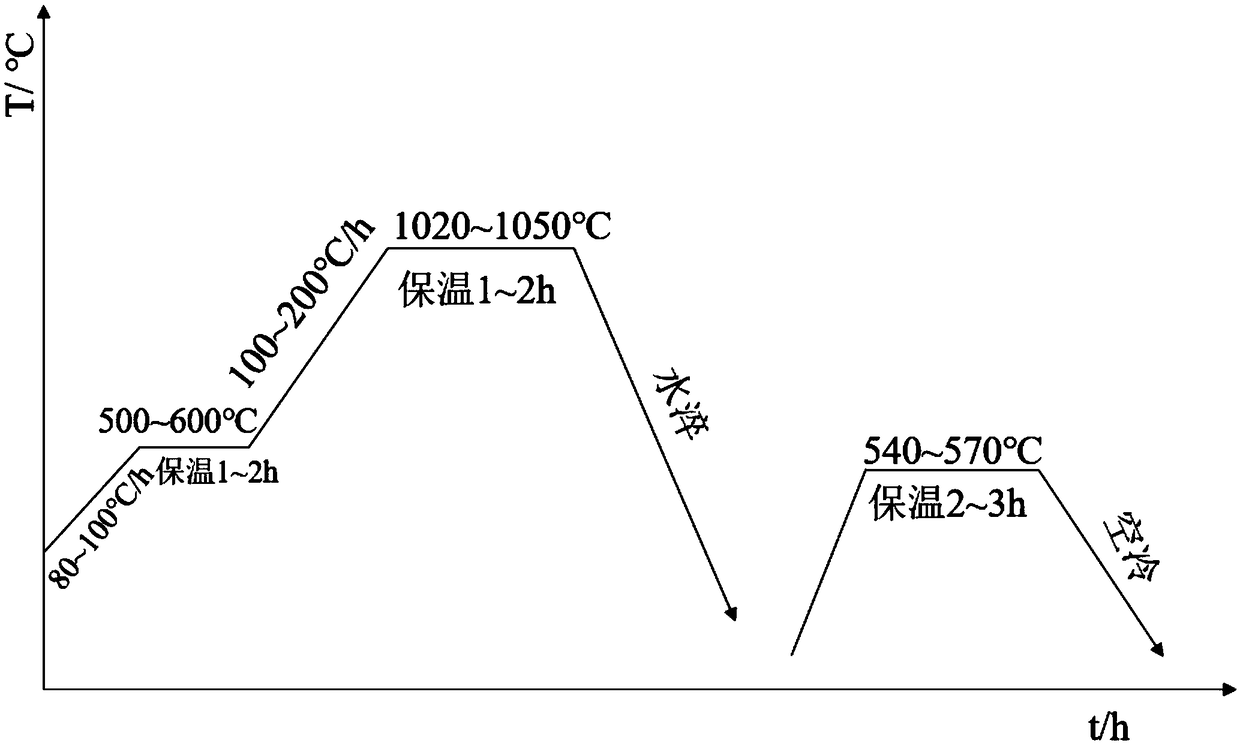

[0053] Precise heat treatment: use an electric furnace that can precisely control the heating rate, temperature, and holding time to heat the casting, heating from room temperature to 550 °C at a heating rate of 90 °C / h, and then heating from 550 °C to After heat preservation at 1040°C for 1.5h for water toughening treatment, heat preservation at 560°C for 2.5h for aging treatment, and then air-cool to room temperature;

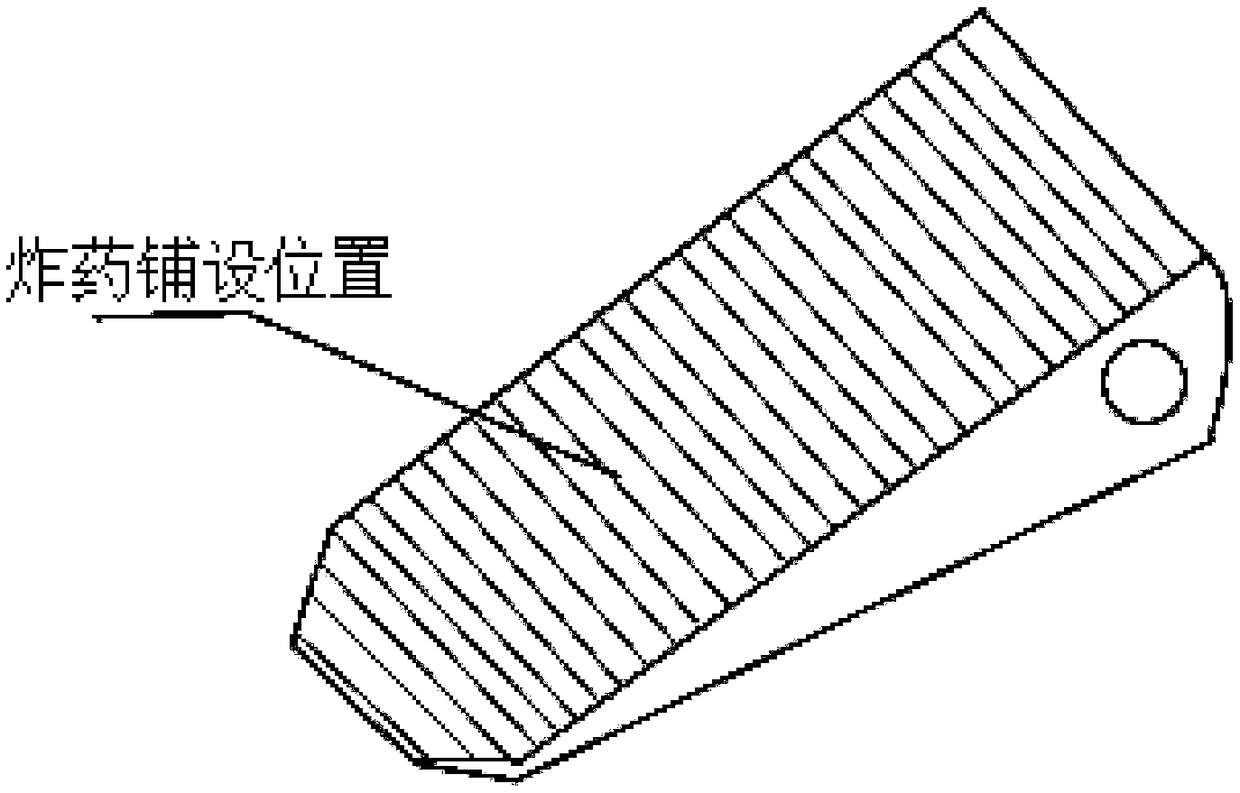

[0054] Surface blast hardening treatment: Spread 2.5mm thick explosives on the surface of excavator bucket teeth. The explosives are adhesive plastic explosives with a density of 1.42g / cm 3 , the detonation velocity is 7700m / s, and the No. 8 detonator is used for reliable primary detonation;

[0055] The surface hardness of excavator bucket teeth after explosion treatment is 400 HB, and the impact toughness (V-shaped notch) is 110J / cm 2 , t...

Embodiment 3

[0058] Design composition and batching, smelting and casting molding steps are with embodiment 1, and difference is:

[0059] Precise heat treatment: Use an electric furnace that can precisely control the heating rate, temperature, and holding time to heat the casting, heating from room temperature to 600 °C at a heating rate of 100 °C / h, and then heating from 600 °C to 600 °C at a heating rate of 200 °C / h After heat treatment at 1040°C for 1.5h for water toughening treatment, heat preservation at 560°C for 2.5h for aging treatment, and then air-cool to room temperature;

[0060] Surface blast hardening treatment: Spread 2.5mm thick explosives on the surface of excavator bucket teeth. The explosives are adhesive plastic explosives with a density of 1.42g / cm 3 , the detonation velocity is 7700m / s, and the No. 8 detonator is used for reliable primary detonation;

[0061] The surface hardness of excavator bucket teeth after blast treatment is 420 HB, and the impact toughness (V-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com