Flame-retardant antibacterial bed sheet fabric production method

A production method and fabric technology, which is applied in the direction of flame-retardant fibers, textile material carrier treatment, spray/jet textile material treatment, etc., can solve the problems of single function, no flame-retardant and antibacterial properties, single structure of bed sheet fabric, etc., to achieve Reasonable structural design, improved spraying efficiency, and the effect of improving the continuity of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

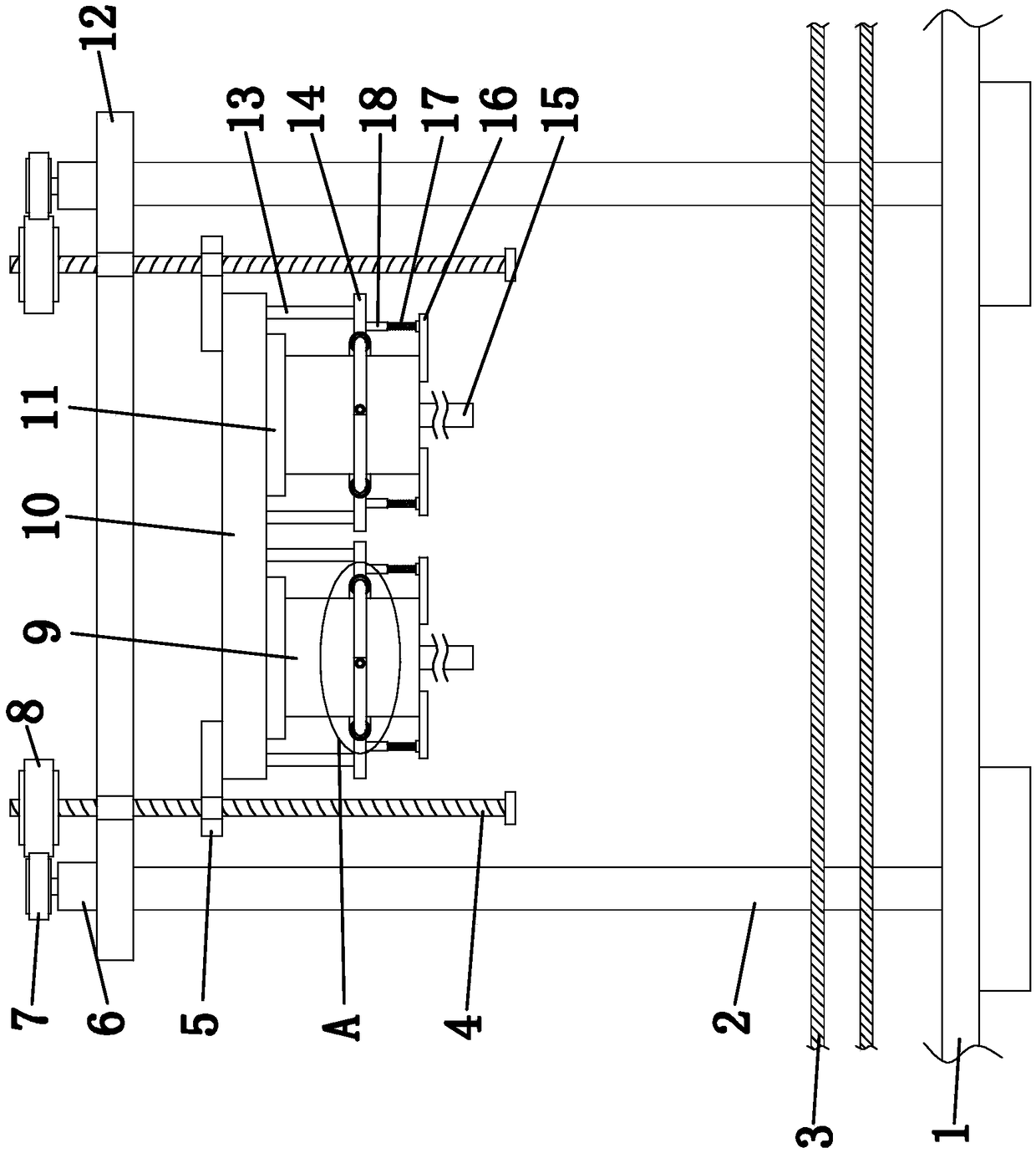

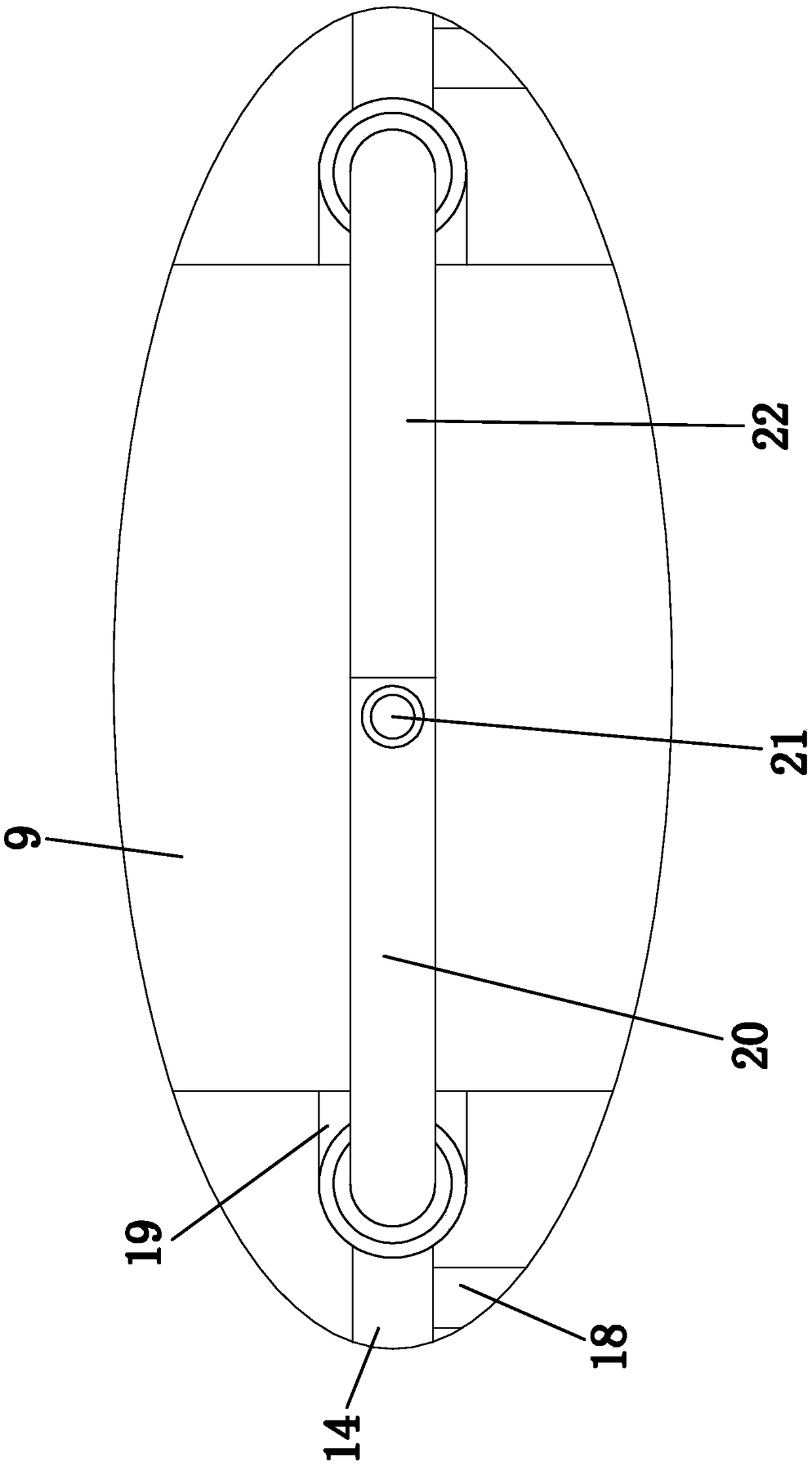

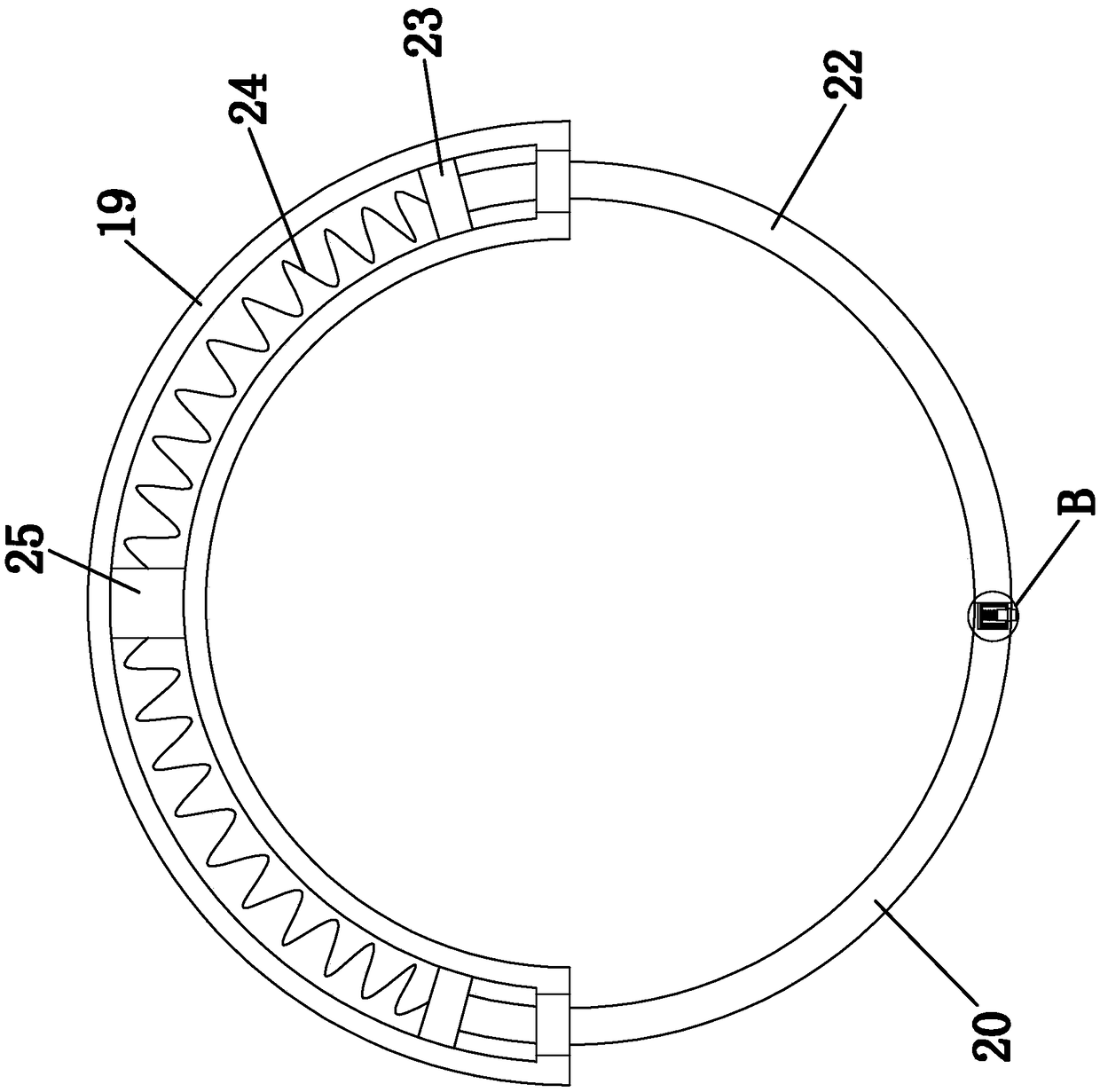

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0026] The preparation method of the flame retardant and antibacterial bed sheet fabric comprises the following steps: a. purchase the existing bed sheet fabric on the market; b. weigh raw materials in parts by weight: 6-10 parts of flame retardant, 3-7 parts of antibacterial agent , 0.6-1.2 parts of defoamer and 70-90 parts of water; c, put each raw material into the mixer, the stirring speed is 100-150rpm, the stirring time is 6-10min, and the material liquid is obtained; d, through the spraying equipment Spraying the material liquid onto the surface of the bed sheet and drying it; e. Washing the dried bed sheet and drying it naturally to obtain a finished flame-retardant and antibacterial bed sheet.

[0027] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com