A construction method of steel trestle bridge resisting the impact of flood discharge rapids

A construction method and steel trestle technology, which is applied to bridges, bridge construction, infrastructure engineering, etc., can solve problems such as long construction period, instability and collapse, and poor stability of steel trestles, so as to achieve good working environment and low capital investment , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

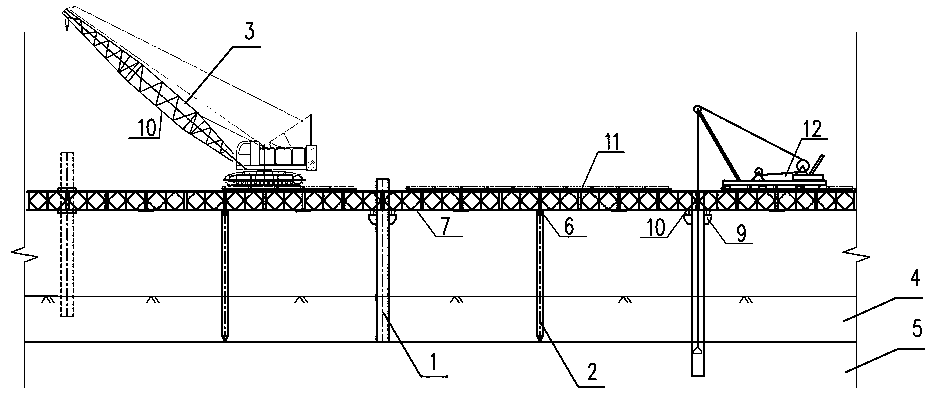

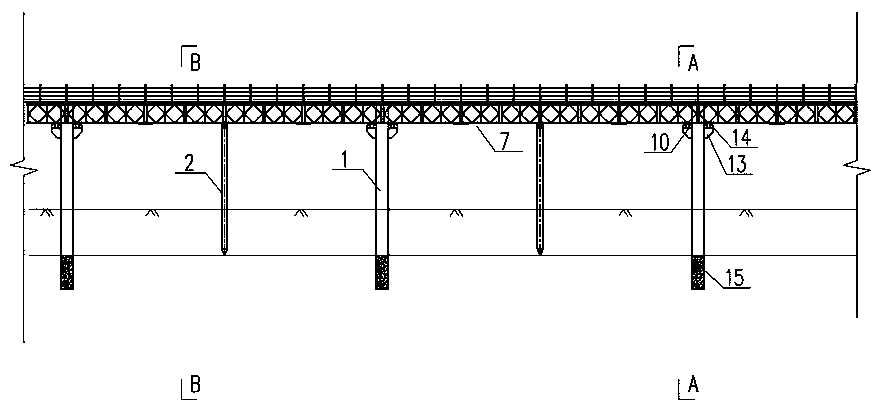

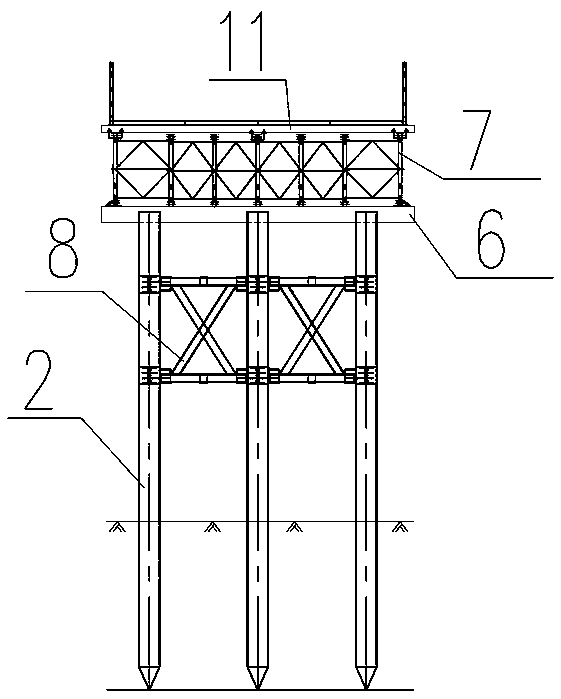

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0020] The steel trestle bridge construction method for resisting the impact of flood discharge rapids described in the present invention includes construction of underwater foundation setting and laying of assembled bridge deck, and the specific construction steps are:

[0021] In the first step, according to the design of the steel trestle bridge, prepare the type I steel pipe pile 1 with a diameter of 920mm and the type II steel pipe pile 2 with a diameter of 426mm. The groove of the beam (due to the different diameters of type I steel pipe pile 1 and type II steel pipe pile 2, correspondingly, the type of distribution beam placed on type I steel pipe pile 1 can be larger, while the type of distribution beam placed on type II steel pipe pile 2 The type of the distribution beam can be smaller, which not only needs to meet the load-bearing requirements of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com