Signal receiving circuit of electronic detonator

A signal receiving and electronic detonator technology, applied in fuzes, electrical components, weapon accessories, etc., can solve problems such as inability to meet full-cycle application requirements, insufficient compatibility and stability, complex structure of receiving circuits, etc., to meet full-cycle communication requirements, elimination of channel imperfections, and the effect of meeting low-voltage and high-voltage communication requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make it easier for those skilled in the art to understand the technical solution of this patent, and at the same time, in order to make the technical purpose, technical solution and beneficial effect of this patent clearer, and to fully support the protection scope of the claims, the following is a specific case in the form of this patent. The technical solution of the patent makes further and more detailed descriptions.

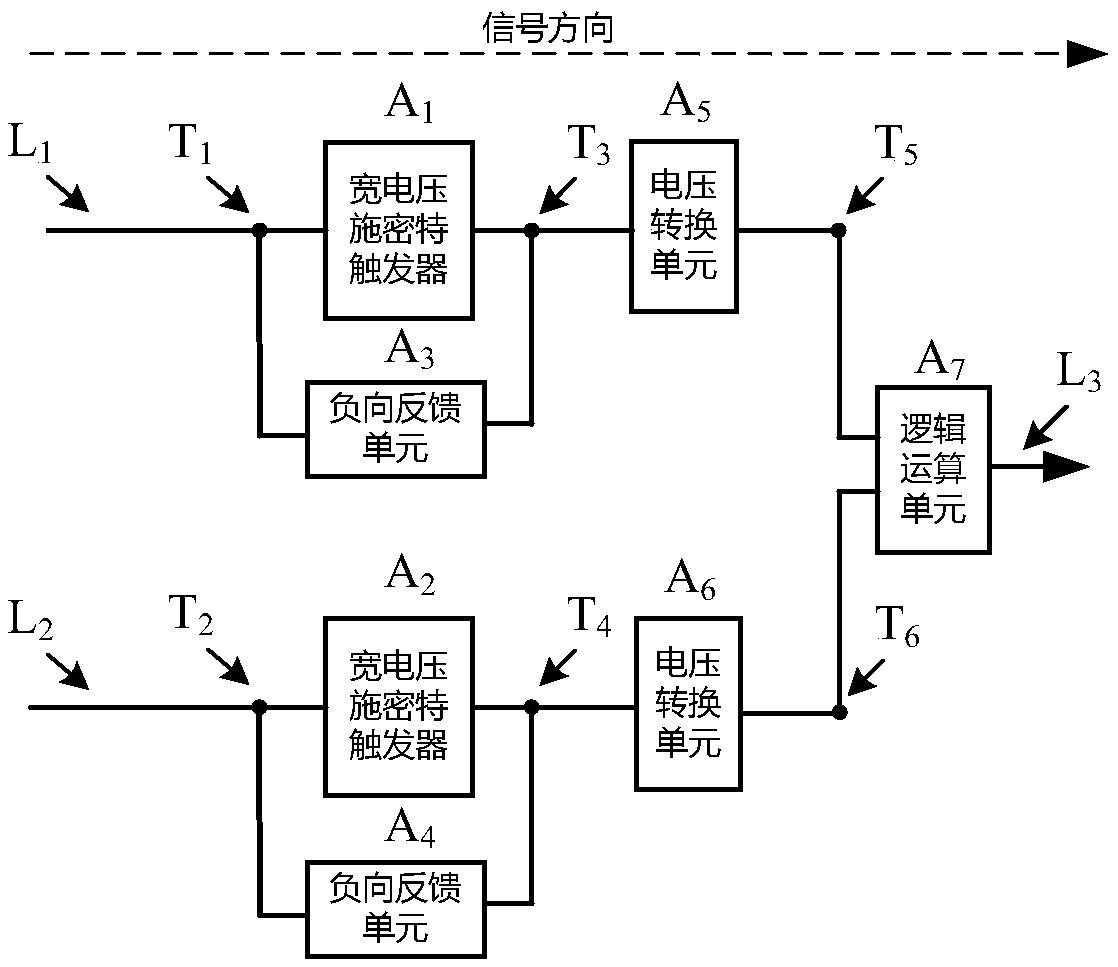

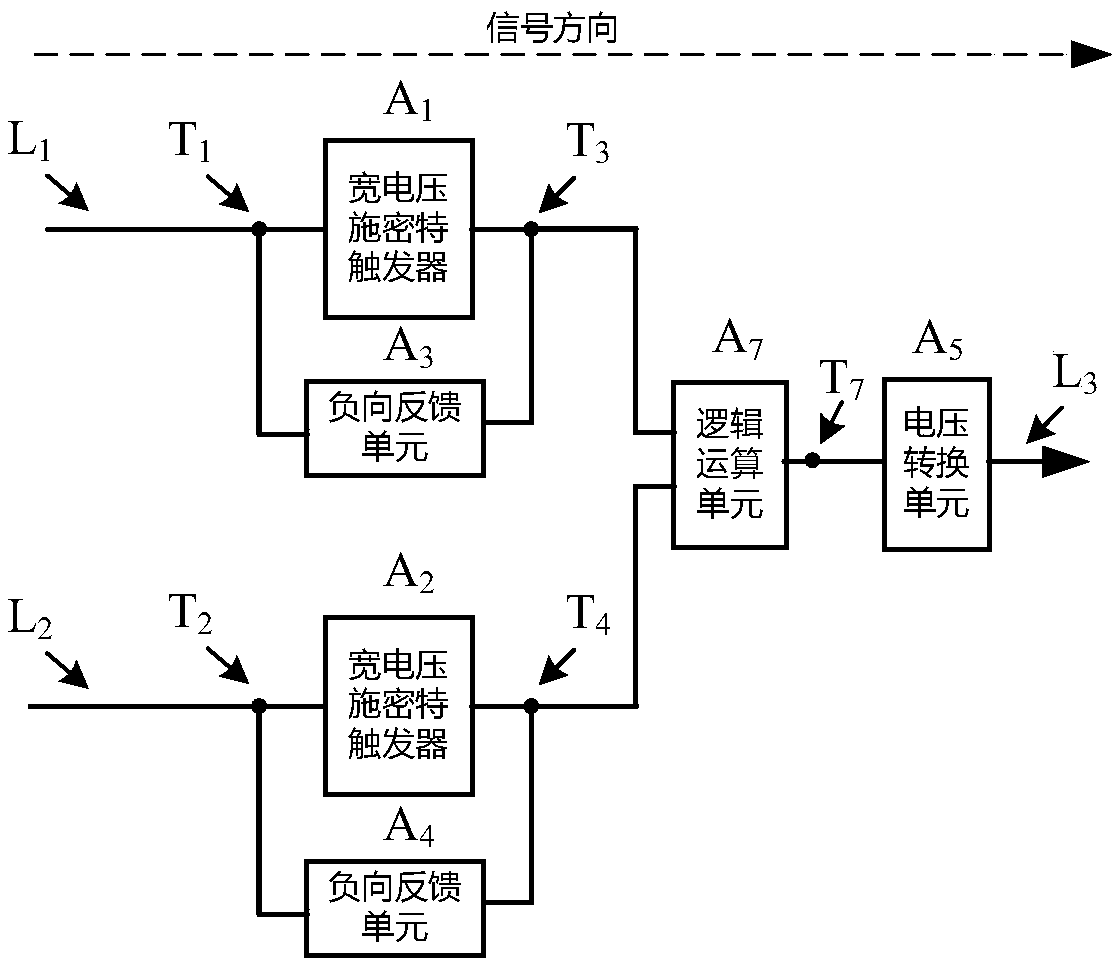

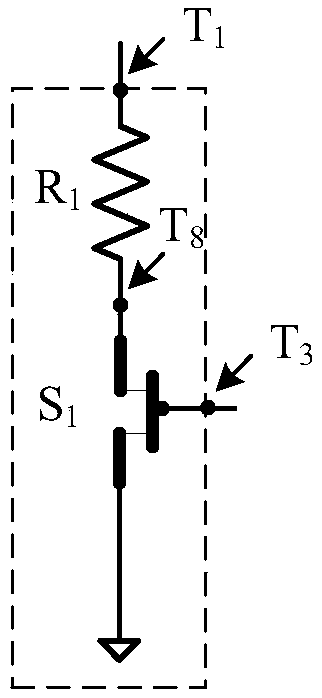

[0022] An electronic detonator signal receiving circuit, which includes a logic operation unit and two signal receiving paths, the logic operation unit has two input ends and an output end, the two signal receiving paths and the two signal receiving paths of the logic operation unit The input terminals are connected one by one, and each signal receiving path includes a Schmitt trigger with a working voltage of 2.5V to 24V and a voltage conversion unit for converting the input level signal into a standard level signal output, The standard l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com