3DTEM and 3DAP multi-scale characterization universal sample table

A sample stage and cross-scale technology, applied in the field of nanomaterials, can solve the problems of lack of accurate element composition and distribution information, difficulty in obtaining defect and crystallographic information, and inability to provide composition information, etc., to achieve convenient operation, easy disassembly, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0022] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

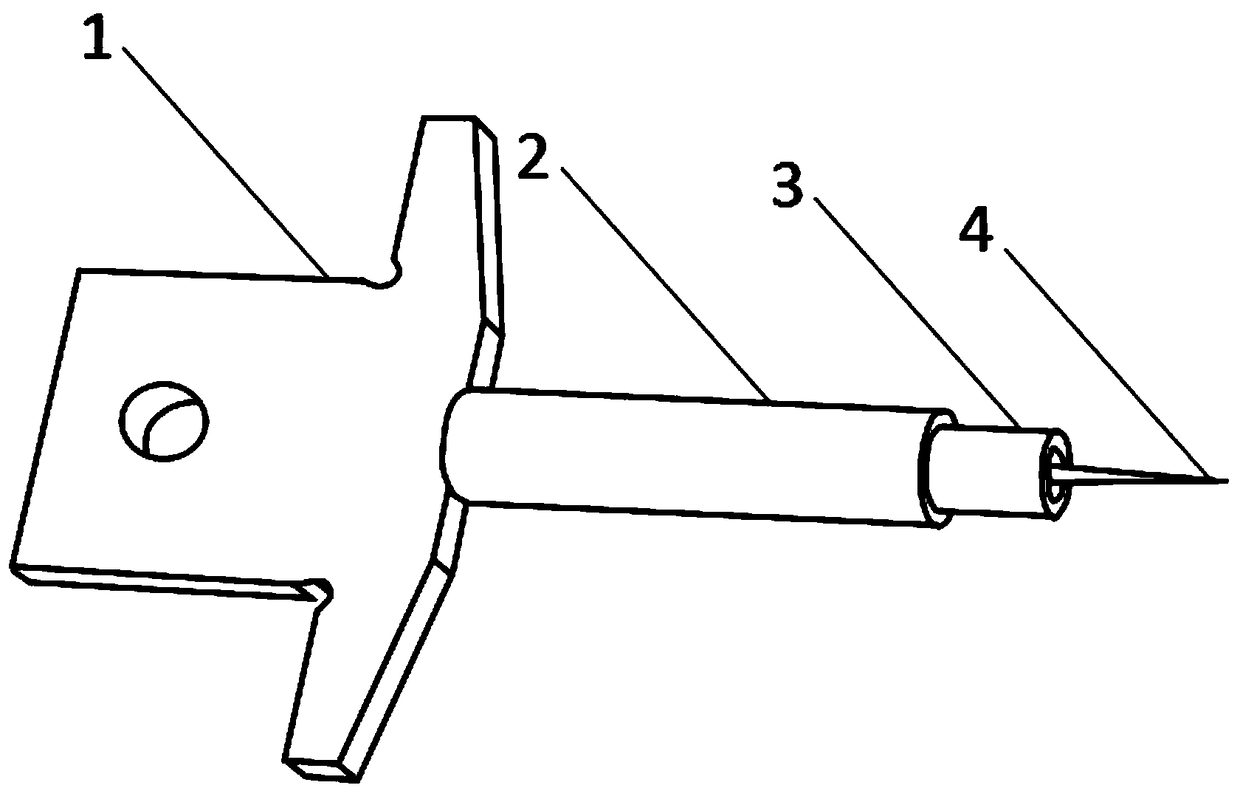

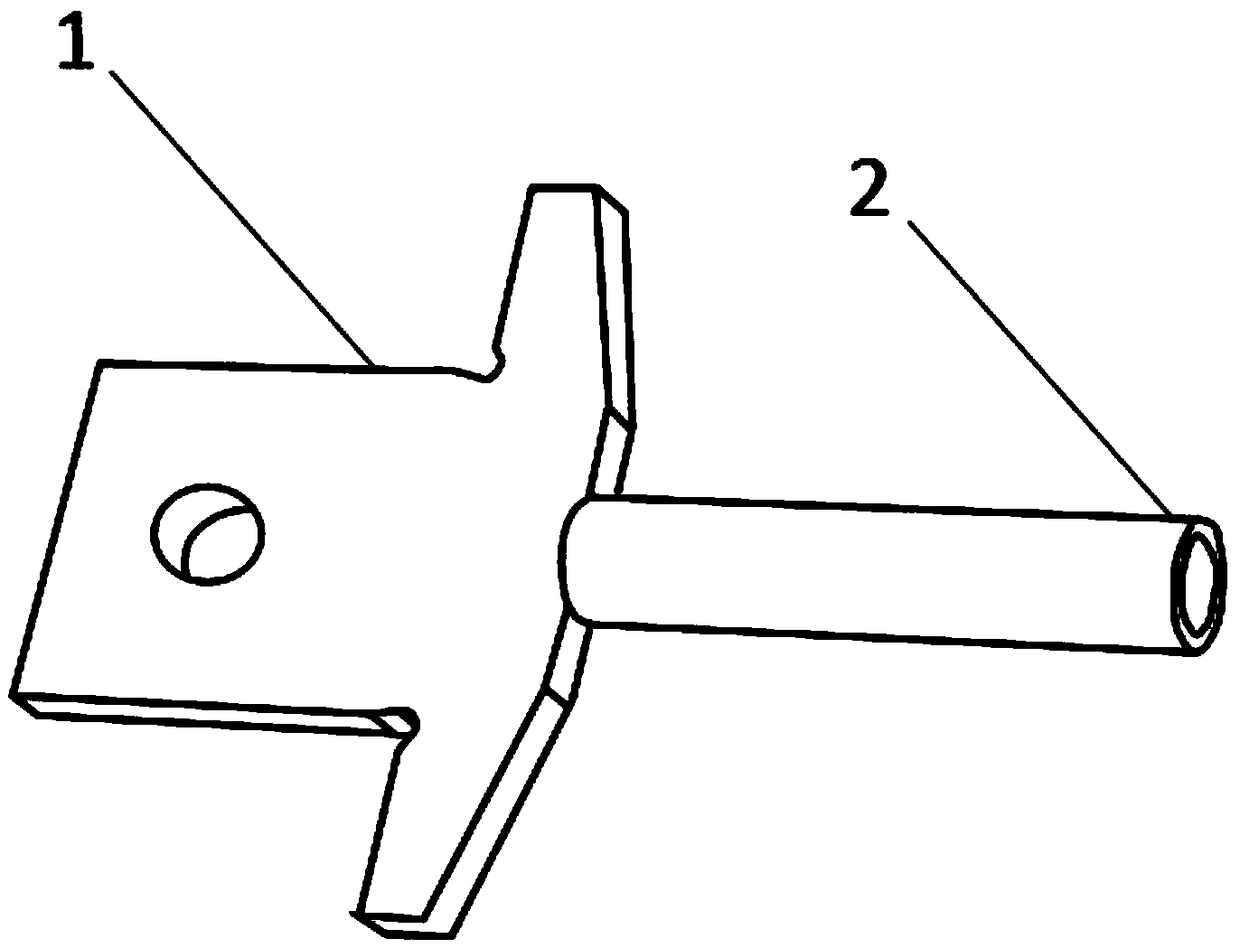

[0023] Such as figure 1 and figure 2 As shown, the universal sample stage for 3DTEM and 3DAP cross-scale characterization provided by the embodiment of the present invention includes: a sample stage base 1 , an outer copper tube 2 , an inner copper tube 3 , and a three-dimensional atom probe needle-shaped sample 4 .

[0024] The sample stage base 1 is made of copper, and the end connected with the sample rod is the tail end, which is rectangular. The ends are at right angles, and the connection is chamfered with a certain diameter.

[0025] The outer copper tube 2 is welded together with the sample stage base 1 by argon arc weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com