Reformer including extrusion guide walls perpendicular to the flow path

A technology for guiding walls and paths, applied in the manufacture of circuits, electrochemical generators, final products, etc., can solve the problems of limited production method assembly steps, waste of materials, unsuitable closed structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

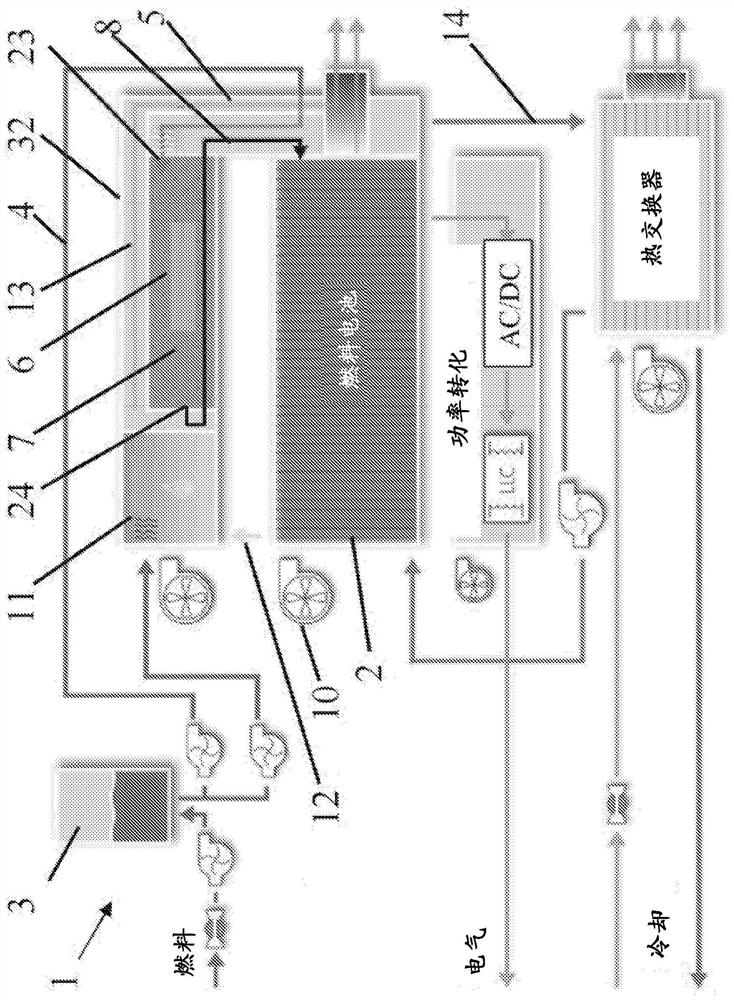

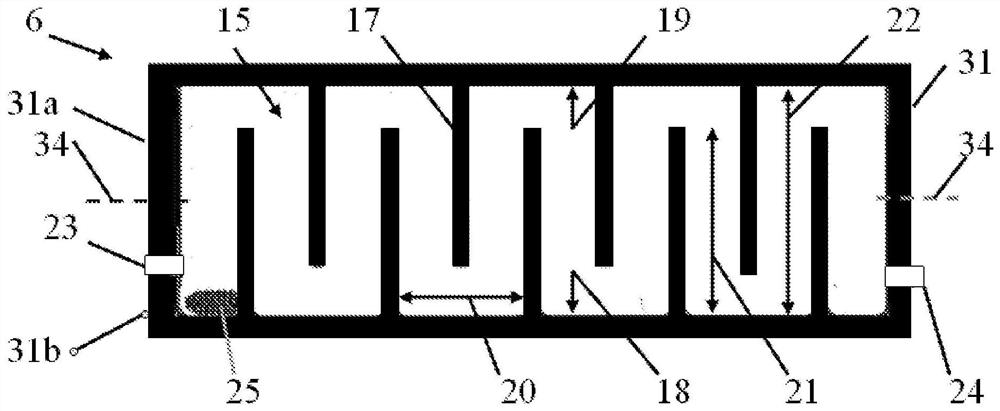

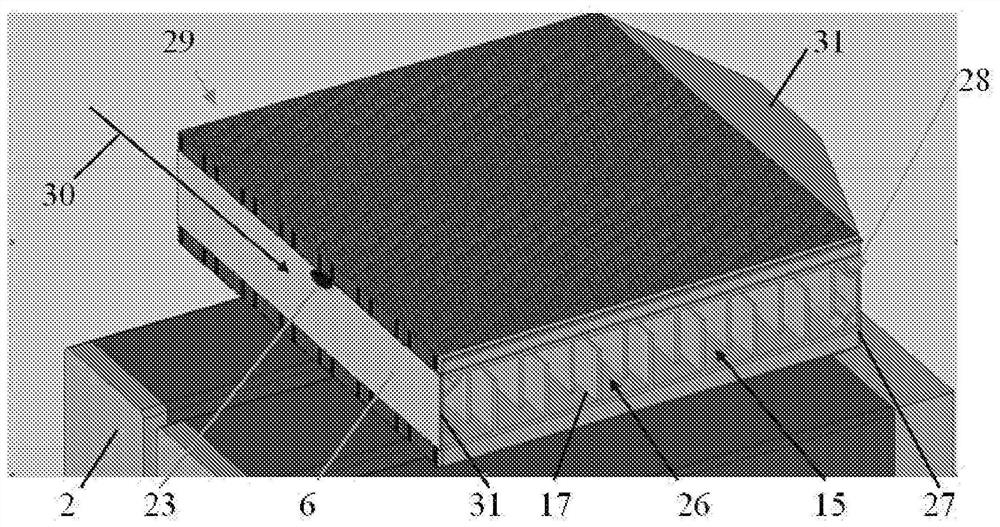

[0035] figure 1 A fuel cell system 1 is disclosed. The fuel cell system 1 includes a fuel cell stack 2 for which liquid fuel (for example, a mixture of methanol and water) is supplied from a fuel supply tank 3 . In the liquid line 4, the liquid fuel is led into an evaporator 5, where the temperature of the liquid fuel is increased until the fuel evaporates. The steam is fed through a steam inlet 23 into a reformer 6 which catalytically converts the steam into synthesis gas, for example by using a catalyst 7 optionally comprising copper. Syngas is mainly composed of hydrogen and carbon dioxide with small amounts of water mist and carbon monoxide. Syngas is supplied to the fuel cell stack 2 anode side of the PEM through a syngas outlet 24 and a conduit 8 external to the reformer 6 , while oxygen, usually from air, is supplied to the cathode side of the PEM from an air supply 10 .

[0036] In order to reach the temperatures relevant for the reforming process in the reformer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com