Preparation method of composite tow for cigarette

A technology of composite spinning and tow, which is applied in the field of preparation of composite tow for cigarettes, can solve problems such as physical harm, and achieve the effects of increasing rod yield, improving curling and resilience performance, and high practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

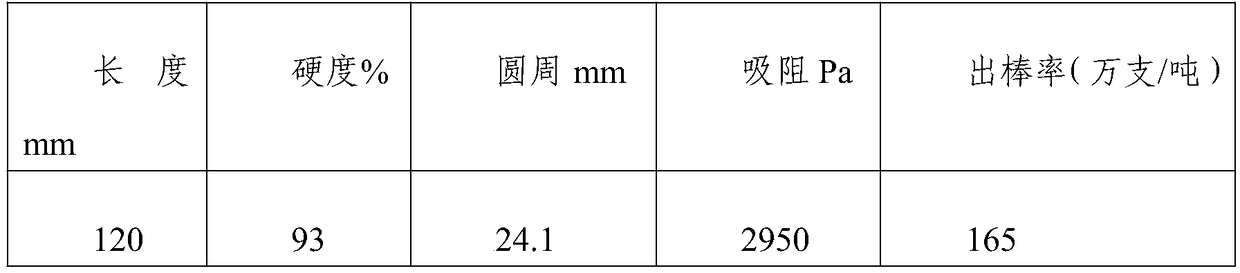

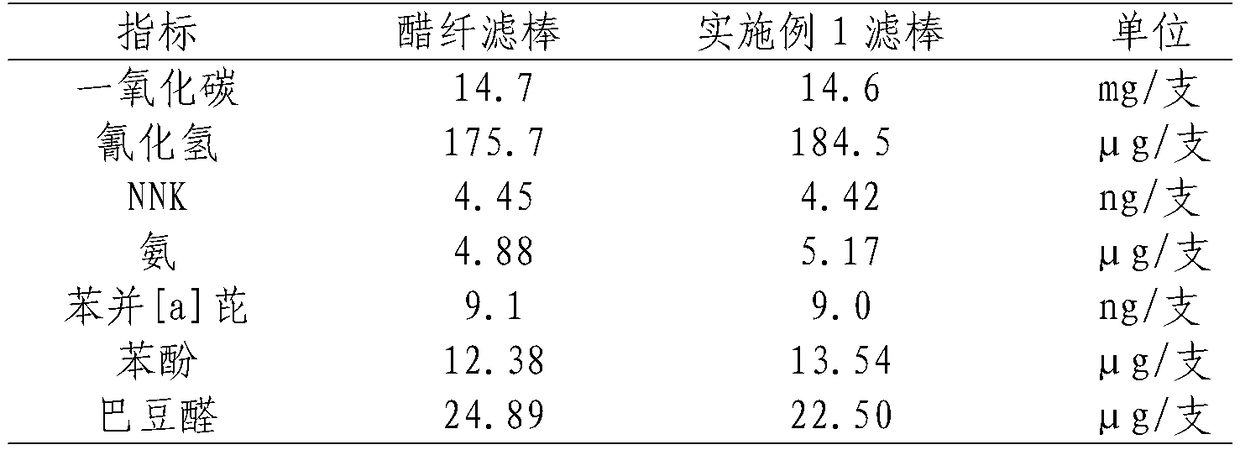

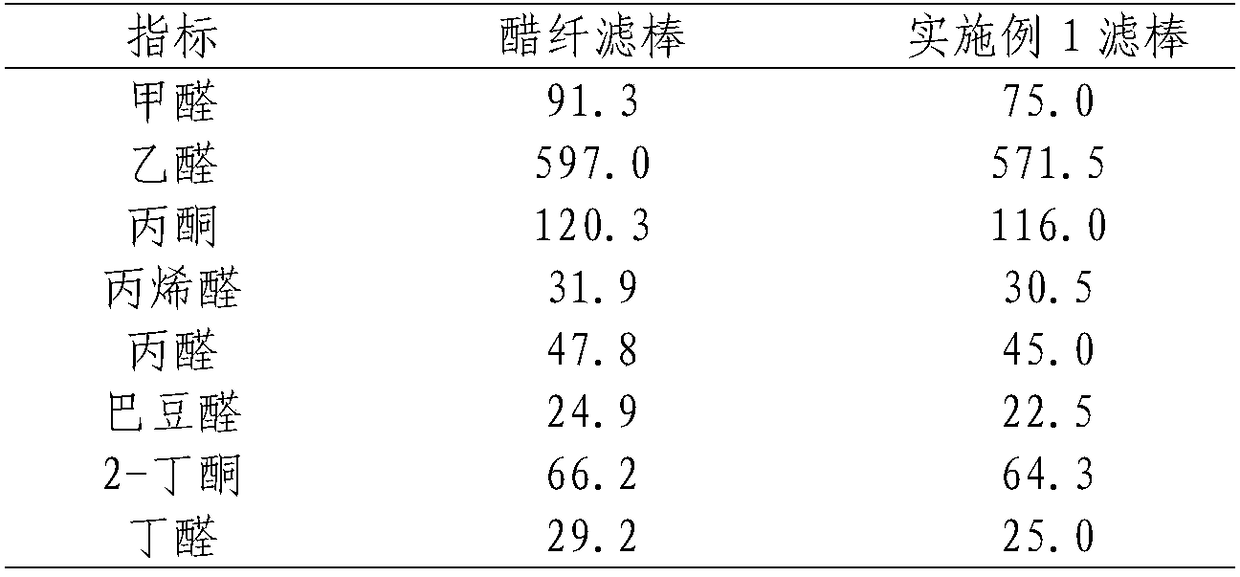

[0037] Example 1: Preparation method of tow

[0038] 1. Raw material slices: component A polyethylene terephthalate PET, melting point 260℃, component B is polylactic acid PLA with conventional melting point (melting point 170℃); component A accounts for 70%wt of the total.

[0039] 2. The preparation process of tow is:

[0040] 1) Drying and crystallizing: Component B slices are dried and crystallized between 70-110°C (heating rate 5°C / h, the temperature remains unchanged when the temperature reaches 110°C), the time is 15h, and the water content in the polylactic acid is controlled to be less than 50ppm; Component A slices are dried and crystallized between 105-170℃ (heating rate is 10℃ / h, and the temperature remains unchanged when the temperature reaches 170℃), the time is 10h, and the water content is controlled to be less than 50ppm;

[0041] 2) Composite melt spinning: the number of holes in the spinneret is 800; the screw temperature of component A spinning is 280℃, the box tem...

Embodiment 2

[0054] Example 2: Preparation method of tow

[0055] 1. Raw material slices: Component A is high melting point polylactic acid (PLLA and PDLA 1:1 blend, melting point 210°C), and component B is conventional melting point PLA (melting point 160°C); component A accounts for the total The amount of 65%wt.

[0056] 2. The preparation process of tow is:

[0057] 1) Dry crystallization: Component B slices are dried and crystallized between 70-110°C (heating rate is 5°C / h, and the temperature remains unchanged when the temperature reaches 110°C), the time is 8h, and the water content in polylactic acid is controlled to be less than 50ppm; Component A slices are dried and crystallized between 105-160℃ (the heating rate is 10℃ / h, and the temperature remains unchanged when the temperature reaches 160℃), the time is 5h, and the water content is controlled below 50ppm;

[0058] 2) Composite melt spinning: the number of holes in the spinneret is 1200; the screw temperature of component A spinning...

Embodiment 3

[0071] Example 3: Preparation method of tow

[0072] 1. Raw material slices: Component A is high melting point PA6 (melting point 250°C), and component B is conventional melting point polylactic acid PLA (melting point 170°C); component A accounts for 65% wt of the total.

[0073] 2. The preparation process of tow is:

[0074] 1) Drying and crystallization: Component B slices are dried and crystallized at 70-110°C (heating rate is 5°C / h, the temperature remains unchanged when the temperature reaches 110°C) for 12 hours, and the water content in polylactic acid is controlled to be less than 50ppm; A slice is dried and crystallized at 110-150℃ (the heating rate is 10℃ / h, and the temperature remains unchanged when the temperature reaches 150℃), the time is 5h, and the water content is controlled to be less than 50ppm;

[0075] 2) Composite melt spinning: the number of holes in the spinneret is 1500; the screw temperature of component A spinning is 310℃, the box temperature is 308℃, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com