Gluing device occupying small space

A gluing device and space-occupied technology, which is applied in the field of textile pretreatment equipment, can solve the problems of large space occupation, small amount of glue application, and large equipment volume, and achieve small equipment occupation, convenient production and assembly, and good absorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

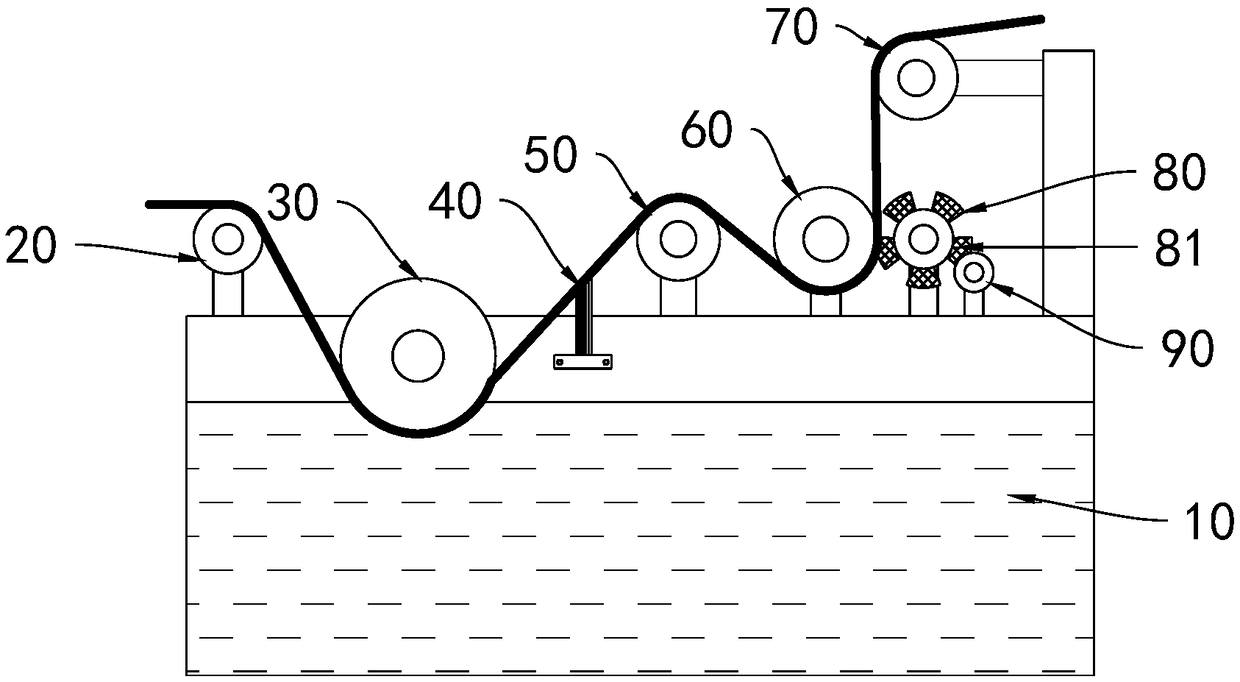

[0018] Embodiment: A gluing device with a small footprint, comprising a box body 10, the upper part of the box body 10 is sequentially provided with a pre-guiding roller 20, a dipping roller 30, a leach brush 40, a steering guide roller 50, Asphalt guide roller 60 and upper guide roller 70, described steering guide roller 50 is arranged on the side of asphalt slurry guide roller 60, and described upper guide roller 70 is arranged on the top of asphalt slurry guide roller 60; 60 is provided with a sponge guide roller 80 and an extruding device 90 in sequential contact with respect to the turning guide roller 50 ; the surface of the sponge guide roller 80 is provided with axially spaced sponge strips 81 .

[0019] The leach brush 40 is in contact with the lower surface of the silk thread, and the bristles of the leach brush 40 are made of plastic material, so as to prevent the easily bifurcated bristles from wearing the silk thread; the direction of the leach guide roller 60 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com