Comprehensive test cooling method for vehicle mufflers

A technology of muffler and cooling work, applied in muffler, engine cooling, coolant flow control, etc., can solve the problems of loud noise, accelerated aging of muffler, reduce the volume of two chambers, etc., to reduce noise , the volume increases, the effect of improving the noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described below in conjunction with the drawings and embodiments:

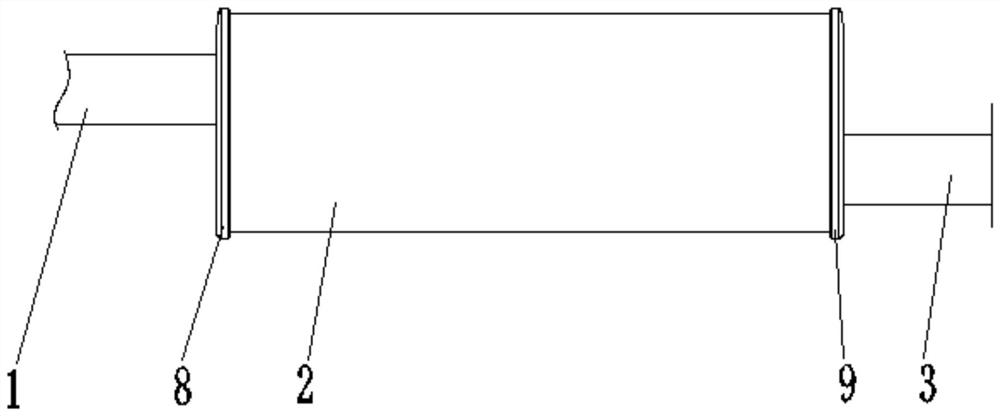

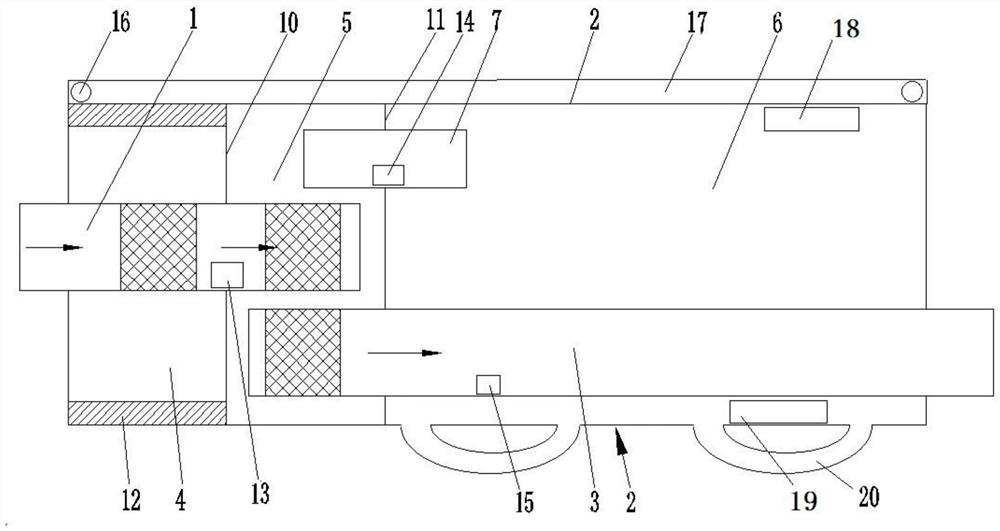

[0034]Such asfigure 1 withfigure 2 As shown, the present invention consists of an intake pipe 1, a cylinder 2, an exhaust pipe 3, a first chamber 4, a second chamber 5, a third chamber 6, a through pipe 7, a front cover 8, a rear cover 9, and a front cover The partition 10 and the rear partition 11 are composed of. Among them, the cylinder 2 is a circular straight cylinder structure. The front end of the cylinder 2 is sealed by the front cover 8 and the rear end is sealed by the back cover 9. Both the front cover 8 and the back cover 9 are preferably circular flat plates, and are welded to the cylinder. Body 2 is fixed. The inside of the cylinder 2 is divided into three chambers by the front partition 10 and the rear partition 11, from the front to the back are the first chamber 4, the second chamber 5 and the third chamber 6, the first chamber 4 The volume of is substantiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com