Lean premixed swirl nozzle of low-pollution combustion chamber and total-ring combustion chamber

A swirling nozzle and combustion chamber technology, applied in the field of gas turbine combustion chambers, can solve the problems of easy flow separation, no prevention of flashback and spontaneous combustion, and large flow loss, so as to reduce the risk of flashback and the generation of nitrogen oxides , the effect of accelerating the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

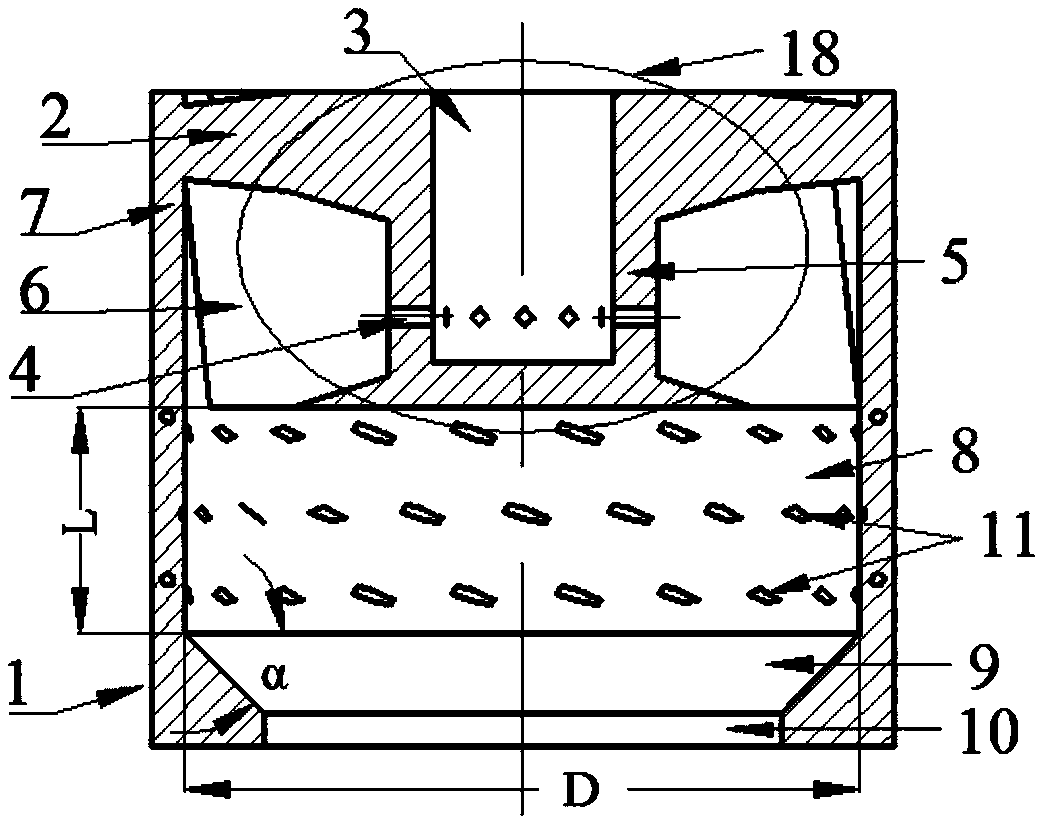

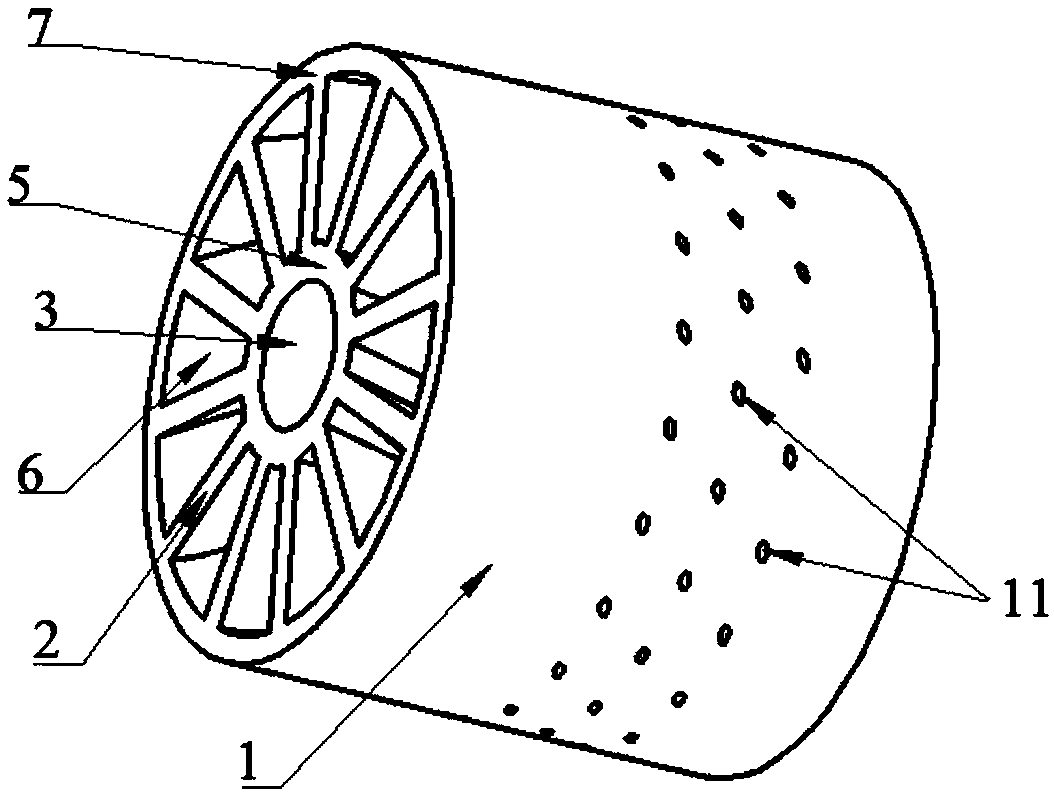

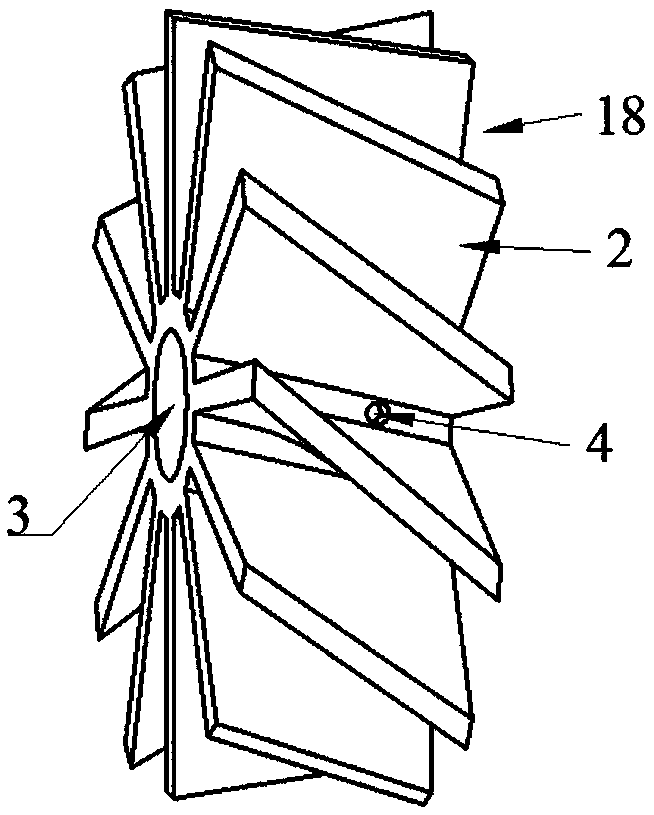

[0037] Such as Figure 1-3As shown, the embodiment of the present invention provides a lean premixed swirl nozzle structure suitable for a low-pollution combustion chamber of a gas turbine, including an axial swirler 2, a fuel inlet 3, a fuel injection hole 4, an inner wall of the swirler 5, Cyclone outer wall 6, swirl flow channel 7, premixing section 8, converging section 9, nozzle outlet 10 and wall divergence small hole 11, said swirl flow channel 7 is composed of axial swirler 2, cyclone inner wall 5 and the swirler outer wall 6, the axial swirler blades 2 are curved blades, the number of blades is 6-20, the blade angle is 30°-60°, and the fuel inlet 3 is located in the swirl channel 7. Inside, the fuel injection holes 4 are opened on the swirler inner wall 5 between the two swirler blades, the injection direction is radially outward, and the number of injection holes is consistent with the number of swirler blades, which is 6-20 , the premixing section 8 is located down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com