Prediction method for temperature distribution and warping deformation in selective laser melting process

A temperature distribution and laser melting technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as inability to accurately measure temperature changes, and inability to predict component warpage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

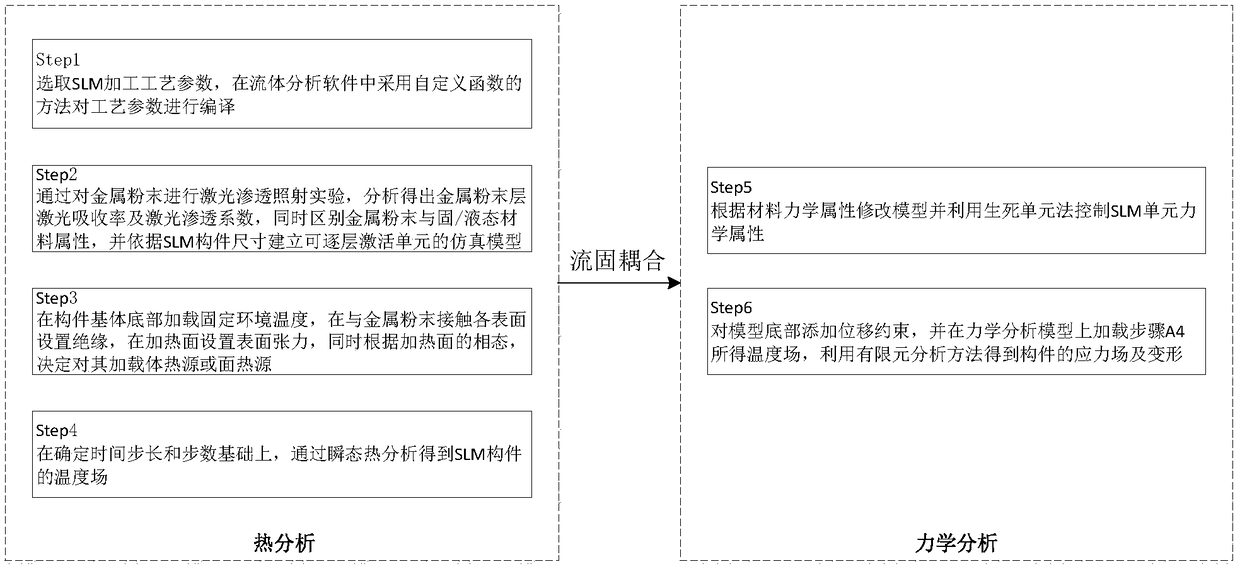

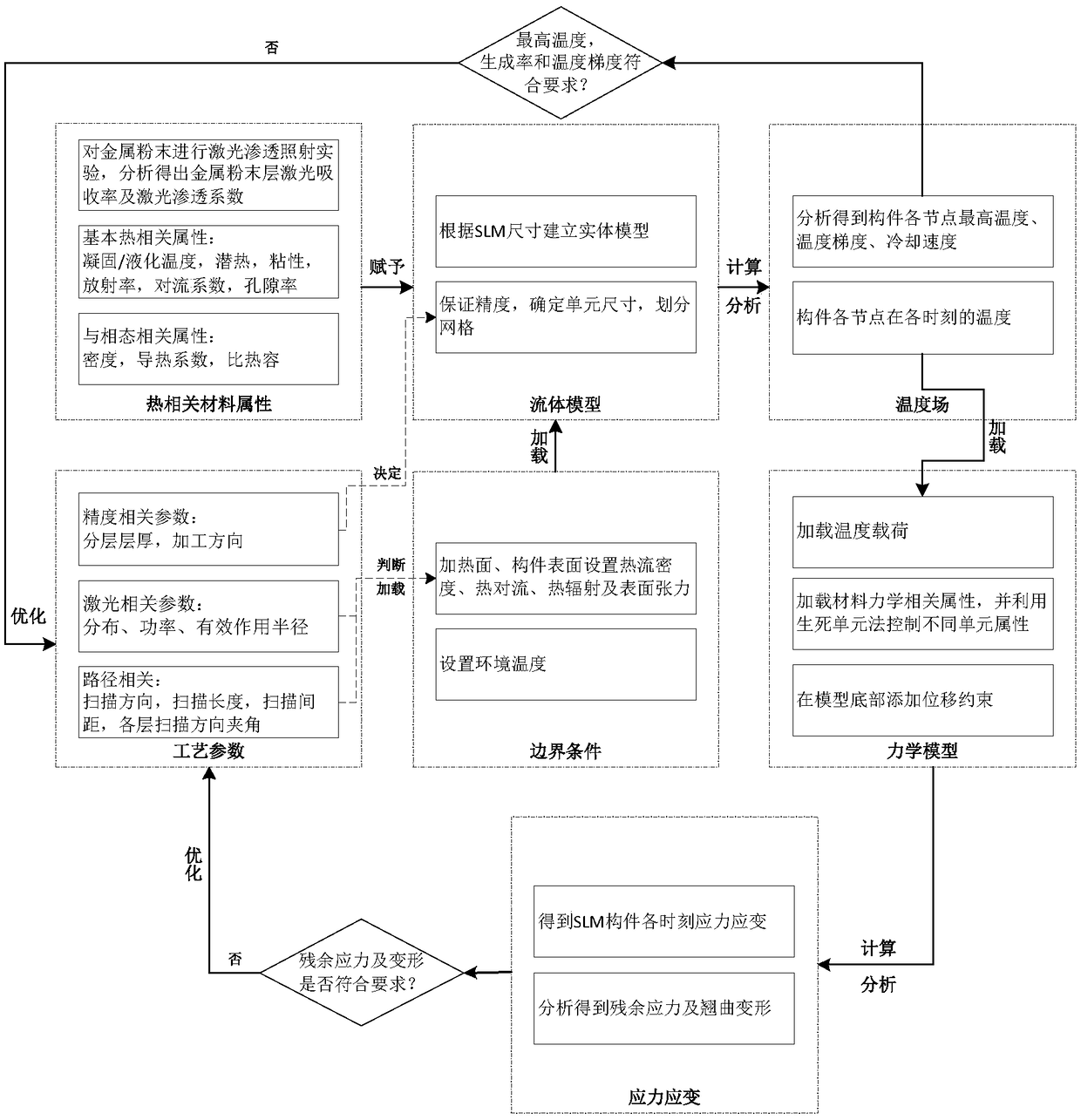

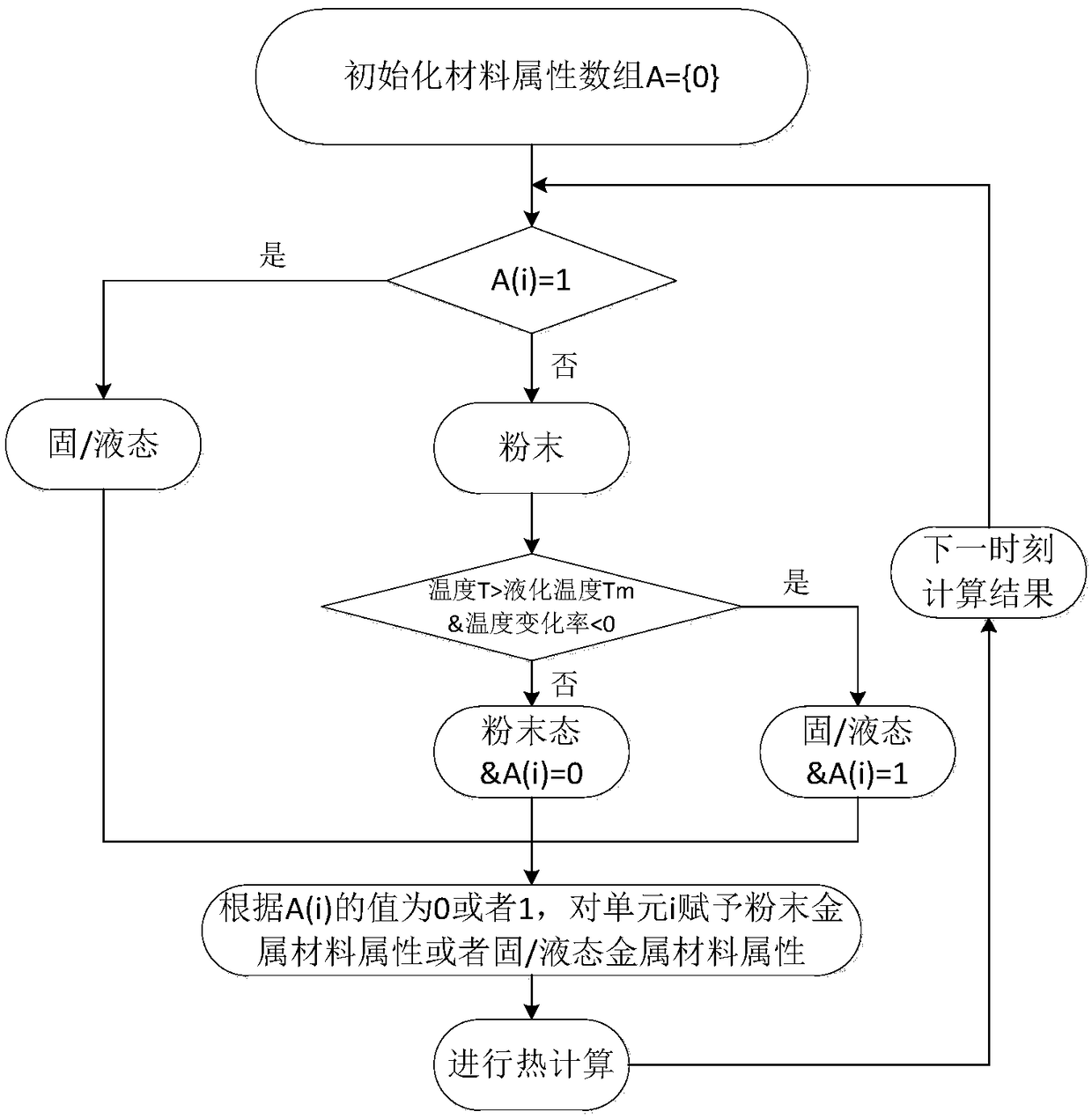

[0030] Such as figure 1 and figure 2 As shown, the present invention designs a temperature distribution and warpage deformation prediction method in the selective laser melting process, which is used to analyze the phase change of metal materials, molten pool forming process, temperature distribution, thermal stress and warpage deformation in the component manufacturing process To analyze and finally predict the temperature distribution and final warpage deformation distribution during component processing, the method mainly includes the following steps:

[0031] Step1, select the SLM processing process parameters, and compile the process parameters in the fluid analysis software by using a self-defined function. In Step 1, the process parameters specifically include: laser type, laser heat source distribution mode, laser power, scanning speed, laser effective radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com