SiC light-activated thyristor with NiO/SiC heterogeneous emitter junction

An emission junction and light-triggered technology, applied in thyristors, electrical components, circuits, etc., can solve the problems of low injection efficiency, large turn-on delay time, high trigger light power, etc., to achieve enhanced hole injection, high hole injection capability, and improved small gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The present invention will be further described in detail below by taking a 10kV 4H-SiC LTT containing a NiO / SiC hetero-emitter junction as an example.

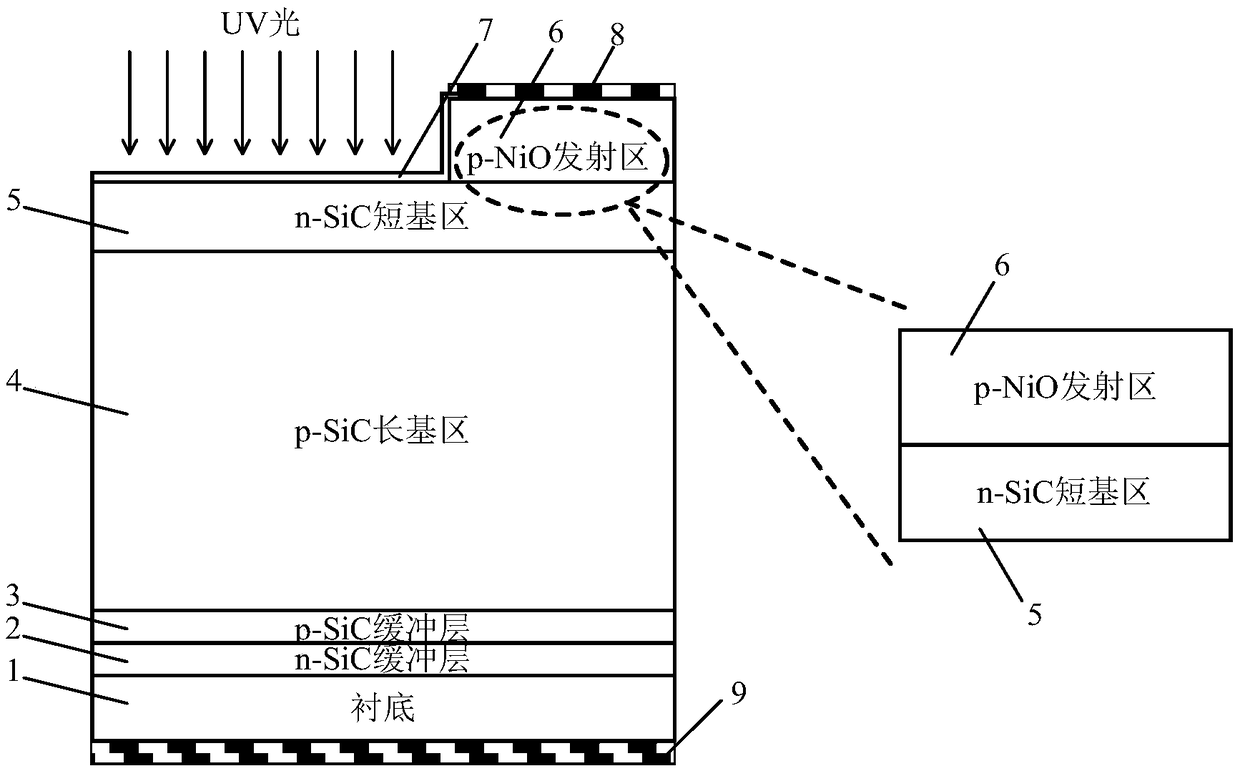

[0040] The main device structure of this embodiment is as follows figure 1 As shown, substrate 1 including 4H-SiC, and n-SiC buffer layer 2, p-SiC buffer layer 3, p-SiC long base region 4, and n-SiC short base region 5 deposited on the upper surface of substrate 1 , the p-NiO emission region 6, the anode 8 positioned on the upper surface of the p-NiO emission region 6, the cathode 9 positioned at the lower end surface of the substrate 1, and the side walls of each boss covered in the p-NiO emission region 6, each boss The insulating dielectric film 7 on the surface of the n-SiC short base region 5 between them.

[0041] The preparation method of the 4H-SiC LTT with NiO / SiC heterogeneous emitter junction in this embodiment is specifically implemented according to the following steps:

[0042] Step 1. Fabricate a subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com