Brushless direct current motor vector control system and construction method thereof

A technology of brush DC motor and vector control, which is applied in the direction of vector control system, control system, motor generator control, etc., and can solve problems such as potential safety hazards, system reliability reduction, and development constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

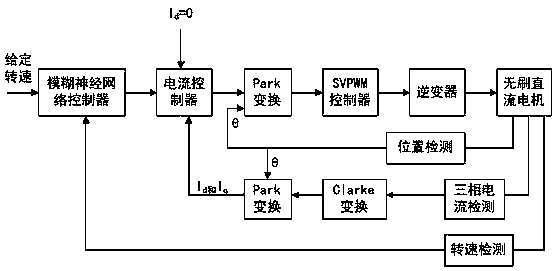

[0108] figure 1 It is the principle block diagram of the brushless DC motor vector control system of the present invention.

[0109] Such as figure 1 As shown, this embodiment 1 provides a brushless DC motor vector control system, including: a dual closed loop regulator, an SVPWM controller and an inverter; wherein the dual closed loop regulator includes a rotational speed adjustment outer loop and a current adjustment inner loop And the rotation speed regulator of the rotation speed adjustment outer loop is suitable for adopting a fuzzy neural network controller; a given rotation speed is adjusted by the double closed-loop regulator and then input to the SVPWM controller; and the SVPWM controller is suitable It generates a control pulse signal and is used as a control signal of the brushless DC motor after being inverted by the inverter.

[0110] Specifically, the brushless DC motor vector control system chooses the dual closed-loop intelligent control design scheme, which is to...

Embodiment 2

[0145] On the basis of embodiment 1, this embodiment 2 provides a construction method of a brushless DC motor vector control system, which includes the following steps:

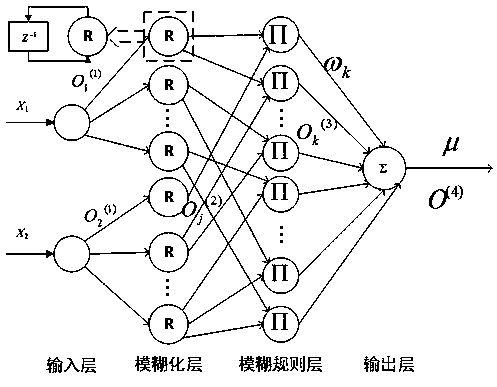

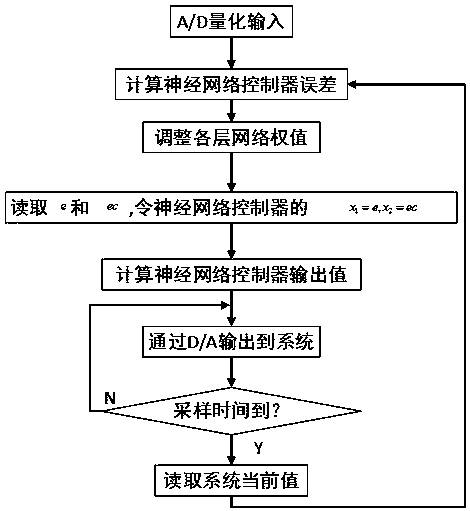

[0146] Step S1, create a fuzzy neural network controller, determine the structure of the fuzzy neural network, and use historical data samples to train and learn the fuzzy neural network to obtain initial values of network weights and thresholds;

[0147] Step S2, optimize the parameters of the fuzzy neural network controller, and use an online supervised learning algorithm to adjust and optimize, so as to improve the dynamic performance of the fuzzy neural network controller;

[0148] Step S3, detecting the three-phase current, rotation speed and rotor position of the brushless DC motor as the feedback value of the vector control system of the brushless DC motor; and

[0149] Step S4, design the motor temperature protection, overcurrent protection, short circuit protection, overvoltage and undervoltage protection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com