A kind of brick tea making method

A production method and brick tea technology, applied in the direction of tea processing before extraction, can solve the problems of low brick surface quality and low degree of automation, and achieve the effects of high production efficiency, high mold precision, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with specific embodiments.

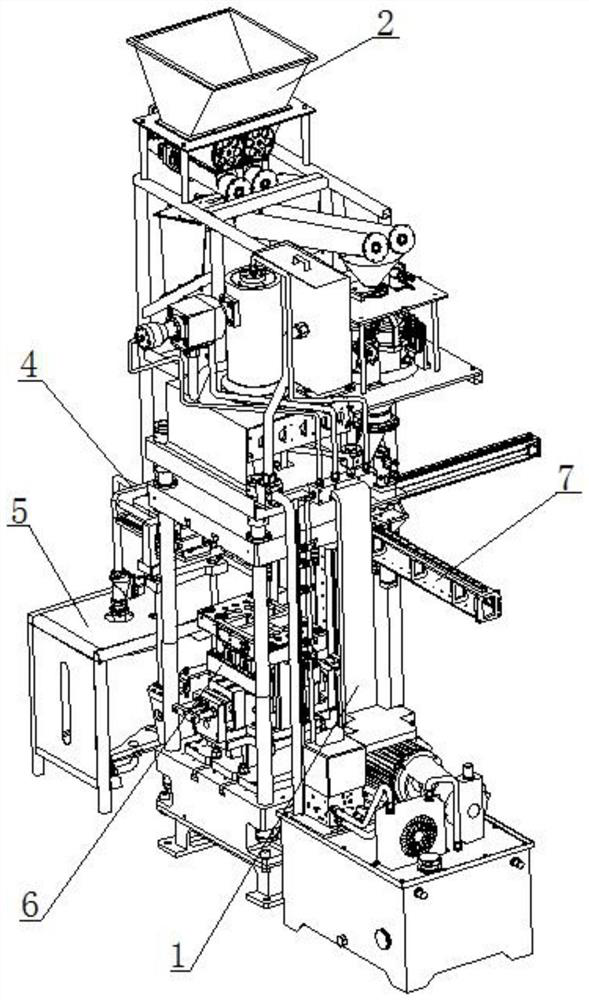

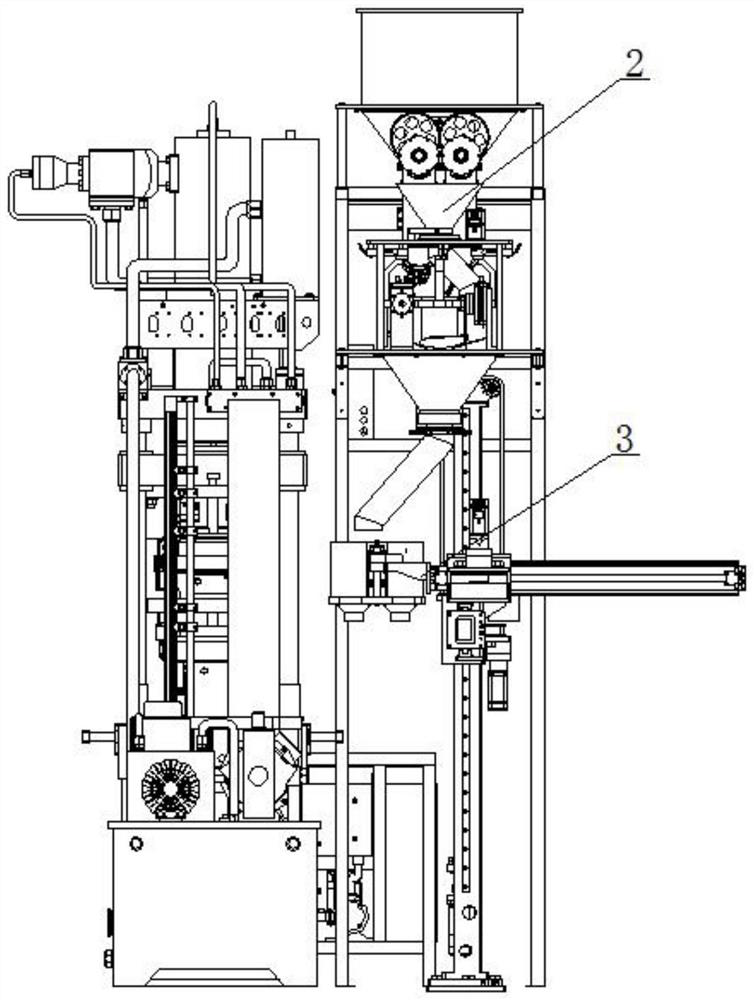

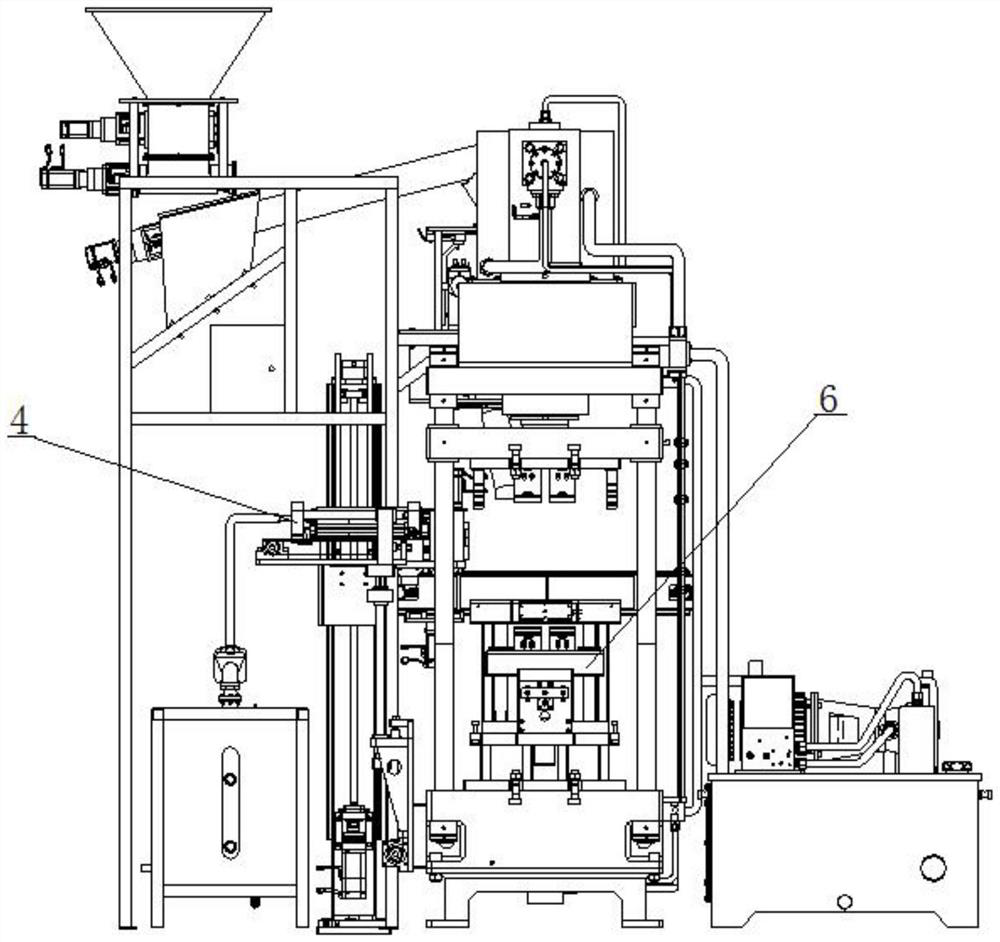

[0053] see Figure 1 to Figure 37 , a method for making brick tea, wherein the brick tea making equipment is used in conjunction with a hydraulic press 1, including a weighing device 2, a homogenizing device 3, a steam generating and heating steaming device, a brick tea mold 6, a manipulator device 7 and a control box. The outlet of the weighing device 2 corresponds to the entrance of the leveling device 3, the manipulator device 7 is connected with the leveling device 3, and the steam generation and heating steaming device is matched with the brick tea mold 6; Hydraulic press 1, weighing device 2, material leveling device 3, steam generating and heating steaming device, brick tea mold 6 and manipulator equipment 7 are respectively connected with the control box.

[0054] see Figure 6 to Figure 13 , the homogenizing device 3 includes a guard plate 8, a main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com