A slow-release multi-layer dental implant and its preparation method and evaluation method

An evaluation method and implant technology, applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of sealing effect, mechanical strength and long-term treatment, food residues, etc. Into the cavity, foreign body sensation in the filling part, etc., to achieve suitable mechanical strength, long-term maintenance of drug effect, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

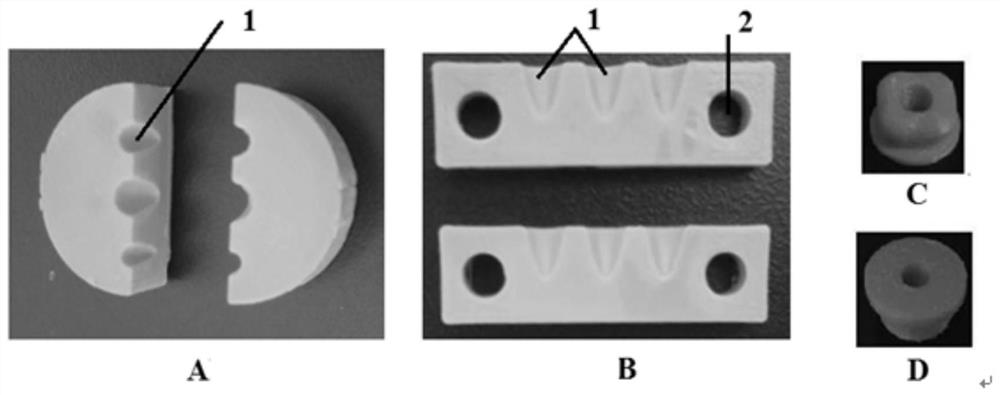

[0038] Embodiment 1 Preparation of mould, release mould, pressurized mould

[0039]3D scanning was used to obtain dental caries information, SolidWorks software was used to design molds, polylactic acid was used as material, and corresponding preparation molds, release molds and compression molds were printed by fused deposition modeling. The nozzle diameter is 0.4mm, the printing temperature is 190°C, the printing speed is 45mm / s, and the layer height is 0.10mm. figure 1 Typical prepared mold, released mold and compressed mold appearances.

Embodiment 2

[0040] Embodiment 2 prepares three-layer implant, and concrete steps are as follows:

[0041] S1: Select the prepared mold B in Example 1.

[0042] S2: 100 parts of ethyl cellulose and 15 parts of triethyl citrate, physically mix, grind evenly, take 80 mg as the first layer material; 10 parts of chlorhexidine, 61 parts of ethyl cellulose, 19 parts of triacetin and 10 parts of HPMC-E5, mixed evenly, hot-melt extruded (90°C, 60rpm, 10min), and 50mg was taken as the second layer of material. 30 parts of chlorhexidine, 60 parts of polyvinyl alcohol and 10 parts of glycerol triacetate were mixed uniformly, hot-melt extruded (85°C, 50 rpm, 10 min), and 50 mg was taken as the third layer material.

[0043] S3: Assemble 1 / 2 of the preparation mold, add the materials of the three layers into the preparation mold respectively for hot pressing (90°C, 5kg, 2min), and divide the 1 / 2 preparation mold to obtain a three-layer implant. look like figure 2 shown.

Embodiment 3

[0044] Embodiment 3 prepares double-layer implant, concrete steps are as follows:

[0045] S1: For different three-dimensional caries models, print different forms of preparation molds.

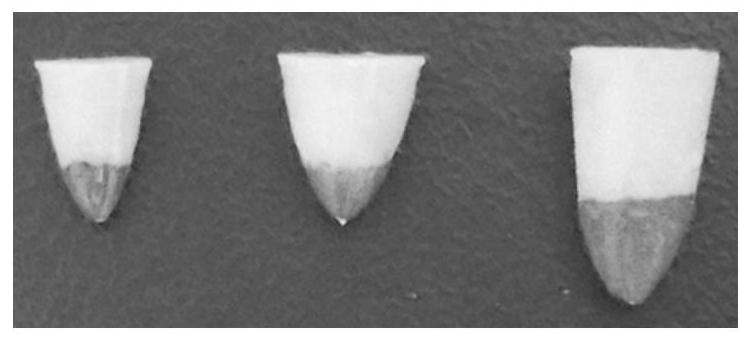

[0046] S2: 100 parts of cellulose acetate and 20 parts of triethyl citrate, physically mix, grind evenly, take 70mg, 90mg and 130mg respectively as the first layer material of 1#-3#; 25 parts of chlorhexidine, cellulose acetate 50 parts, 5 parts of glycerol triacetate and 20 parts of HPMC-E5, mixed evenly, hot-melt extruded (100°C, 60rpm, 10min), 20mg, 30mg and 80mg were taken as the second layer of 1#-3#.

[0047] S3: Combine 1 / 2 of the preparation molds, add the two layers of materials into the preparation molds for hot pressing (80°C, 3kg, 3min), divide 1 / 2 of the preparation molds, and make 1#-3# different shapes and sized bilayer implants that look like image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com