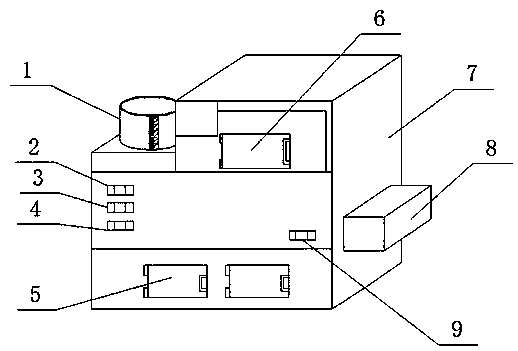

Meat grinder for multi-stage food processing

A technology of food processing and meat grinder, which is applied in the direction of processing meat, meat processing equipment, application, etc., can solve the problems of single function, grading processing, user inconvenience, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

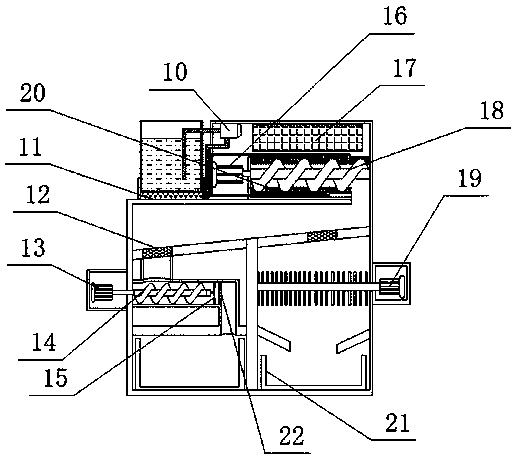

[0023] As a preferred embodiment of the present invention, the suction port of the water pump 10 is connected to the bucket 1 through a water pipe, and the water outlet of the water pump 10 is connected to the inner chamber 2 in the shell 7 through a water pipe.

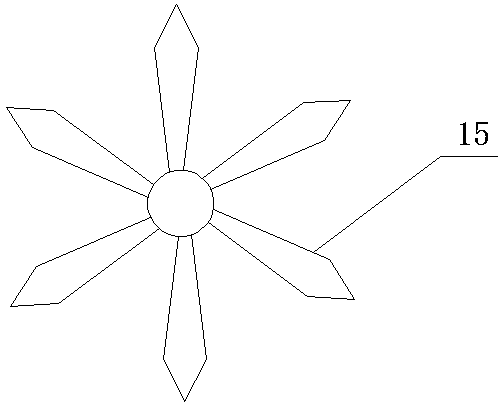

[0024] As a preferred embodiment of the present invention, one end of the screw rod one 14 is welded on the output shaft of the motor, and the other end of the screw rod one is welded with a blade one 15 .

[0025] As a preferred embodiment of the present invention, the bottom of the electric valve 1 is provided with a blade 2 23, and the blade 2 23 is welded to the output shaft of the motor 3 19 through a connecting rod.

[0026] As a preferred embodiment of the present invention, the sterilizing button 2, the meat grinding button 3, the meat cutting button 4 and the feeding button 9 are connected to the storage battery 17 by wires, and the storage battery 17 is connected to the first motor 13, the second motor 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com