Multi-robot precision machining system and method for large-aperture integral optical element

A technology for optical components and precision machining, which is applied in the field of large-caliber integrated multi-robot precision machining systems for optical components. It can solve problems such as high cost and long production cycle, and reduce equipment manufacturing costs, reduce production cycles, and save processing time and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

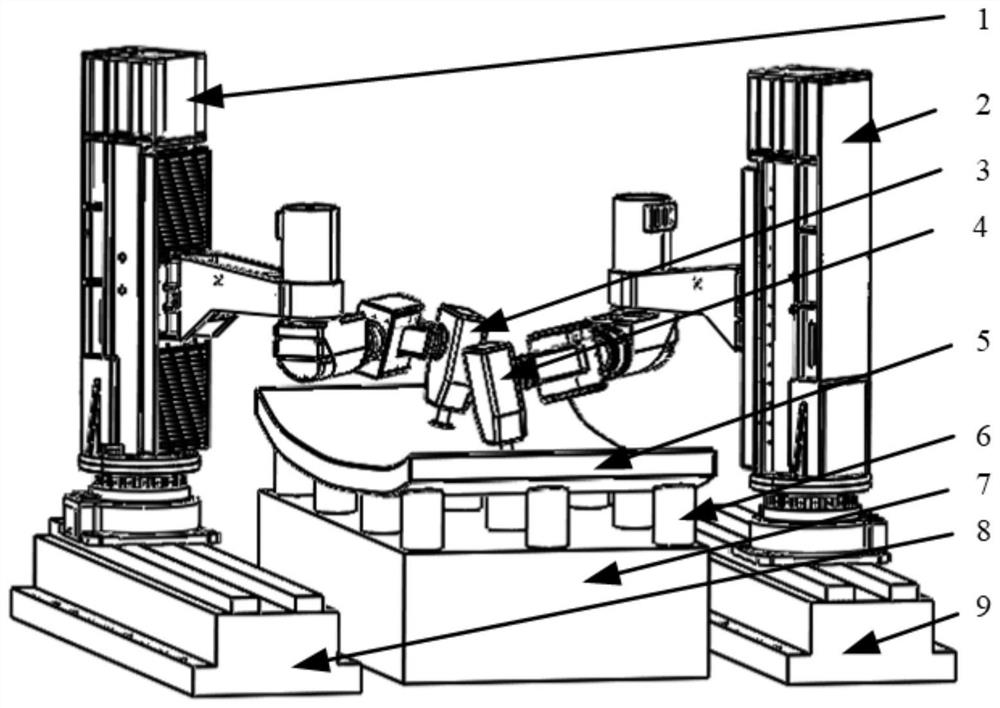

[0067] Specific Embodiment 1: This embodiment is mainly aimed at planar optical elements and optical elements with small curvature.

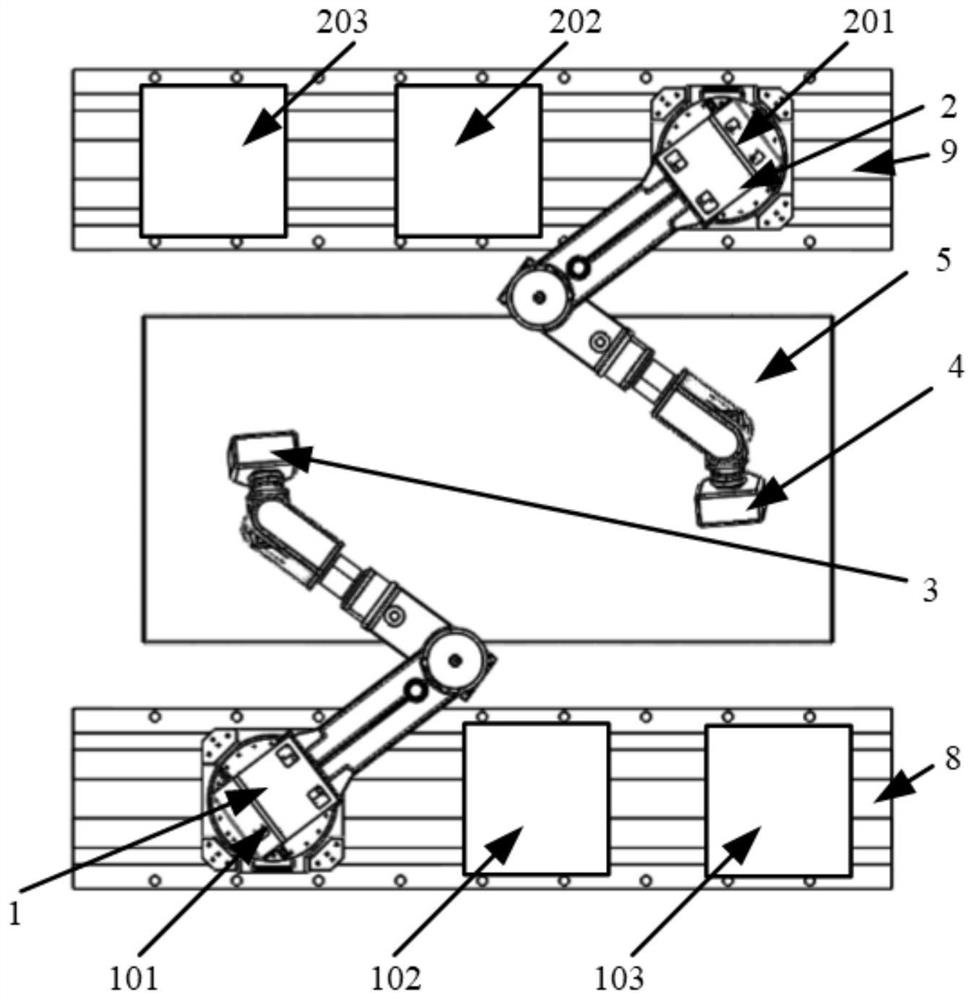

[0068] Firstly, the layout of multiple robots is determined according to the size of the optical element and the processing range of a single robot. The optical element in the specific embodiment 1 can realize the entire optical element 5 by changing the position of the robot on the corresponding slide rail among the two robots. Surface coverage. The first robot 1 and the second robot 2 are symmetrically arranged on both sides of the optical element 5, and a single robot can process half of the optical element. The first robot 1 and the second robot 2 can be positioned on the first robot positioning guide rail 8 and the second robot positioning Slide on the guide rail 9.

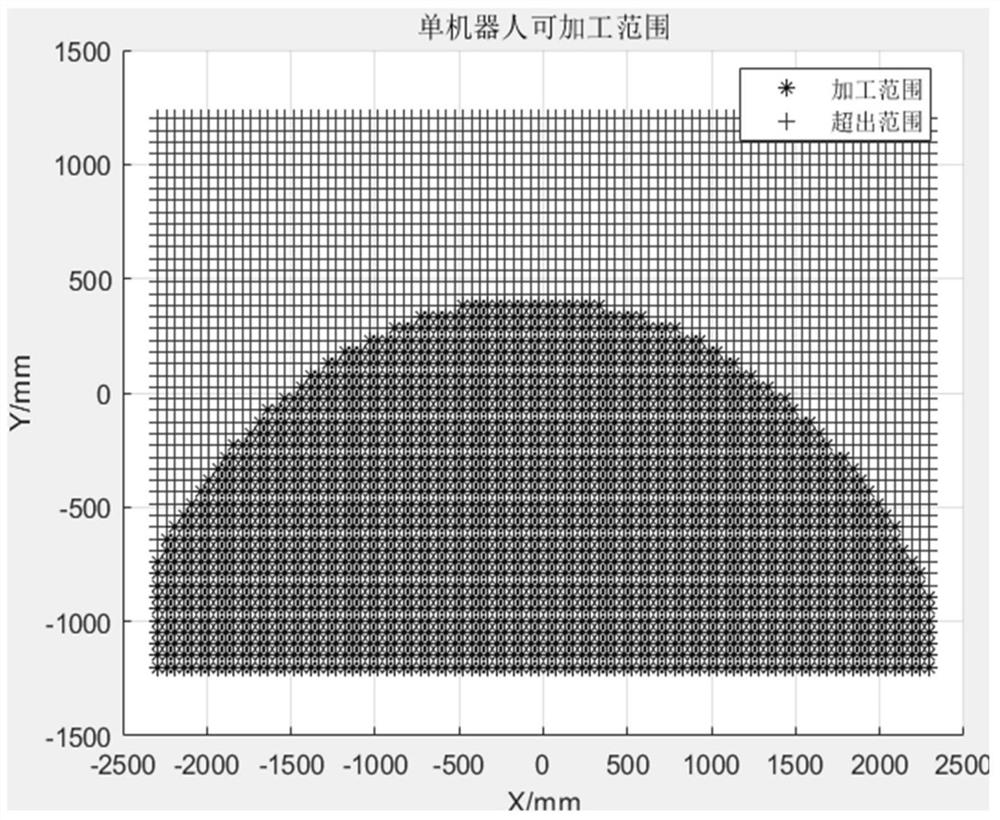

[0069] Further, according to the machinable range of a single robot, calculate and determine the stations required to cover one side of the optical element 5. The double-stat...

specific Embodiment approach 2

[0088] Embodiment 2: This embodiment is mainly aimed at the processing of optical elements with large curvature, and the working mode and processing method of Embodiment 2 are the same as Embodiment 1. Because the curvature of the optical element 5 is relatively large, its grinding process needs to adopt a large curvature grinding part 334. The grinding square of the large curvature grinding part 334 is smaller than the grinding square of the curvature grinding part 335. Under the deformation of the flexible layer 332 of the grinding disc, It can better adapt to large curvature changes on the surface of the element, and has a better fit with the surface of the optical element 5 .

[0089] The used polishing liquid is supplied to the polishing pad 3312 of the recovery tool head module and replaced with a thicker polishing pad, so as to adapt to the curvature change of the large curvature optical element 5 .

[0090] The magnetorheological polishing tool head module used can cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com