Processing method of laser marking machine

A technology of laser marking machine and processing method, applied in typewriter, printing and other directions, can solve the problems of difficult to unify product appearance processing effect, single processing method mode, low processing accuracy, etc., to shorten transition time, flexible processing method, three-dimensional strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing of description:

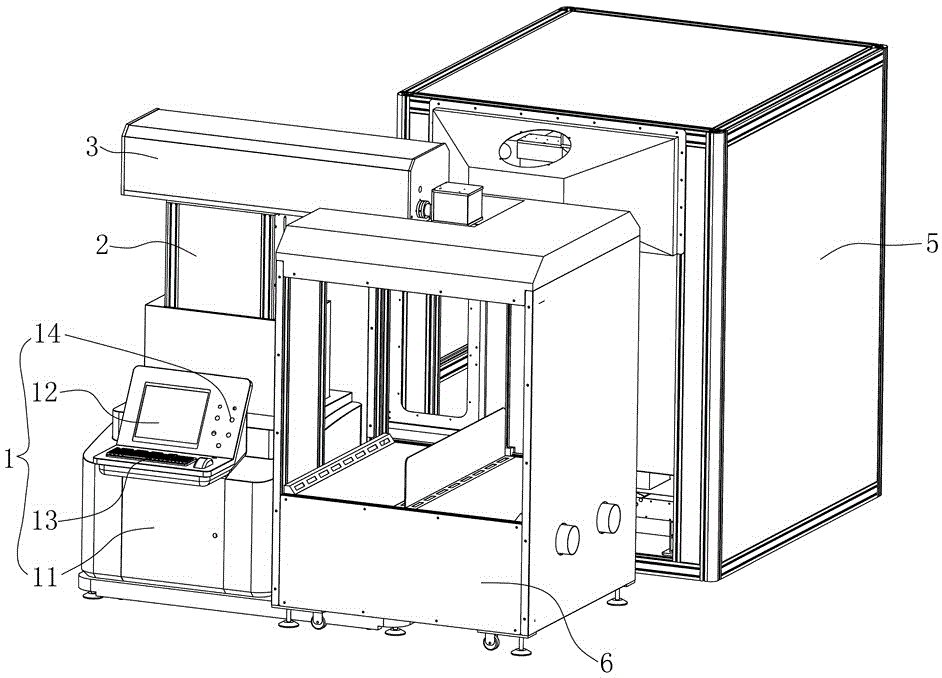

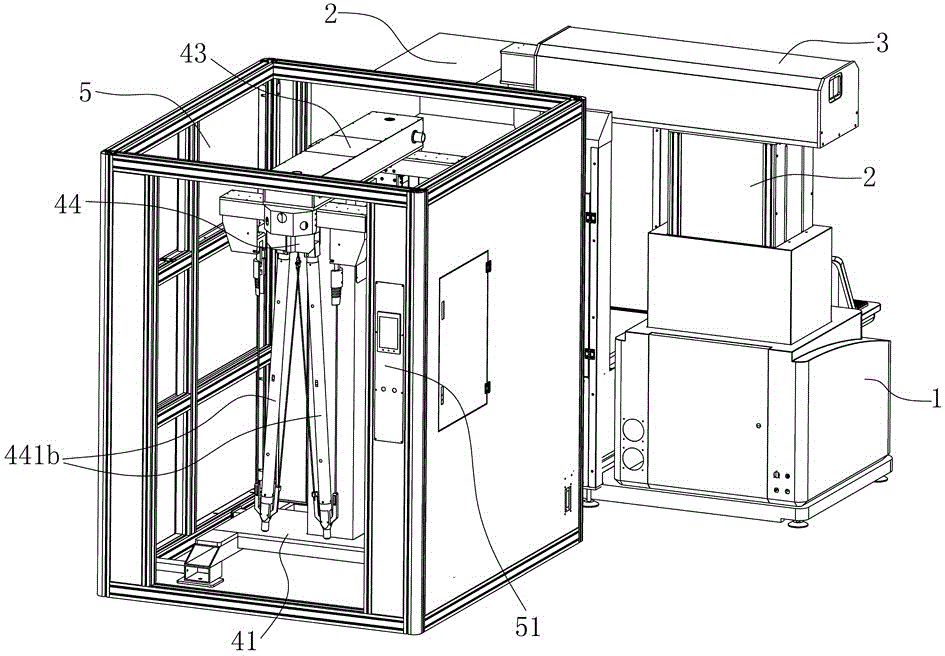

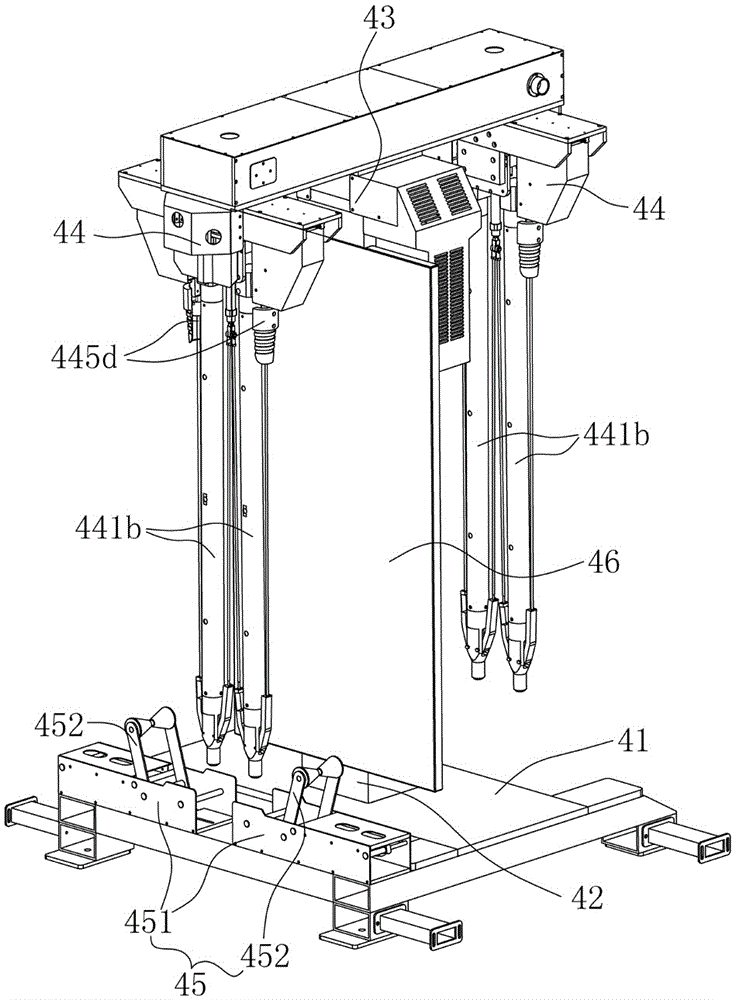

[0031] like Figure 1-8 As shown, the present invention relates to a processing method of a laser marking machine. The laser marking machine is composed of a control unit 1 and an optical path assembly 3 arranged on the control unit 1 through a lift table 2. The rear of one end of the optical path assembly 3 is A 3D vertical support and rotation device 434 is provided, and the 3D vertical support and rotation device 434 includes a base frame 41, a column 42 arranged on the base frame 41, a rotation device 43 located at the top of the column 42, and two sides of the rotation device 43. The support tube device 44 at the end and the expansion mechanism 45 arranged under one of the support tube devices 44, each of the support tube devices 44 includes a support tube part 441, and the 3D vertical support and rotation device 434 is also equipped with a protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com