Automatic product surface treatment process method

A technology of surface treatment and process method, applied in the field of automatic product surface treatment technology, can solve the problem that the fixture cannot achieve the high precision of automation, and achieve the effect of improving the efficiency of surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

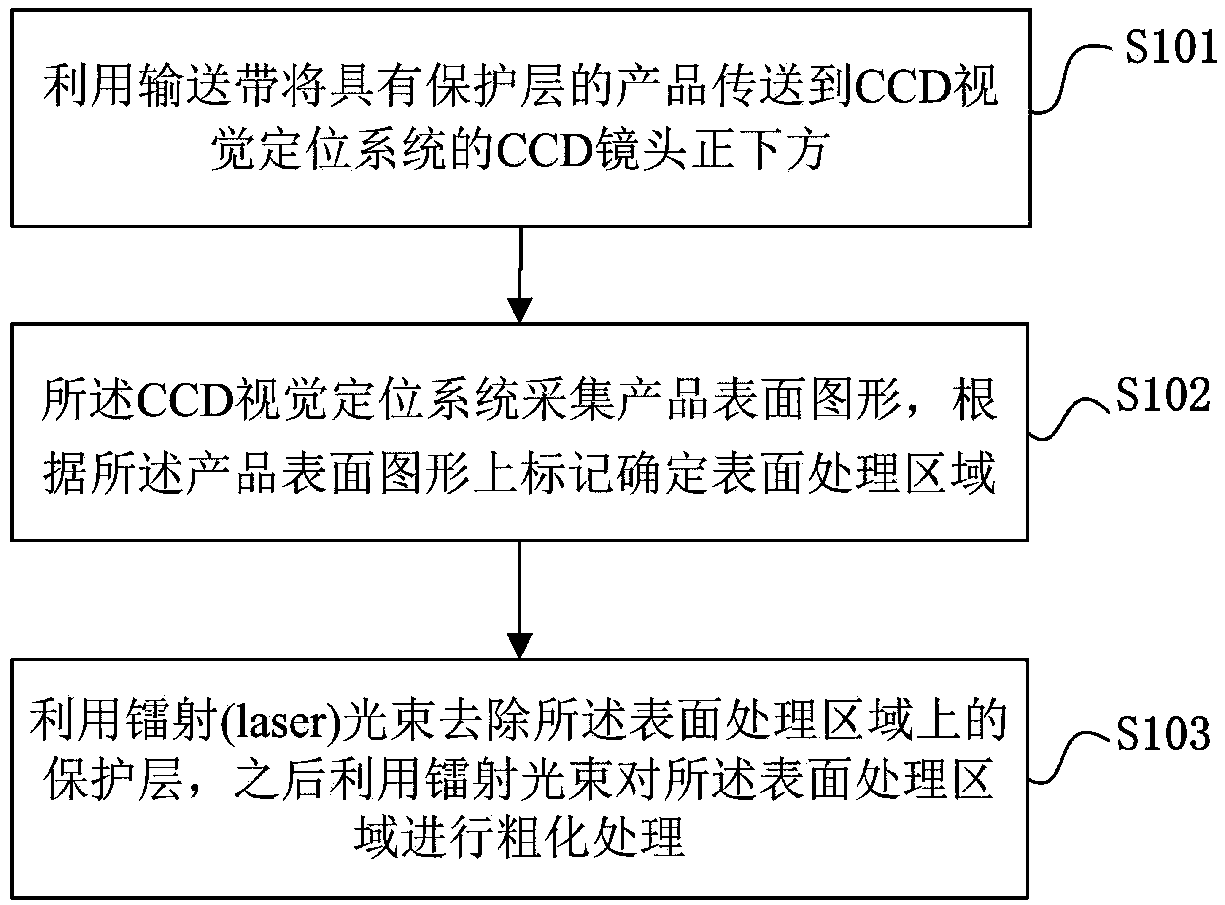

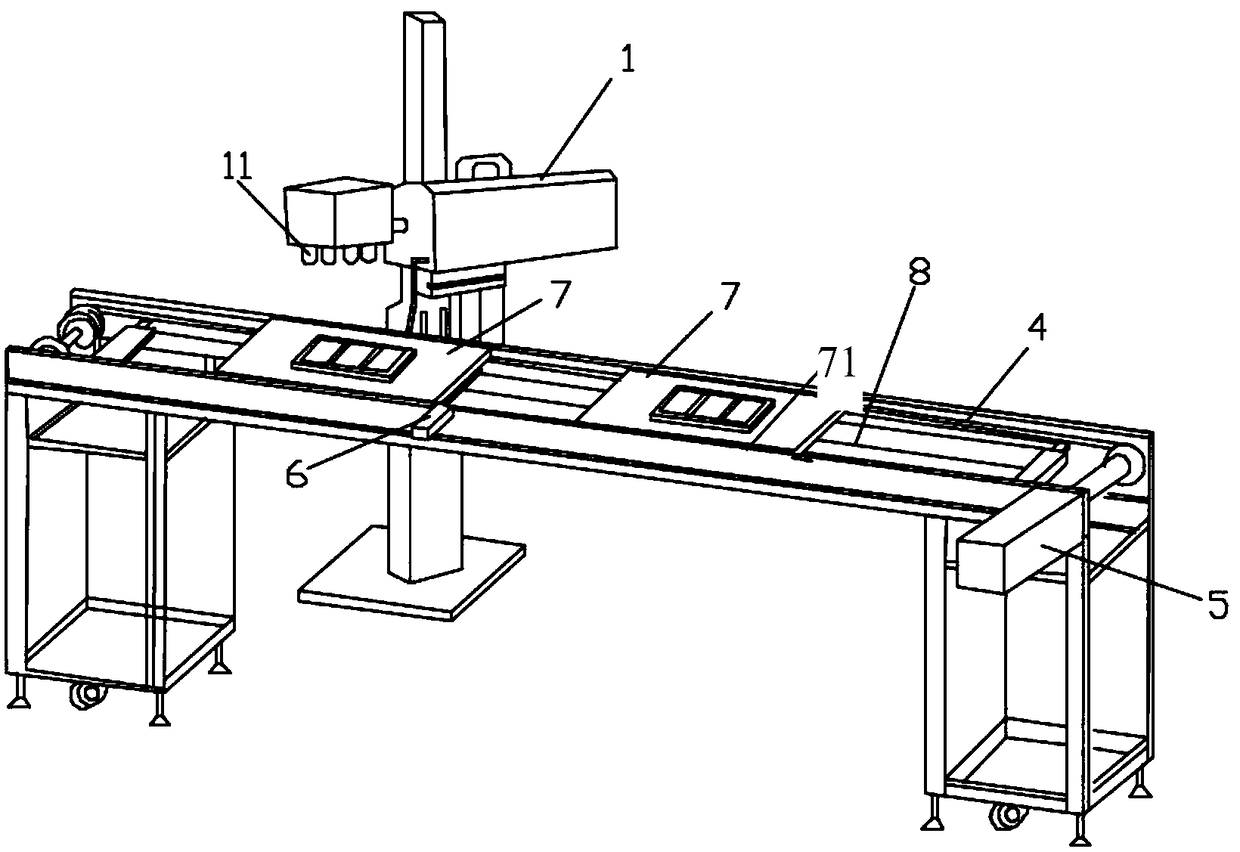

[0038] like figure 1 As shown, the embodiment of the present invention provides a kind of automatic product surface treatment process method, and this method comprises the following steps:

[0039] S101, using the conveyor belt to transmit the product with the protective layer to the directly below the CCD lens of the CCD vision positioning system;

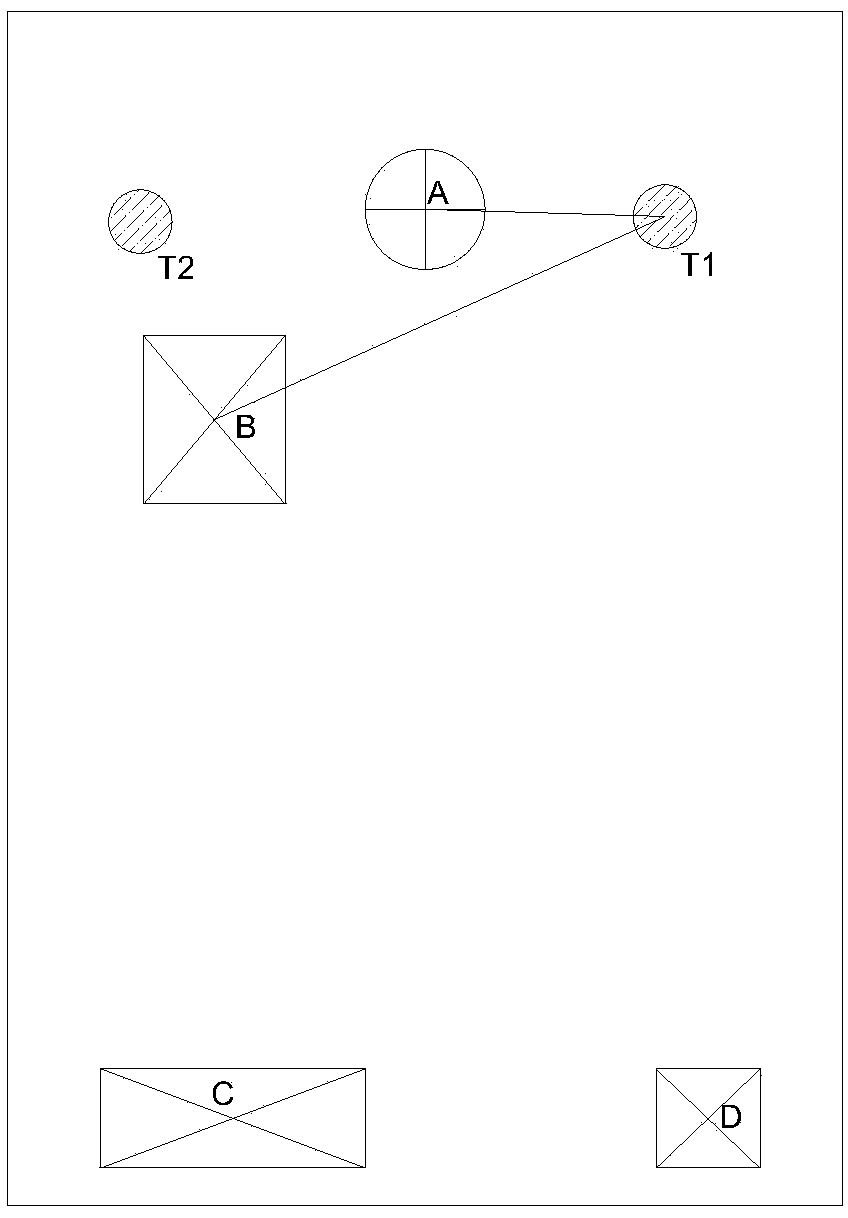

[0040] S102. The CCD visual positioning system collects the product surface image, and determines the surface treatment area according to the mark on the product surface image;

[0041] S103. Using a laser (laser) beam to remove the protective layer on the surface treatment area, and then using a laser beam to roughen the surface treatment area.

[0042] Wherein, before the product with the protective layer is delivered to the CCD vision positioning system directly below the CCD camera lens by using the conveyor belt, the method also includes:

[0043] The product with the protective layer is placed on the transfer table, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com