Fluorinated modified cellulose material and preparation method thereof

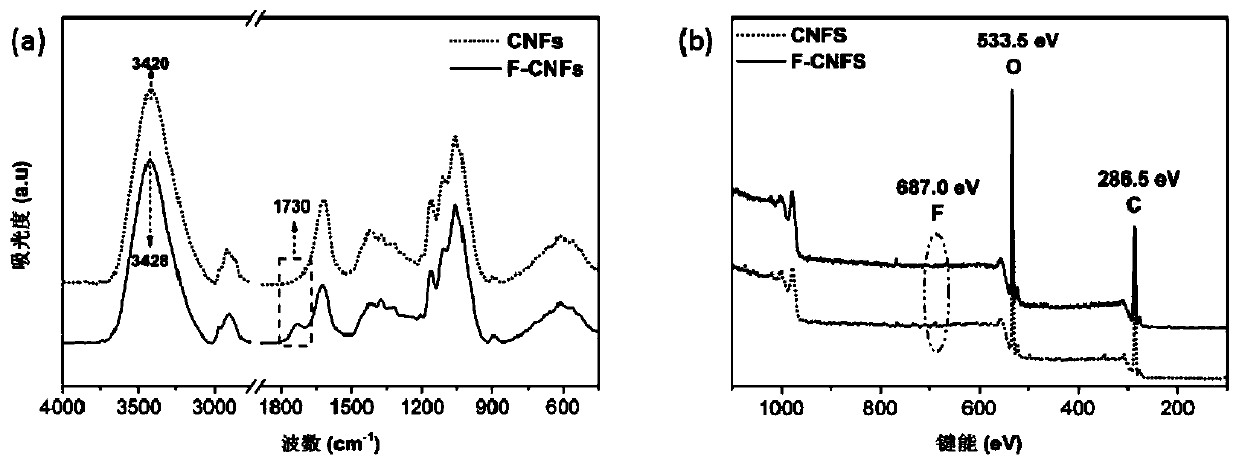

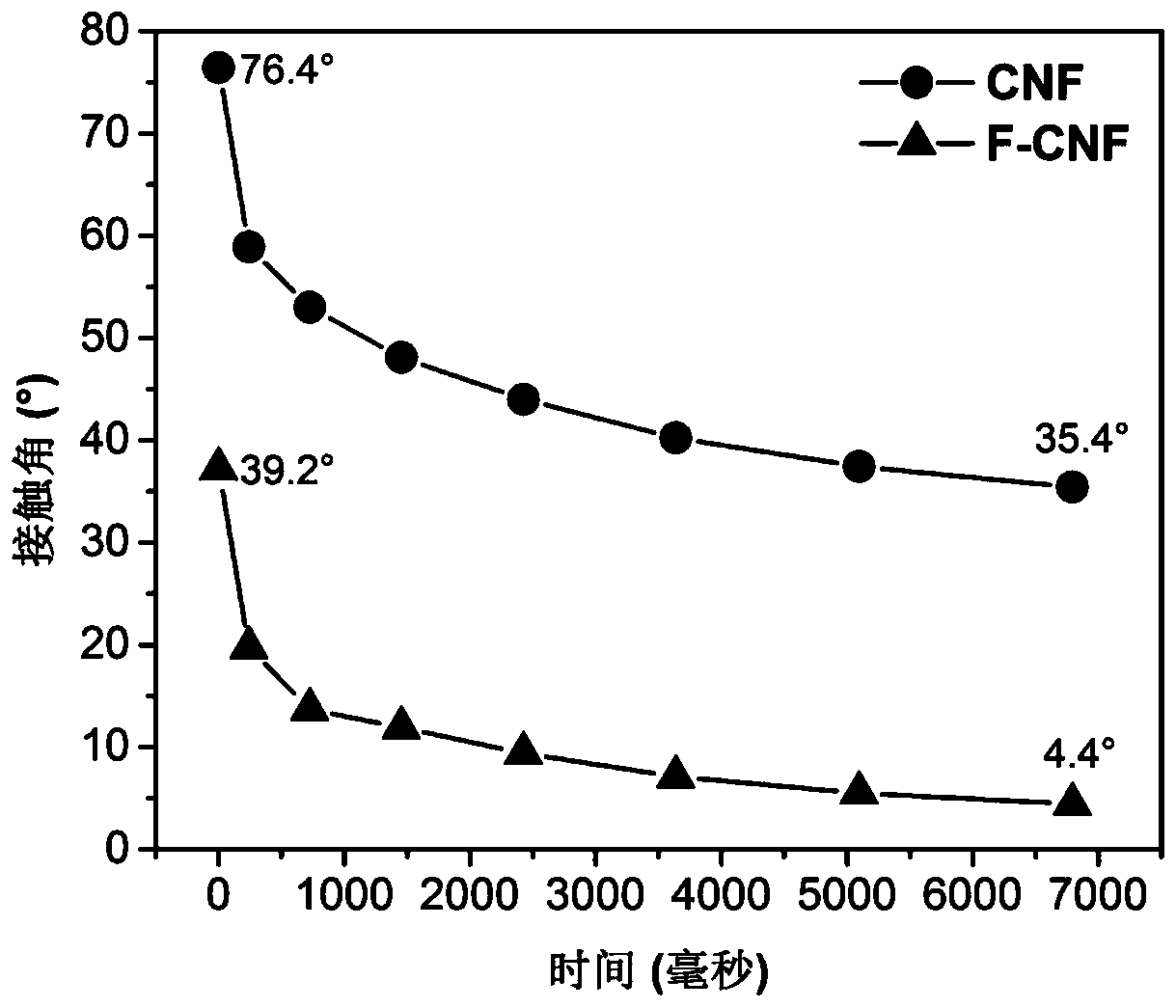

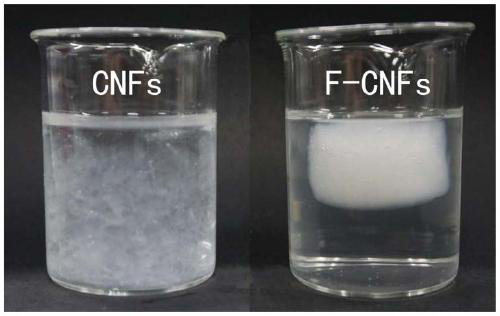

A technology of cellulose and nanocellulose, which is applied in coatings and other directions, can solve the problems of underutilization of nanocellulose, weakening the hydrophilicity of cellulose materials, complicated steps, etc., and achieve good biodegradability and compressive strength Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a fluorinated modified cellulose material, comprising the steps of:

[0027] (1) The reaction vessel is replaced with nitrogen. Before the reaction, nitrogen is introduced into the reaction vessel to prevent the fluorination reaction from being disturbed by other gases, so that the effect of the fluorination reaction is better and the efficiency is higher.

[0028] Optionally, after the replacement, the pressure of the reaction vessel is less than 100 Pa, and the vacuum degree of the reaction is increased, so as to improve the efficiency of the reaction.

[0029] Optionally, the number of times of nitrogen replacement is three times, so that the effect of gas replacement in the reaction vessel is better.

[0030] (2) Feed the mixed gas containing fluorine gas into the reaction container, so that the pressure of the reaction container is 10-100KPa, so that the subsequent fluorination reaction occurs.

[0031] Optionally, the feed rate of the mixed...

Embodiment 1

[0052] The cellulose material is placed in a mixed gas containing fluorine gas and reacted for 40 minutes at a temperature of 20° C. to obtain a fluorinated modified cellulose material.

Embodiment 2

[0054] Put the micron cellulose material into the fluorination reaction kettle, and pass through 10KPaF 2 / N 2 The mixed gas (fluorine gas concentration is 1 vol%) is heated from room temperature to 50° C. at a rate of 1° C. / min and then kept at a temperature of 10 minutes to obtain a fluorinated modified nanocellulose material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com