Ultrasonic-based quick manganese-doped perovskite quantum dot preparation method

A technology of perovskite and quantum dots, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of difficult and rapid cation exchange, prolong the synthesis cycle of fiercely doped perovskite, and achieve low raw material prices , Easy to promote, high fluorescence intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Conventional preparation of Mn:CsPb(Br / Cl) 3 Quantum dots, comprising the steps of:

[0023] 1) Add 1 mmol PbBr 2 , 1 mmol Cs(AC) and 1 mmol MnCl 2 4H 2 Dissolve O in 1ml N, N-dimethylformamide (DMF) and ultrasonically dissolve it completely to make the required precursor solution;

[0024] 2) After mixing 6 ml of oleic acid, 0.8 ml of n-octylamine and 30 ml of n-hexane, add the PbBr obtained in step 1) dropwise in sequence 2 , Cs(AC) precursor solution, stirred for 8-10 minutes, the solution changed from clear to white emulsion, and CsPbBr was prepared 3 Quantum dot materials;

[0025] 3) The MnCl obtained in step 1) 2 Precursor solution was added dropwise to CsPbBr at a rate of 20-60 drops / min 3 In the perovskite quantum dot solution, the reaction is complete in 20-30 hours, and a stable Mn:CsPb(Br / Cl) is prepared 3 Perovskite quantum dots.

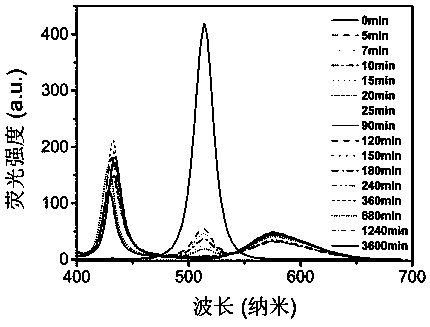

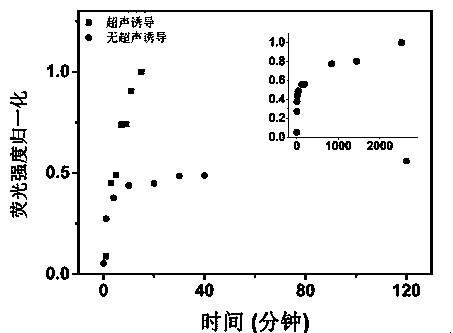

[0026] figure 1 It is a time-dependent diagram of the fluorescence spectrum during the synthesis of manganese-doped p...

Embodiment 2

[0028] Accelerated Preparation of Mn:CsPb(Br / Cl) 3 Quantum dots, comprising the steps of:

[0029] 1) Add 1 mmol PbBr 2 , 1 mmol Cs(AC) and 1 mmol MnCl 2 4H 2 Dissolve O in 1ml N, N-dimethylformamide (DMF) and ultrasonically dissolve it completely to make the required precursor solution;

[0030] 2) After mixing 6 ml of oleic acid, 0.8 ml of n-octylamine and 30 ml of n-hexane, add the PbBr obtained in step (1) dropwise in sequence 2 , Cs(AC) precursor solution, stirred for 8-10 minutes, the solution changed from clear to white emulsion, and CsPbBr was prepared 3 Quantum dot materials;

[0031] 3) The MnCl obtained in step 1) 2 Precursor solution was added dropwise to CsPbBr at a rate of 20-60 drops / min 3 Perovskite quantum dot solution, and quickly transfer the entire reaction to an ultrasonic instrument, only 15 to 20 minutes Mn:CsPb(Br / Cl) 3 The perovskite quantum dots can be prepared.

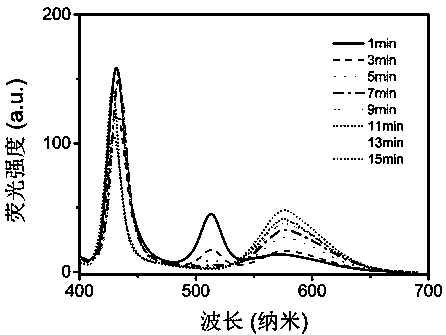

[0032] figure 2 In this embodiment, the fluorescence spectrum changes with ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com