A method of making a wall

A production method and wall technology, applied to walls, buildings, building components, etc., can solve problems such as inability to effectively meet market demand, lack of control of wall quality, and high labor intensity of workers, so as to improve production efficiency and increase total output , Avoid the effect of setting the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present application will be described in detail below. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

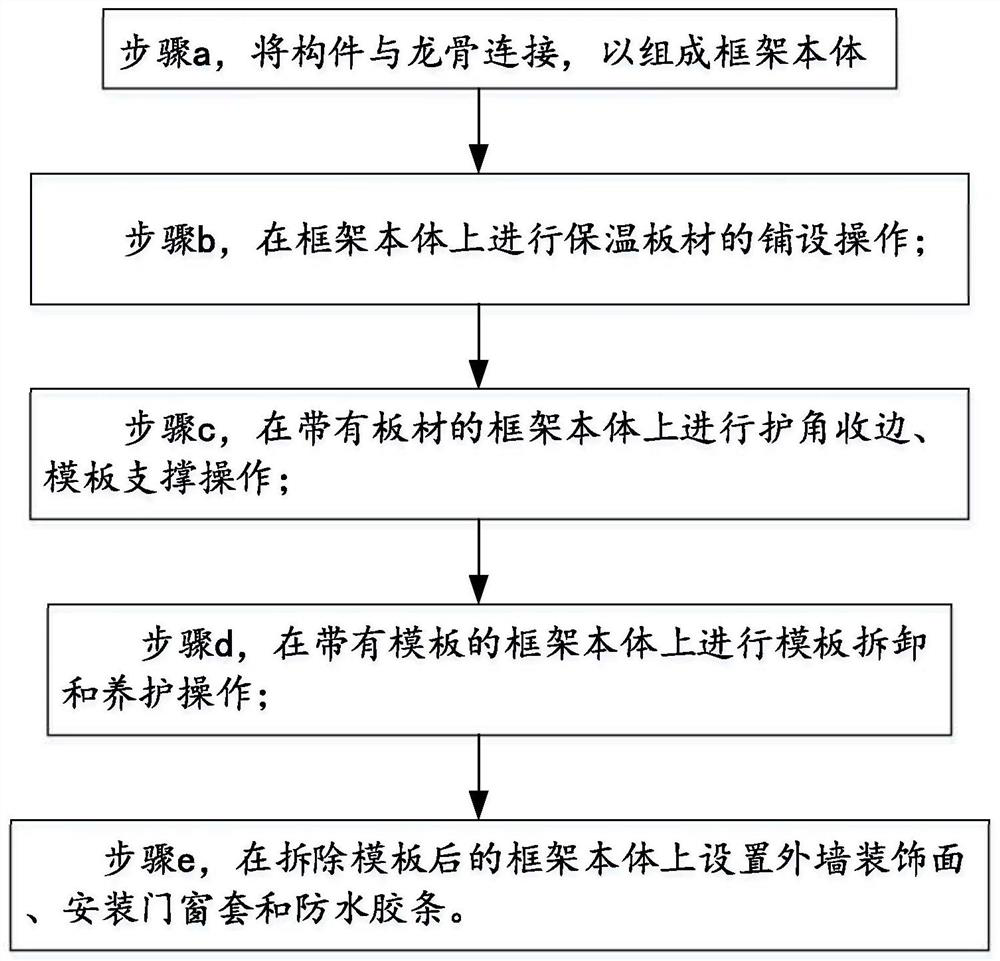

[0033] like figure 1 As shown, the embodiment of the present invention provides a method for making a wall, including the following steps:

[0034] Step a, connect the components with the keel to form the frame body; step b, lay the thermal insulation board on the frame body; step c, perform corner protection and formwork support operations on the frame body with the board; d. Carry out formwork removal and maintenance operations on the frame body with the formwork; step e, set the exterior wall decoration surface and install door and window covers and waterproof adhesive strips on the frame body after the formwork is removed.

[0035] In the specific operation, the present application can realize the convenient welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com