Drilling and installation integrated bolt construction equipment and using method thereof

A technology of bolt construction and drilling device, which is applied in drilling equipment and methods, installation of bolts, drilling equipment, etc. long, unable to use manual work and other problems, to achieve the effect of simple structure, reduce construction costs, and maintain cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

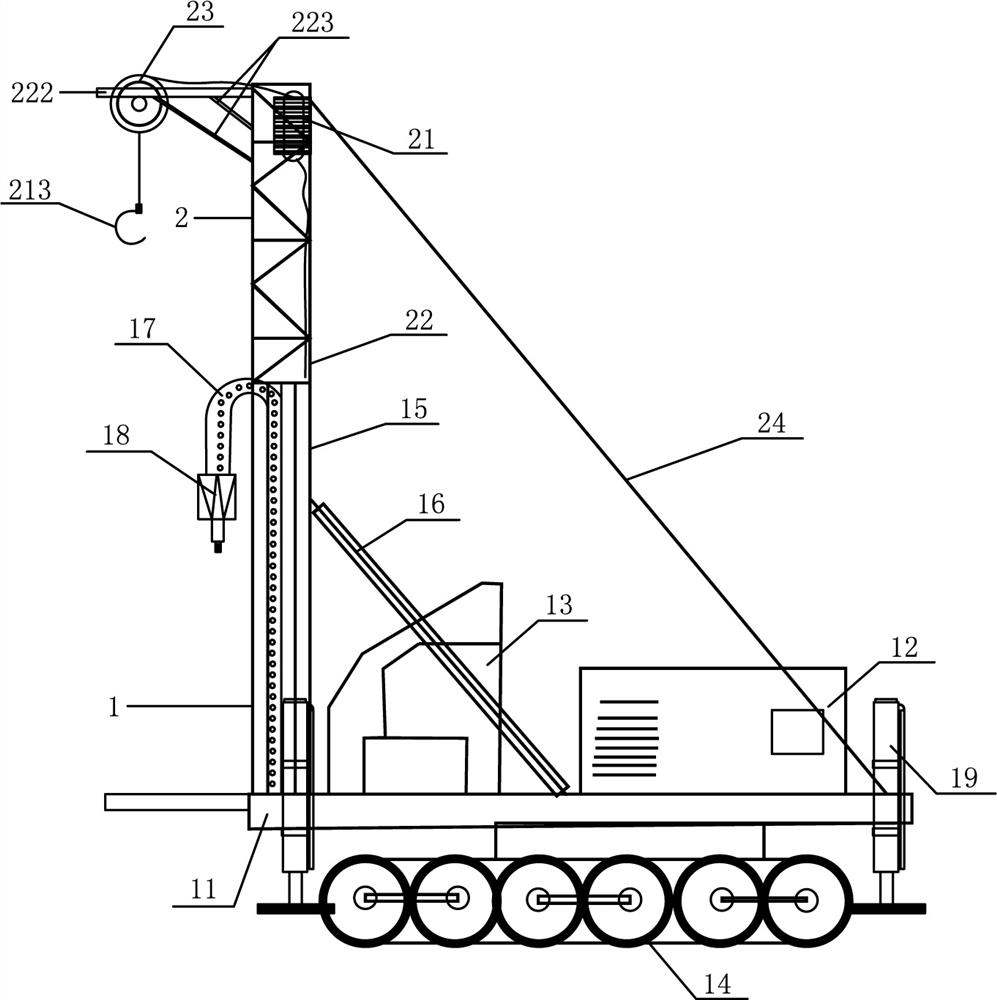

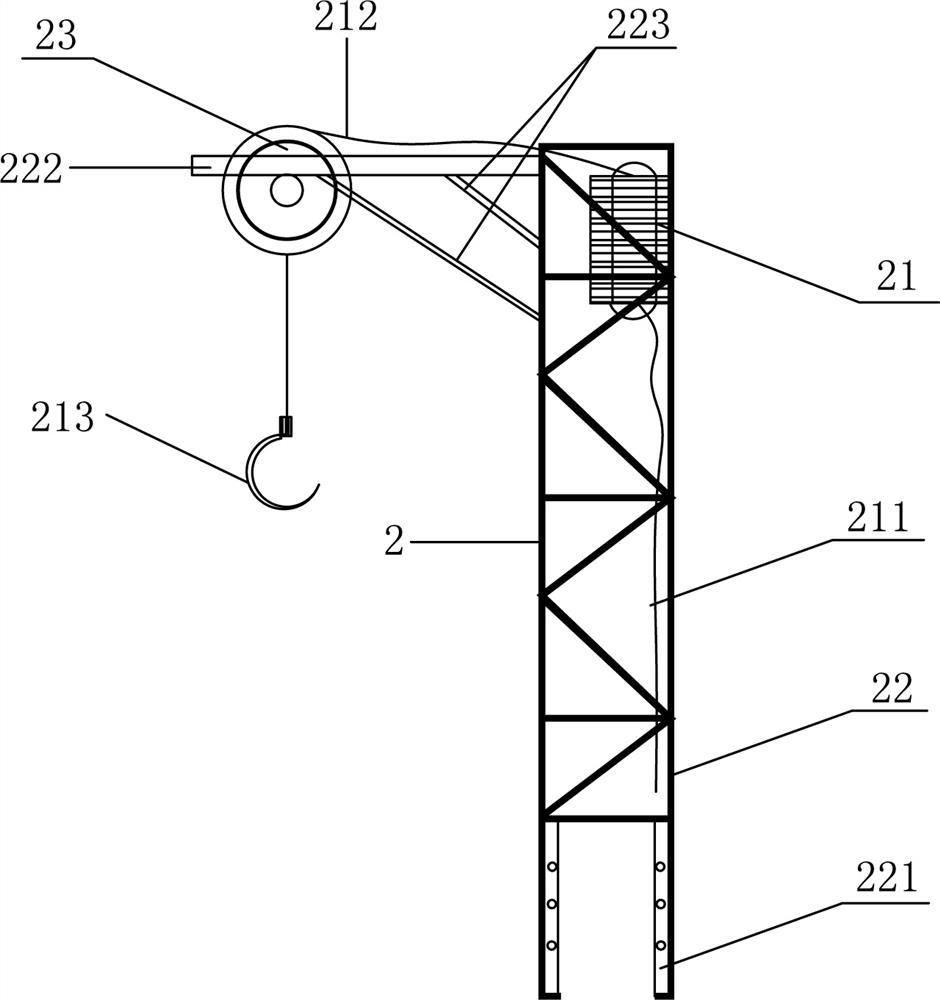

[0031] A kind of bolt construction equipment integrated with drilling and installation, including mobile drilling device 1 and hoisting device 2, such as figure 1 and figure 2 As shown, the specific structure is:

[0032] The mobile drilling device 1 includes a car body 11, an engine 12, a control room 13, wheels 14, a support 15, a hydraulic support rod 16, a drag chain 17, a drill bit 18 and a hydraulic jacking cylinder 19,

[0033] The car body 11 is provided with an engine 12 and a control room 13, and the lower part of the car body 11 is rotatably provided with wheels 14, and the engine 12 is connected to the wheels 14 through a transmission mechanism;

[0034] The front end of the car body 11 is vertically fixed to the support 15, supported by a hydraulic support rod 16 between the support 15 and the car body 11, the second half of the tow chain 17 is arranged in the support 15, and the front half of the tow chain 17 is arranged outside the support 15 , the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com