SOQ-based quartz vibration beam accelerometer chip with flexible amplifying mechanism

A technology of amplifying mechanism and accelerometer, which is applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, measuring device, etc. It can solve the problems affecting the accuracy of the sensor, the overall structure of the chip is large, and the amplification effect is discounted, so as to avoid cross-interference and avoid Stress difference, effect of avoiding assembly error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

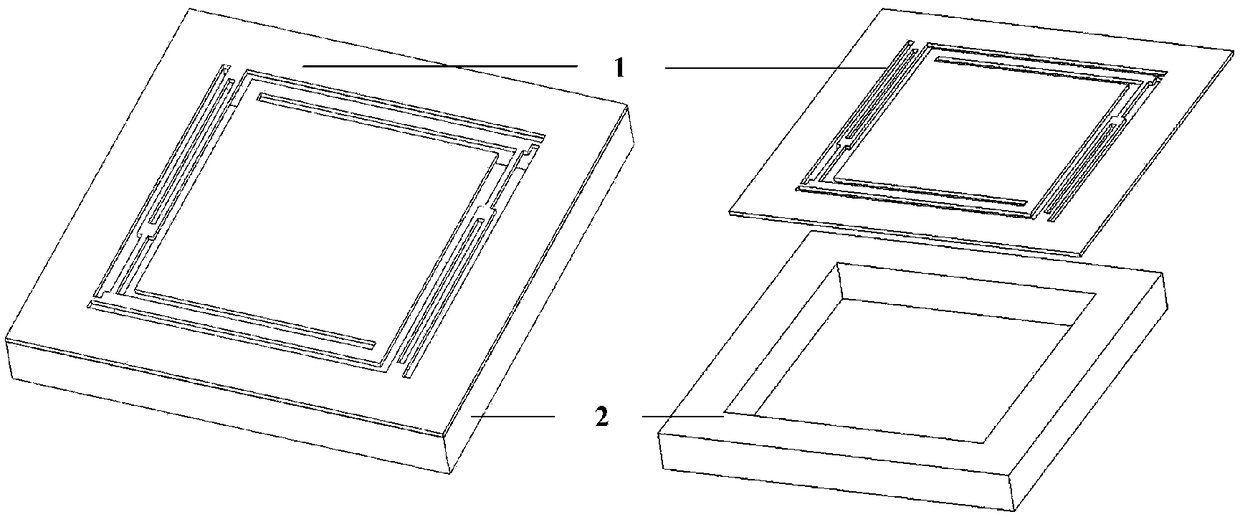

[0020] refer to figure 1 , a SOQ-based quartz beam accelerometer chip with a flexible amplification mechanism, including a bonded quartz structure 1 and a silicon structure 2.

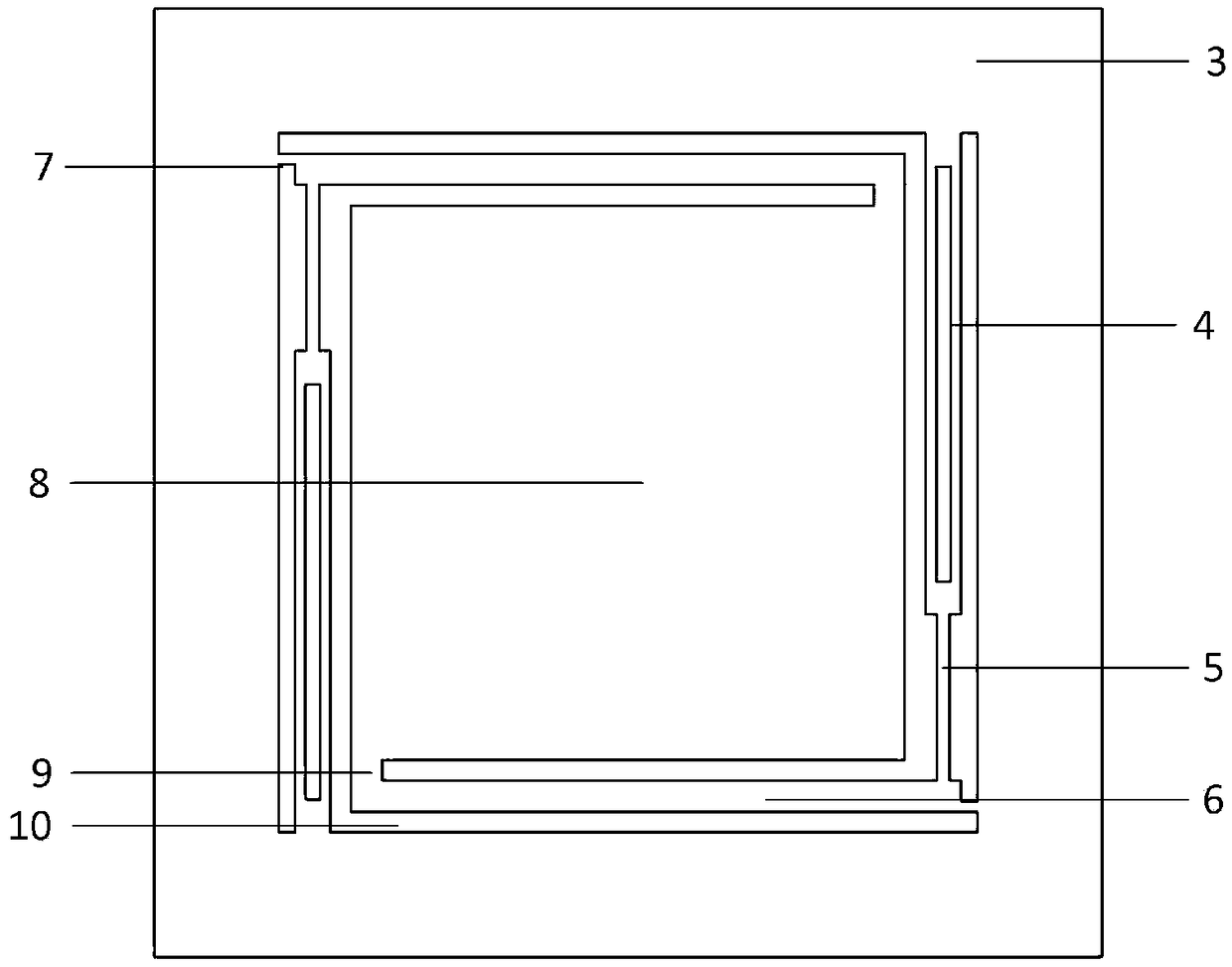

[0021] refer to figure 2 , the quartz structure 1 is an in-plane differential quartz beam chip structure composed of a quartz frame 3, a quartz tuning fork 4, a connecting rod 5, a lever 6, a hinge 7, a mass 8, an input end 9 and an etching gap 10 , wherein the quartz frame 3, as the supporting part of the overall structure and the bonding part with the silicon structure, is the fixed part of the quartz structure 1, and the rest are suspended movable structures; one end of the quartz tuning fork 4 is fixed on the quartz frame 3, and the other end is connected to the The rod 5 is connected, and is connected with the sensitive mass 8 through the lever 6 and the input end 9; 8 are connected;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com