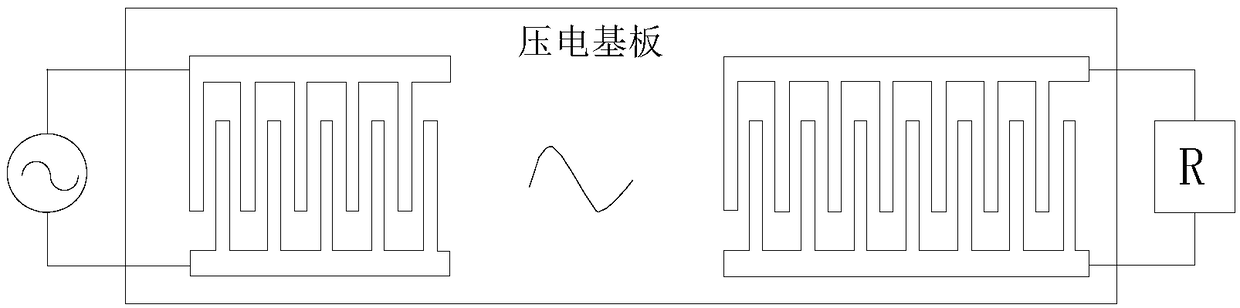

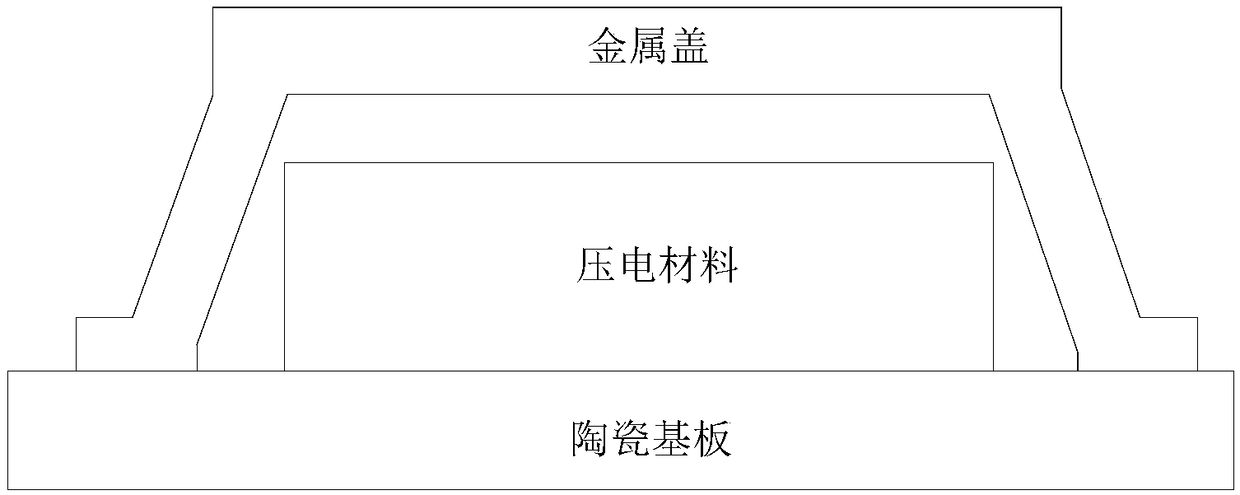

Quasi-air tightness surface acoustic wave component encapsulation structure and manufacturing method

A surface acoustic wave, packaging structure technology, applied in the manufacture/assembly of electrical components, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve cutting difficulties and differences in expansion coefficients Larger, lowering the hardness, brittleness and brittleness of massage materials, etc., to reduce material costs, improve production efficiency, and avoid waste gas residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

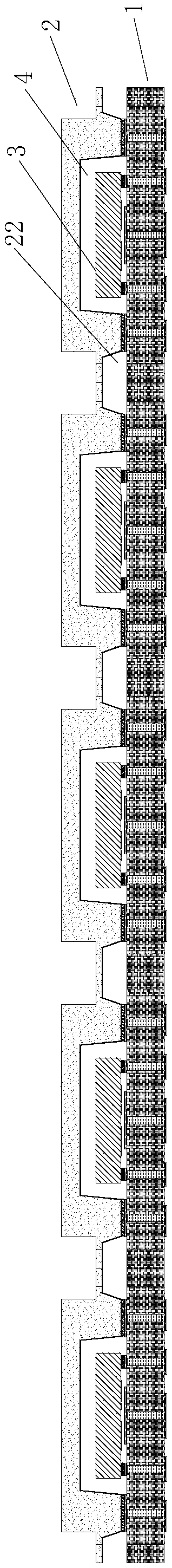

[0062] Such as Figure 3 ~ Figure 7 As shown, this embodiment provides a quasi-hermetic surface acoustic wave component packaging structure, which includes a substrate array 1 , a shielding cover array 2 and five surface acoustic wave chips 3 .

[0063] The substrate array 1 has five substrates 11, and each substrate 11 corresponds to a surface acoustic wave chip 3, which is made of resin-glass fiber composite material, which can reduce the cost, improve the dimensional accuracy and process adaptability of the substrate 11, including The upper and lower surface circuits and through-holes, the substrate 11 is made by a general-purpose high density interconnect (High Density Interconnector, HDI) process, and because the resin has a certain degree of water absorption, the packaging structure of this embodiment is quasi-airtight .

[0064] The five surface acoustic wave chips 3 are all surface acoustic wave wafers, and are mounted on the substrate array 1. Specifically, each surf...

Embodiment 2

[0077] Such as Figure 12 to Figure 16 As shown, this embodiment provides a quasi-hermetic surface acoustic wave component packaging structure, which includes a substrate array 1 , a shielding cover array 2 and four surface acoustic wave chips 3 .

[0078] The substrate array 1 has four substrates 11, and each substrate 11 corresponds to a surface acoustic wave chip 3, which is made of resin-glass fiber composite material, which can reduce the cost, improve the dimensional accuracy and process adaptability of the substrate 11, including The upper and lower surface circuits and through-holes, the substrate 11 is made by a general-purpose high density interconnect (High Density Interconnector, HDI) process, and because the resin has a certain degree of water absorption, the packaging structure of this embodiment is quasi-airtight .

[0079] The four surface acoustic wave chips 3 are all surface acoustic wave wafers, and are mounted on the substrate array 1. Specifically, each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com