Novel hydraulic driving vertical spiral deep ploughing machine

A vertical spiral and deep tiller technology, applied in the direction of tillage machines, agricultural machinery and tools, applications, etc., can solve problems such as increased maintenance costs, increased farming time, and other personnel injuries, to achieve enhanced fertility and soil water storage and drought resistance, Improves the degree of crushing and prolongs the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

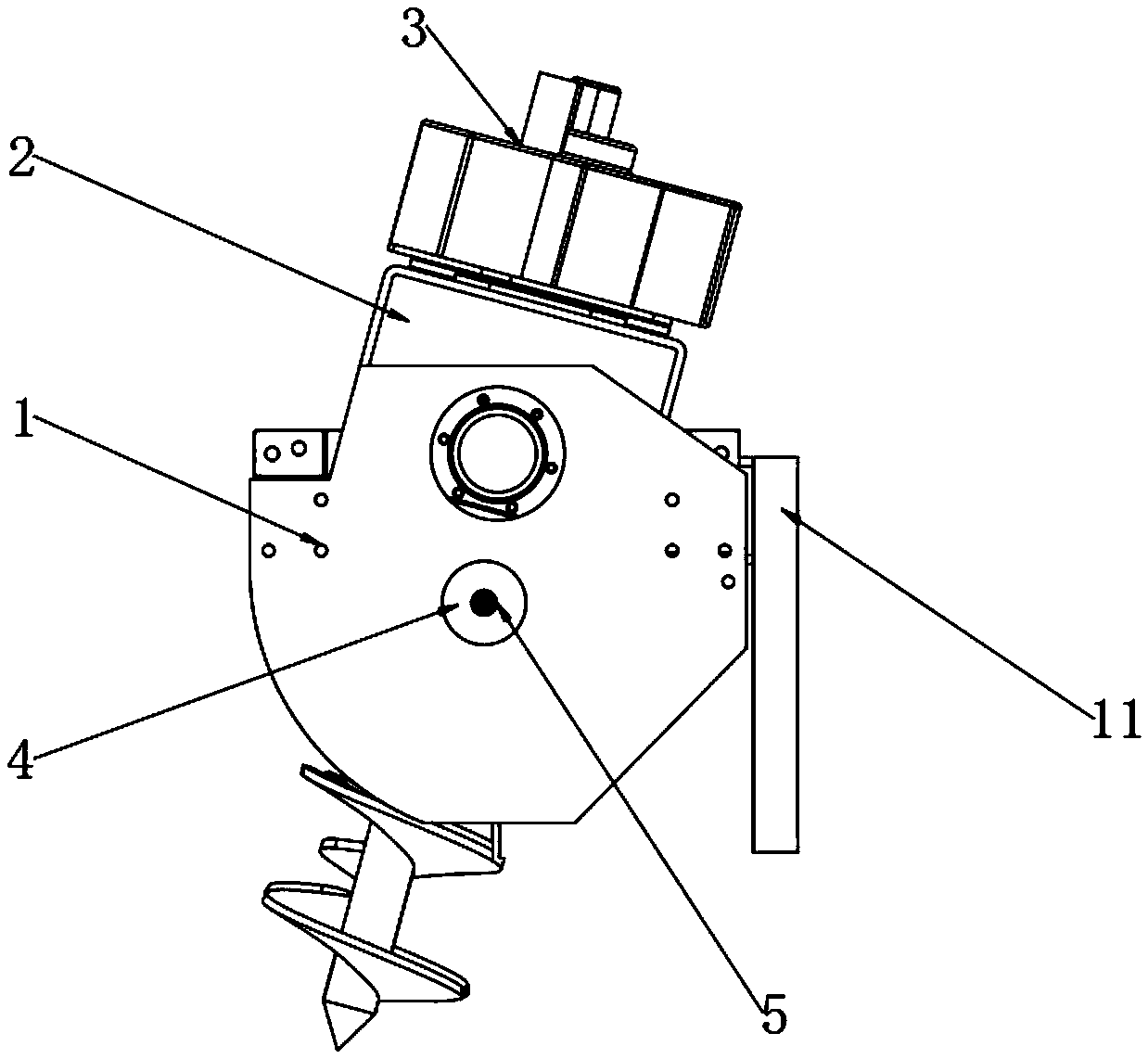

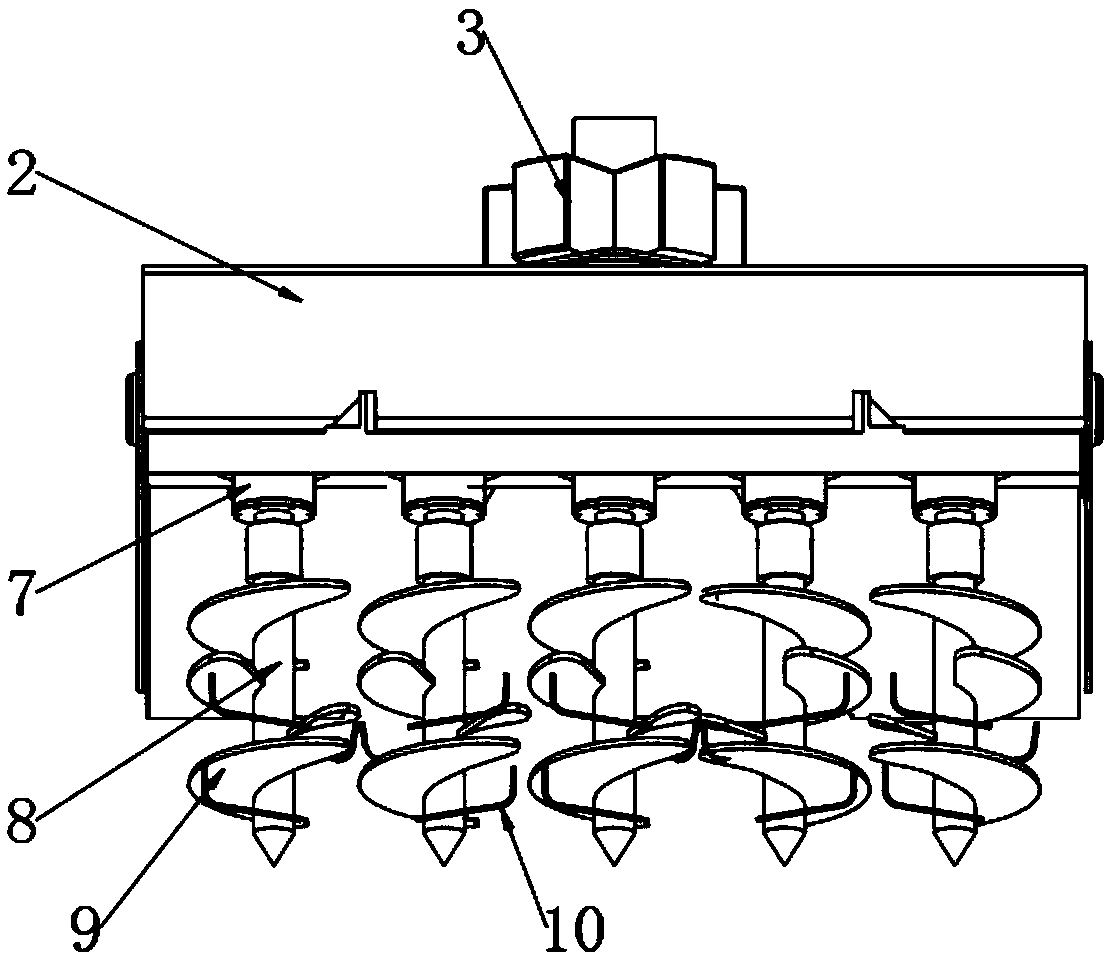

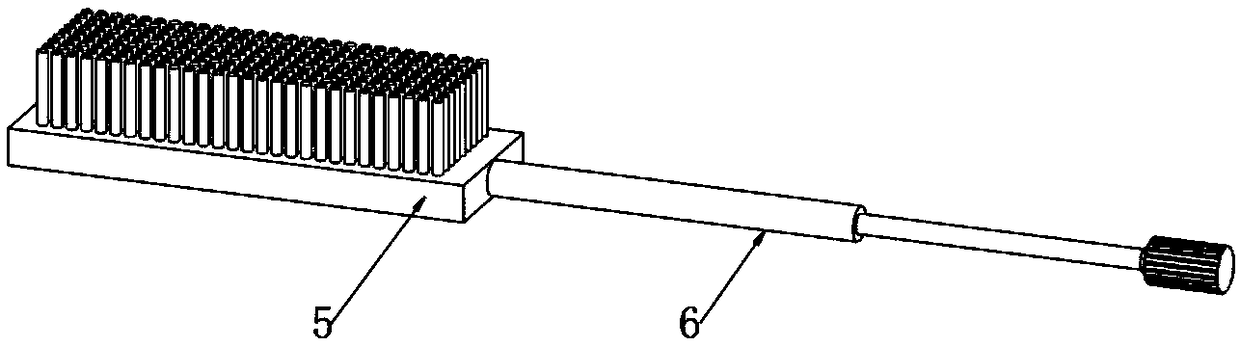

[0032] Example: such as Figure 1-8As shown, the present invention provides a technical solution, a new type of hydraulically driven vertical screw deep tiller, including a casing 1, in order to facilitate the desilting of the device, a storage groove 4 is provided on one side of the casing 1, in order to avoid steel The brush 5 slides out, a shielding cover is installed on the outside of the storage tank 4, and a steel brush 5 is stored inside the storage tank 4, and a telescopic rod 6 is installed on one side of the steel brush 5. One end of the rod 6 is equipped with a handle, and the outer side of the handle is provided with anti-slip lines. The upper end of the casing 1 is installed with a reduction box 2, and the upper end of the reduction box 2 is installed with a hydraulic drive motor 3. Including fixing column 701, shock absorbing assembly 702, fixing nut 703, fixing plate 704, sealing groove 705, connecting hole 706, power shaft 707, mounting plate 708, fixing screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com