Active heat storing and heat supplying system of green house

A greenhouse and heating system technology, applied in heat recovery systems, greenhouse cultivation, heat pumps, etc., can solve problems such as limited heat storage capacity, high operating costs, and conventional energy consumption, so as to improve regulation and control capabilities and enhance heat storage and heat preservation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

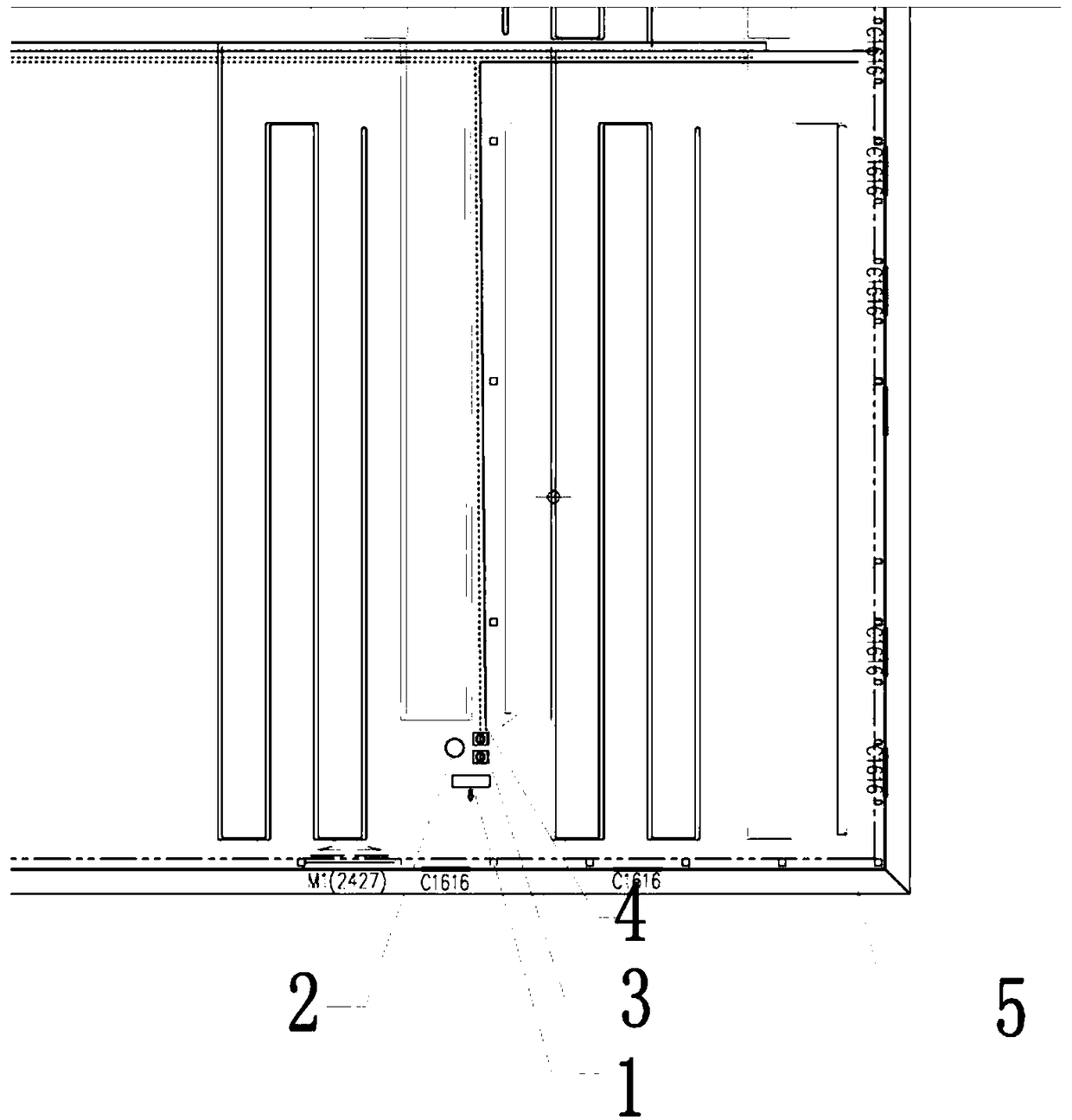

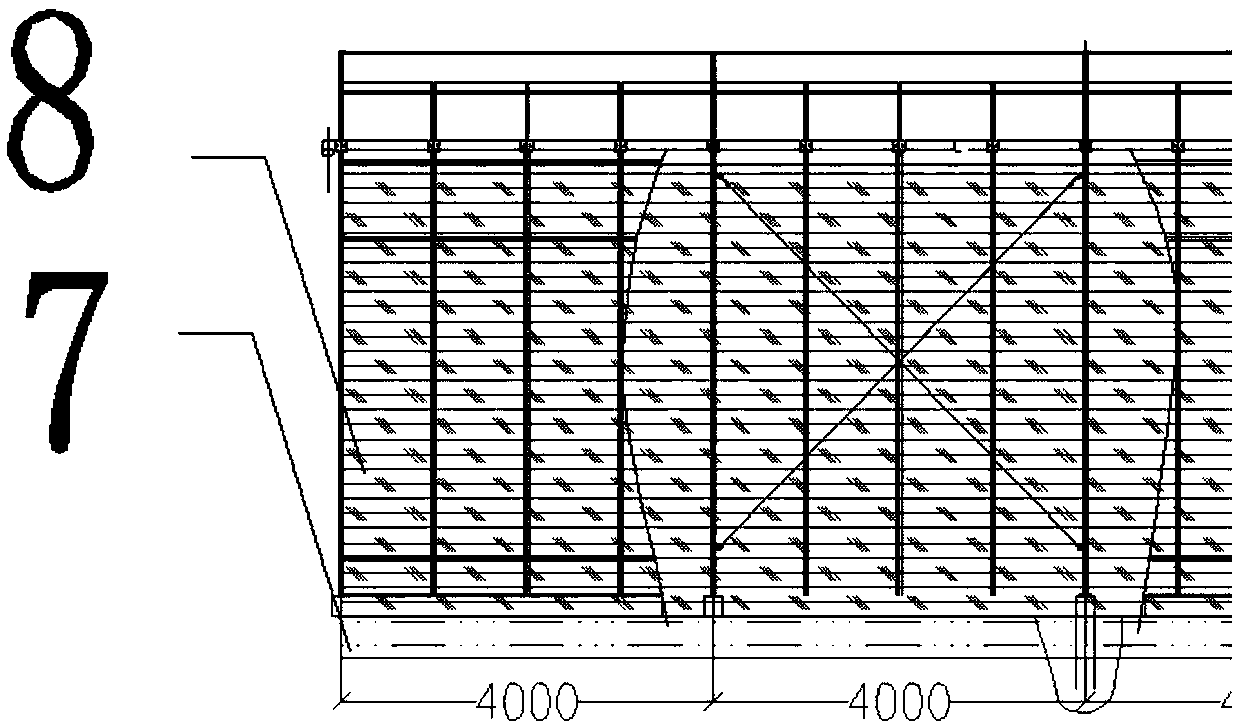

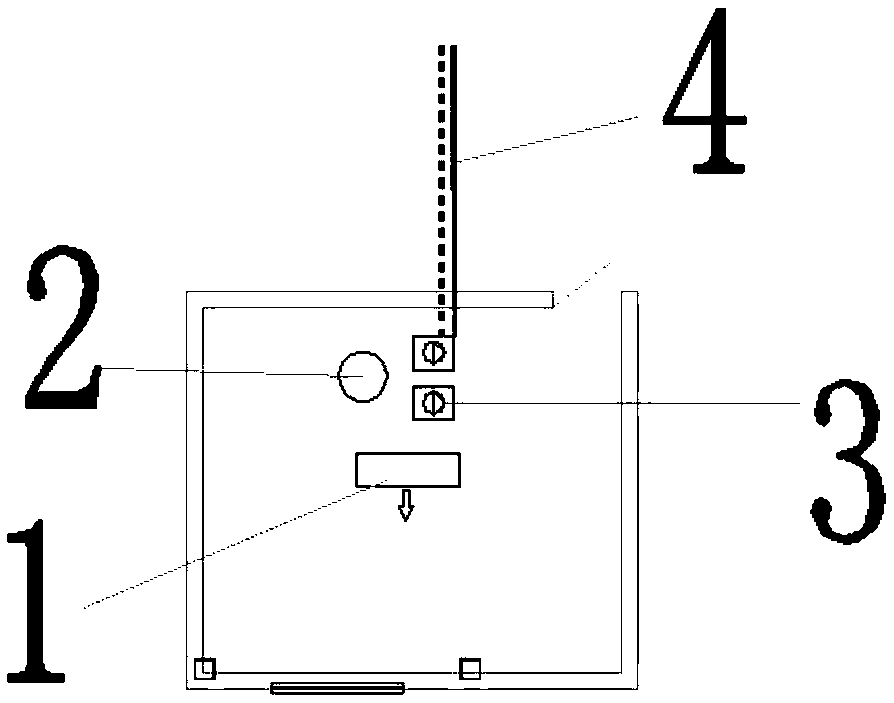

[0048] Such as Figure 1-4As shown, the greenhouse active heat storage and heating system provided in this embodiment includes an integral air source heat pump host 1, a heat storage buffer water tank 2, a heating circulation pump 3, an insulation pipe 4, a heat storage and heat supply coil 5, and an electric adjustment Valve 6, heat conduction insulation layer 7, insulation layer around the greenhouse 8, indoor insulation layer 12 of the greenhouse, controller 9, temperature sensor 10 and electric heating control valve 11; an air source heat pump host 1 is installed in the greenhouse, and The heat storage buffer water tank 2 is connected through pipelines, and the integral air source heat pump host 1 heats or raises the water temperature of the heat storage buffer water tank 2 through a heat exchanger. The heat storage and heating coil 5 is buried in the greenhouse, and the heat storage buffer water tank 2 and The heat storage heating coil 5 is connected to the heating circul...

Embodiment 2

[0055] This embodiment has basically the same technical features as Embodiment 1, which will not be repeated here. The difference is that in this embodiment, a greenhouse indoor insulation layer 12 is also provided in the greenhouse, as shown in the attached Figure 5 shown. On the one hand, the indoor insulation layer of the greenhouse can reduce the loss of heat in the greenhouse, so as to achieve the effect of heat preservation; on the other hand, the indoor insulation layer of the greenhouse can also be unfolded, which can isolate the moisture in the greenhouse and reduce the condensed water on the roof. It is more conducive to the growth of crops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com