Processing method of corn oil capable of reducing blood lipid

A processing method and corn oil technology, applied in the directions of edible oil/fat, food science, application, etc., can solve problems such as prohibitiveness, and achieve the effect of good blood lipid lowering, improving blood lipid lowering effect, and improving oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

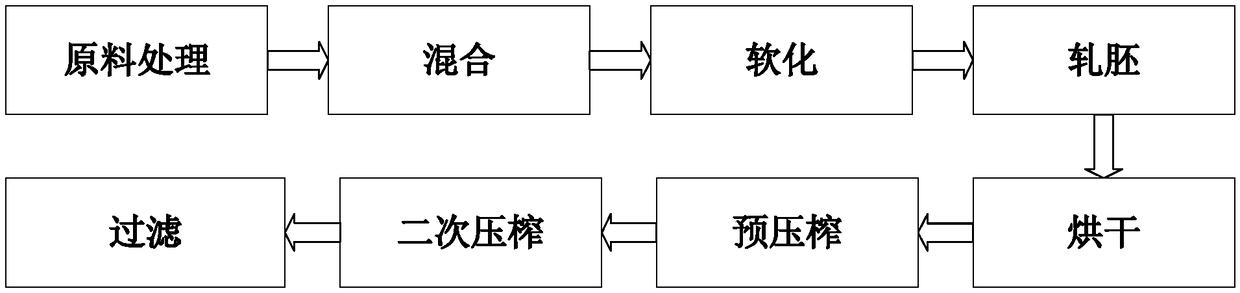

[0025] The processing method of a kind of hypolipidemic corn oil provided by the present invention comprises the following steps, see attached figure 1 :

[0026] (1) Raw material processing: select corn germ for cleaning, drying, cooling, and peeling; separate endosperm and skin to obtain corn germ with a skin content of 1%; wash rhubarb and Bupleurum radix, and cut into 1.5mm pellets;

[0027] (2) Mixing: in step (1), corn germ, rhubarb and Bupleurum are mixed according to a weight ratio of 100:3:1.5;

[0028] (3) Softening: use steam to steam the mixture in step (2); the temperature of the steam is 75° C., and the steaming time is 20 minutes.

[0029] (4) flaking: the softened mixture in step (3) is flaked, and the thickness of the flaked flakes is 0.3mm;

[0030] (5) Drying: drying the mixture after flaking in step (4), at a drying temperature of 30° C., to obtain corn germ with moisture reduced to 7%;

[0031] (6) Pre-pressing: the mixture in step (5) is pre-pressed by...

Embodiment 2

[0035] The processing method of a kind of hypolipidemic corn oil provided by the present invention comprises the following steps, see attached figure 1 :

[0036] (1) Raw material processing: select corn germ for cleaning, drying, cooling, and peeling; separate endosperm and skin to obtain corn germ with a skin content of 0.8%; wash rhubarb and Bupleuri, and cut into 1mm;

[0037] (2) Mixing: in step (1), corn germ, rhubarb and Bupleurum are mixed according to a weight ratio of 110:4:2;

[0038] (3) Softening: use steam to steam the mixture in step (2); the temperature of the steam is 70° C., and the steaming time is 25 minutes.

[0039] (4) flaking: the softened mixture in step (3) is flaked, and the thickness of the flaked flakes is 0.25mm;

[0040] (5) Drying: drying the mixture after flaking in step (4), at a drying temperature of 40° C., to obtain corn germ with moisture reduced to 5%;

[0041] (6) Pre-pressing: the mixture in step (5) is pre-pressed by a press to obta...

Embodiment 3

[0045] The processing method of a kind of hypolipidemic corn oil provided by the present invention comprises the following steps, see attached figure 1 :

[0046] (1) Raw material processing: select corn germ for cleaning, drying, cooling, and peeling; separate endosperm and skin to obtain corn germ with a skin content of 0.5%; wash rhubarb and Bupleuri, and cut into 2 mm;

[0047] (2) Mixing: in step (1), corn germ, rhubarb and Bupleurum are mixed according to a weight ratio of 120:5:3;

[0048] (3) Softening: use steam to steam the mixture in step (2); the temperature of the steam is 80° C., and the steaming time is 20 minutes.

[0049] (4) flaking: the softened mixture in step (3) is flaked, and the thickness of the flaked flakes is 0.3mm;

[0050] (5) Drying: drying the mixture after flaking in step (4), at a drying temperature of 40° C., to obtain corn germ with moisture reduced to 5%;

[0051] (6) Pre-pressing: the mixture in step (5) is pre-pressed by a press to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com