Fermented feed produced by microbial treatment and explosion of crop straw and production method and applications of feed

A technology for crop straw and microbial treatment, applied in animal feed, animal feed, application, etc., can solve the problems of feed waste, high fiber content, and inability of animals to completely digest and absorb nutrients, so as to reduce pollution, increase treatment channels, and benefit The effect of nitrogen balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

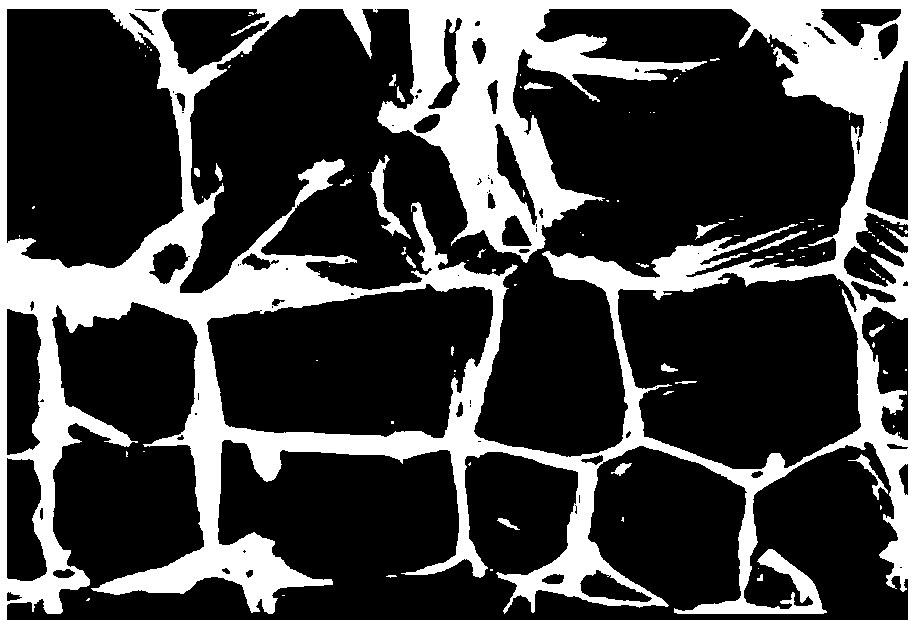

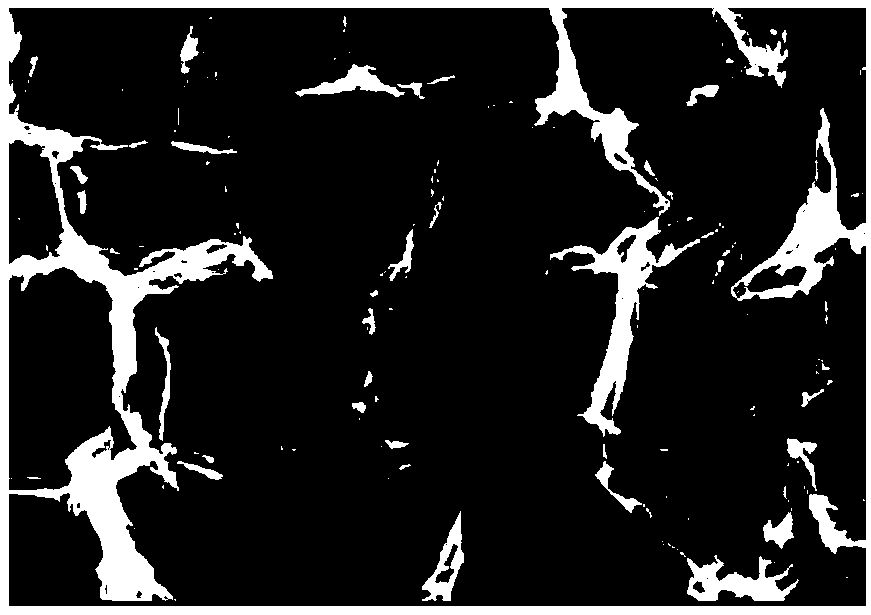

Image

Examples

Embodiment 1

[0044] A method for microbial treatment of blasted corn stalks to produce fermented feed, comprising the following steps:

[0045] 1) Soak the air-dried corn stalks in 3 times the weight of water, and steam blast 150 g of wet corn stalks under a pressure of 1.0 MPa for 45 seconds to obtain blasting stalks;

[0046] Determination of xylose content in the blasted straw, the specific method is as follows:

[0047] (1) Drawing of xylose standard curve

[0048] Take 7 test tubes and prepare xylose standard solutions with different concentrations according to the data in the table below. Place in a boiling water bath for 10 minutes, then rapidly cool to room temperature, dilute to 25mL, and shake well. Use a 10mm colorimetric tube, preheat it in a water bath at 60°C for 5 minutes, add DNS reagent, and measure the absorbance at a wavelength of 540nm with a spectrophotometer. With the amount of glucose as the abscissa and the absorbance as the ordinate, a standard curve will be dra...

Embodiment 2

[0071] A method for microbial treatment of blasted corn stalks to produce fermented feed, comprising the following steps:

[0072] 1) Soak the air-dried corn stalks in water for 24 hours, and steam-explode 150 g of wet crop stalks for 30 s under a pressure of 0.8 MPa to obtain the blasted straws; measure the xylose content of the blasted straws according to the method of Example 1, and the result is 1.1213 ( U / mL).

[0073] Dry the obtained blasting stalks at 60° C., crush them to obtain corn stalks for fermentation, and set 3 parallels for each fermentation group.

[0074] 2) Mix the above-mentioned corn stalks for fermentation with water at a mass ratio of 1:2, then add corn steep liquor to the obtained material, the amount of corn steep liquor added is 7% of the mass of corn stalks for fermentation, and add to the obtained mixed material According to the inoculum amount of 3%, the fermented bacterial liquid was inserted, and fermented at 30° C. for 5 days to obtain ferment...

Embodiment 3

[0079] A method for microbial treatment of blasted corn stalks to produce fermented feed, comprising the following steps:

[0080] 1) The air-dried corn stalks were soaked in water for 24 hours, and 150 g of wet corn stalks were steam-exploded for 45 seconds under a pressure of 0.8 MPa to obtain the blasted straws; the xylose content of the blasted straws was measured according to the method of Example 1, and the result was 1.2148 ( U / mL).

[0081] Dry the obtained blasting stalks at 60° C., crush them to obtain corn stalks for fermentation, and set 3 parallels for each fermentation group.

[0082] 2) Mix the above-mentioned corn stalks for fermentation with water at a mass ratio of 1.5:1, then add corn steep liquor to the obtained material, the amount of corn steep liquor added is 9% of the mass of corn stalks for fermentation, and add to the obtained mixed material According to the inoculum amount of 11%, the fermented bacterial liquid was inserted, and fermented at 35° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com