Novel two-dimensional black phosphorus nanosheet-MoS2 composite solar hydrogen production material as well as preparation method and application thereof

A nanosheet and solar energy technology, which is applied in the field of new two-dimensional black phosphorus nanosheet-MoS2 composite solar hydrogen production materials, can solve the problems of weak absorption of visible light and near-infrared light, containing precious metals, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

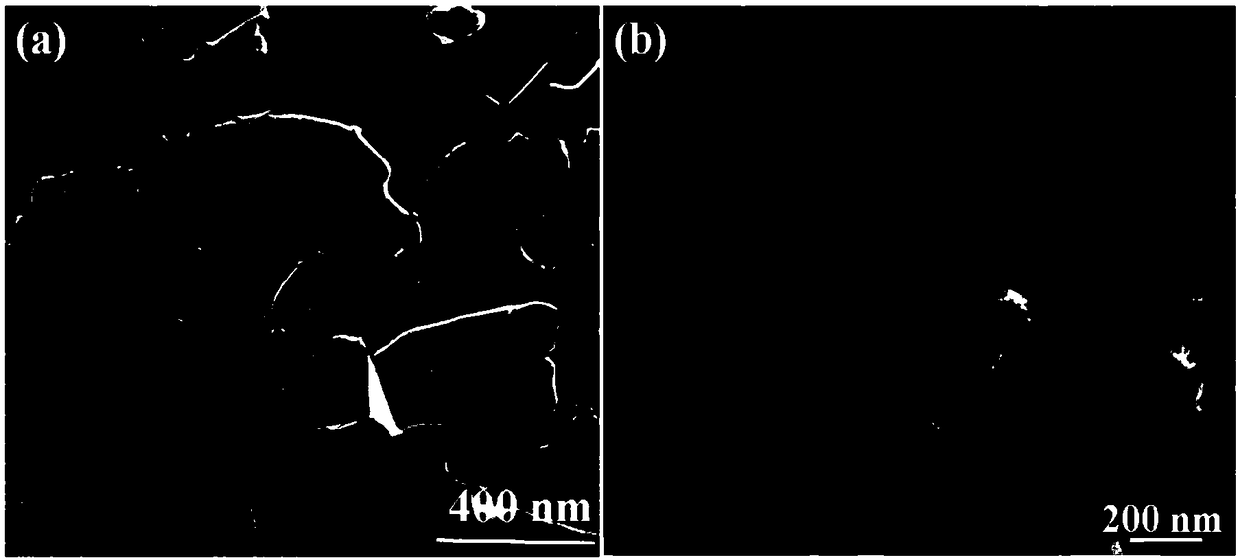

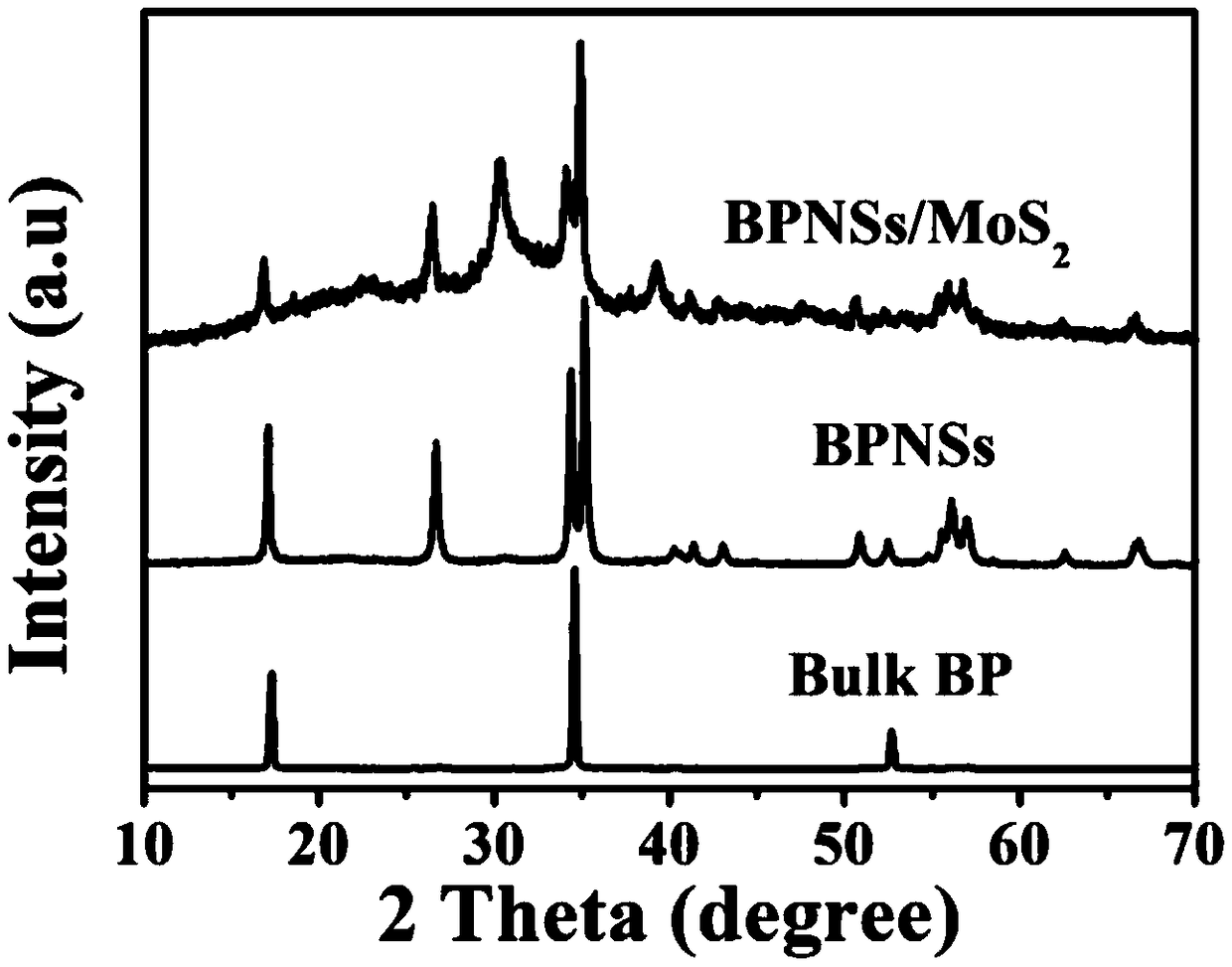

[0023] Add 20 mg of black phosphorus crystal powder and 20 mg of NaOH to 50 ml of N-methylpyrrolidone solution, sonicate for 24 hours in a cell disruption ultrasonicator, and then centrifuge at 2500 rpm / min for 10 minutes to remove large black phosphorus particles, and collect the upper suspension. The suspension was centrifuged at 10,000 rpm / min for 10 minutes, and the resulting fine black phosphorus nanosheet solids were collected. Such as figure 1 As shown in (a), the size of black phosphorus nanosheets is in the range of 100-500nm. image 3 The XRD plot of black phosphorus nanosheets is given, which proves the generation of black phosphorus nanosheets.

Embodiment 2-1

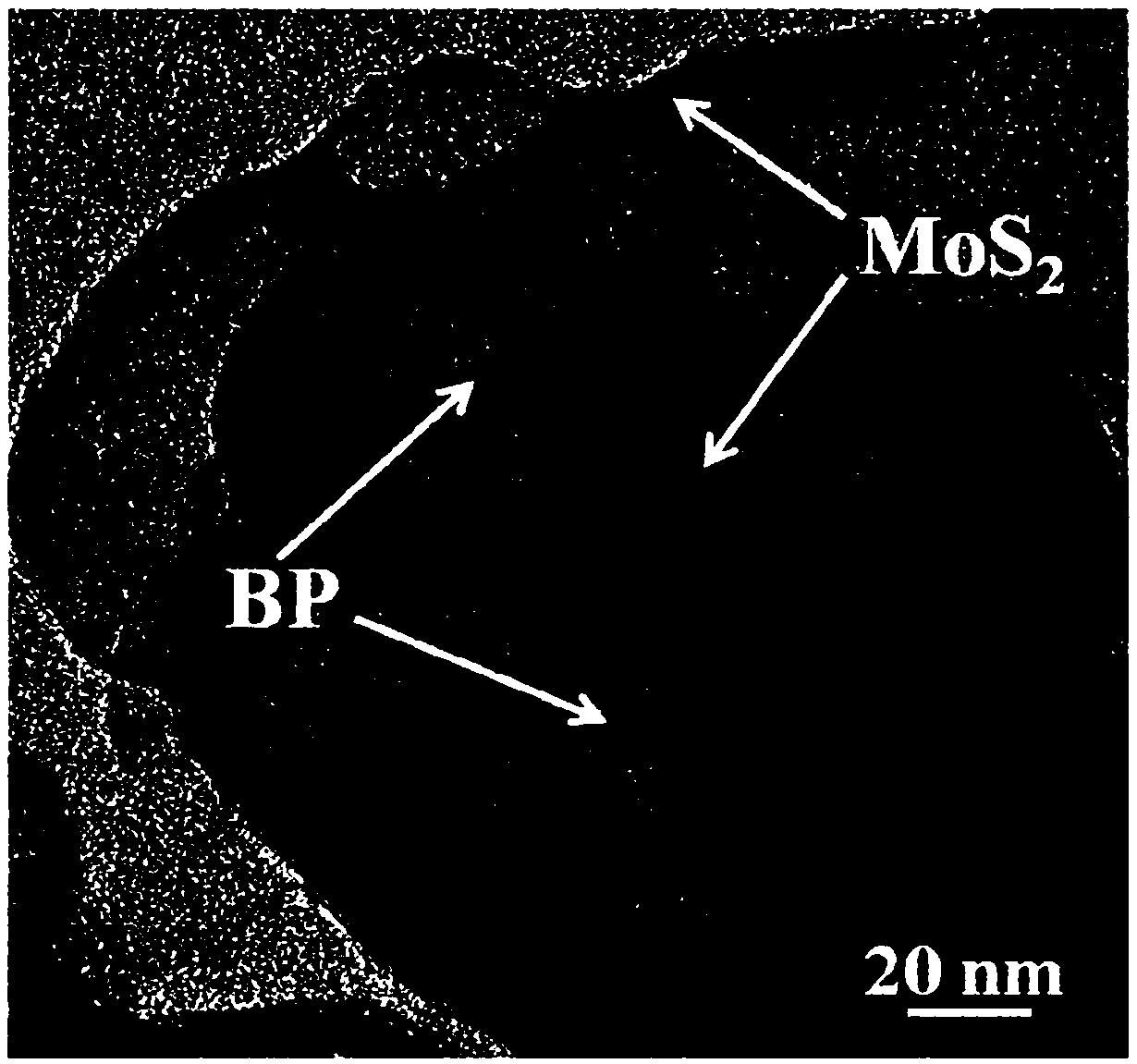

[0025] 40ml of N,N-dimethylformamide (DMF) solution containing 10mg of black phosphorus nanosheets and 16mg of ammonium tetrathiomolybdate was added to a reactor with a capacity of 50ml, and the reactor was reacted at 200°C for 24h. After cooling to room temperature after the reaction, centrifuge at 4000rpm / min to obtain black phosphorus nanosheets / MoS 2 (1:1) Composite solar hydrogen production materials. Such as figure 1 As shown in (b), the size of black phosphorus nanosheets is in the range of 100-500nm, with a typical two-dimensional structure. Such as figure 2 As shown in the TEM image, black phosphorus nanosheets successfully grew MoS 2 Nanosheets have a typical two-dimensional structure. image 3 Black phosphorus nanosheets / MoS 2 (1:1) XRD map, which proves that black phosphorus nanosheets / MoS 2 (1:1) generation.

Embodiment 2-2

[0027] 40ml of N,N-dimethylformamide (DMF) solution containing 50mg of black phosphorus nanosheets and 16mg of ammonium tetrathiomolybdate was added to a reactor with a capacity of 50ml, and the reactor was reacted at 180°C for 25h. After cooling to room temperature after the reaction, centrifuge at 4000rpm / min to obtain black phosphorus nanosheets / MoS 2 (5:1) Composite solar hydrogen production materials. Such as figure 1 As shown in (b), the size of black phosphorus nanosheets is in the range of 100-500nm, with a typical two-dimensional structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com