Rhodium-doped strontium titanate inverse opal material, production method of rhodium-doped strontium titanate inverse opal material and application of rhodium-doped strontium titanate inverse opal material in piezoelectric synergistic photocatalytic removal of organic pollutants

An inverse opal, strontium titanate technology, applied in water pollutants, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limiting practical applications, and achieve improved light energy conversion efficiency, good thermal stability, and improved The effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of strontium titanate inverse opal material of the present invention is as follows:

[0032] (1) Self-assemble monodisperse polystyrene microspheres on the conductive side of FTO glass by vertical deposition method to prepare three-dimensional ordered photonic crystal opal templates;

[0033] (2) Dip the three-dimensional ordered photonic crystal opal template into a solution containing titanium source and strontium source, and then prepare strontium titanate inverse opal material by calcination.

[0034] The preparation method of rhodium-doped strontium titanate inverse opal material is as follows:

[0035] (1) Self-assemble monodisperse polystyrene microspheres on the conductive side of FTO glass by vertical deposition method to prepare three-dimensional ordered photonic crystal opal templates;

[0036] (2) The three-dimensional ordered photonic crystal opal template is immersed in a solution containing rhodium source, titanium source, and stro...

Embodiment 1

[0040] Preparation of photonic crystal opal template: prepared by vertical deposition method, firstly ultrasonicated FTO glass with acetone, ethanol and deionized water for 20 min; then dispersed the freeze-dried 280 nm polystyrene microsphere powder into deionized water to obtain 0.125 wt% monodisperse polystyrene microsphere emulsion. Then measure the monodisperse polystyrene microsphere emulsion that the concentration of 1 ml is 0.125 wt% in a weighing bottle, put the FTO glass that is ultrasonically clean with the conductive side up into the weighing bottle vertically, place The weighing bottle is properly tilted so that the liquid level just touches the edge of the FTO glass substrate (that is, the monodisperse polystyrene microsphere emulsion is spread on the conductive side of the FTO glass), and then placed in an electric heating constant temperature incubator at 45°C , keeping for two days (48 hours), a three-dimensional ordered photonic crystal template can be prepar...

Embodiment 2

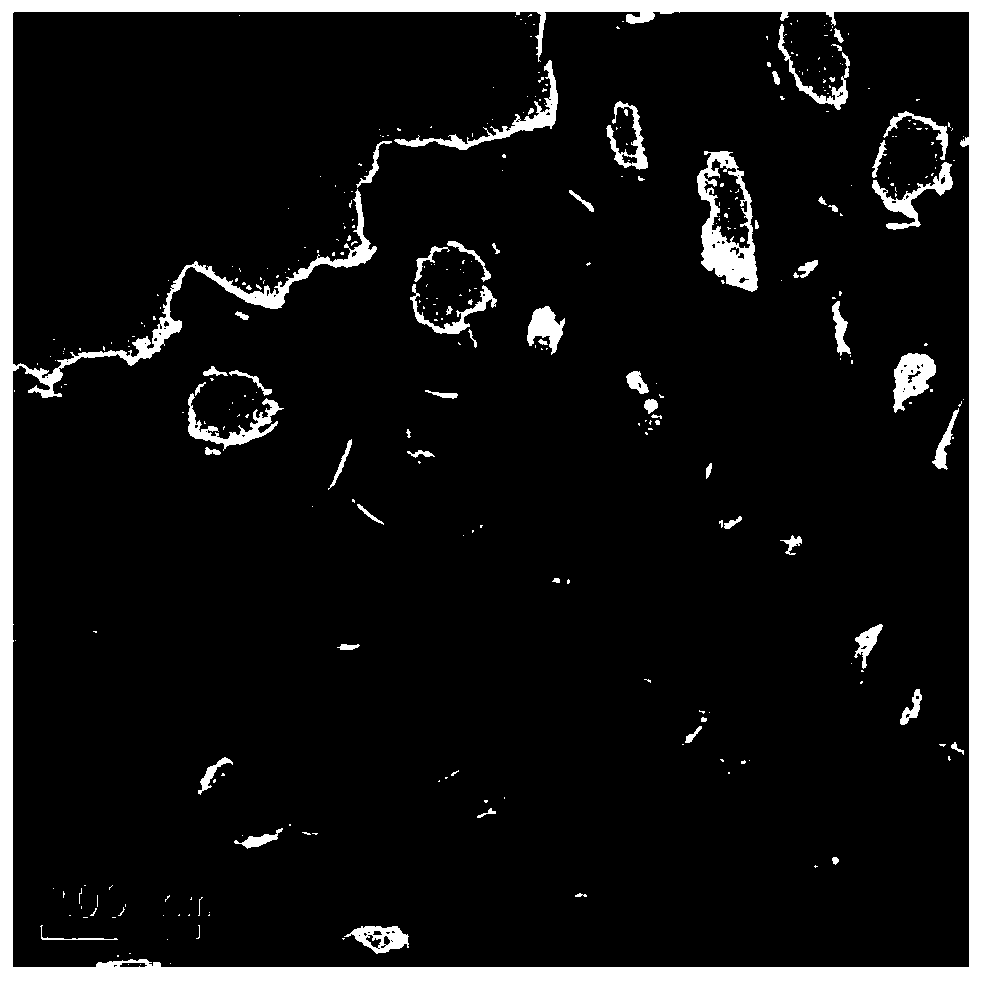

[0042] Preparation of strontium titanate inverse opal: First, 0.01 mol of tetrabutyl titanate was mixed with 10 mL of acetic acid, and then 10 mL of deionized water was added dropwise to the solution under continuous stirring. After that, 10 mL of 1M Sr(NO 3 ) 2 . Finally, add another 10 mL of 2M citric acid solution. The resulting solution was stirred at room temperature for an additional 30 minutes to obtain a clear solution, designated as solution A. The prepared polystyrene opal template was soaked in solution A, and then dried in an oven at 60 °C, and then the dried precursor template was calcined in air for 2 h in a tube furnace at a calcination temperature of 650 °C. The heating rate was 2 ℃ / min (from room temperature to 650 ℃), and natural cooling was used to obtain strontium titanate inverse opal thin film photocatalyst (SrTiO 3 IO). From attached figure 1 It can be seen that the strontium titanate inverse opal has a three-dimensional ordered macroporous structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com