Casting mould for car chassis shell

A technology for casting molds and automobile chassis, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., and can solve the problems of low production efficiency and low yield of shell casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

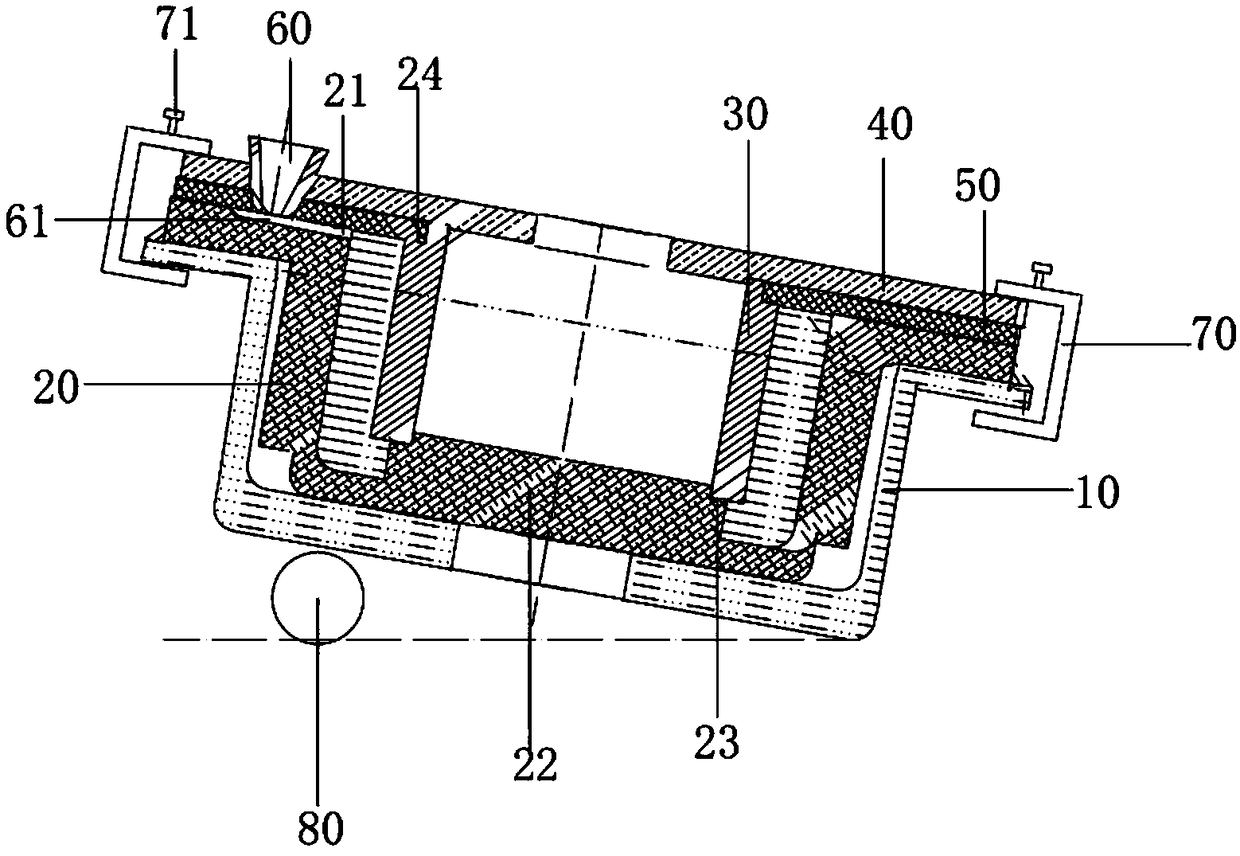

[0021] read on figure 1 As shown, a casting mold for an automobile chassis shell of the present invention includes a lower box 10 , an upper box 40 , a box cover 50 and a slope adjustment body 80 .

[0022] Wherein, the slope adjusting body 80 is used to adjust the inclination angle of the lower box 10, and the lower box 10, the upper box 40 and the box cover 50 form a whole.

[0023] read on figure 1 As shown, the slope adjustment body 80 of the present invention is wedge-shaped and installed on the bottom of the lower case 10, the lower case 10 is provided with an accommodating cavity, the upper case 40 is covered on the top of the lower case 10, and the upper case 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com