Refractory lining and nozzle thermal-shock-resisting protection layer of rotary kiln

A technology of refractory lining and rotary kiln, which is applied in the direction of coating, layered products, integral lining, etc., can solve the problems of insufficient thermal shock resistance, achieve energy saving and consumption reduction, increase production, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

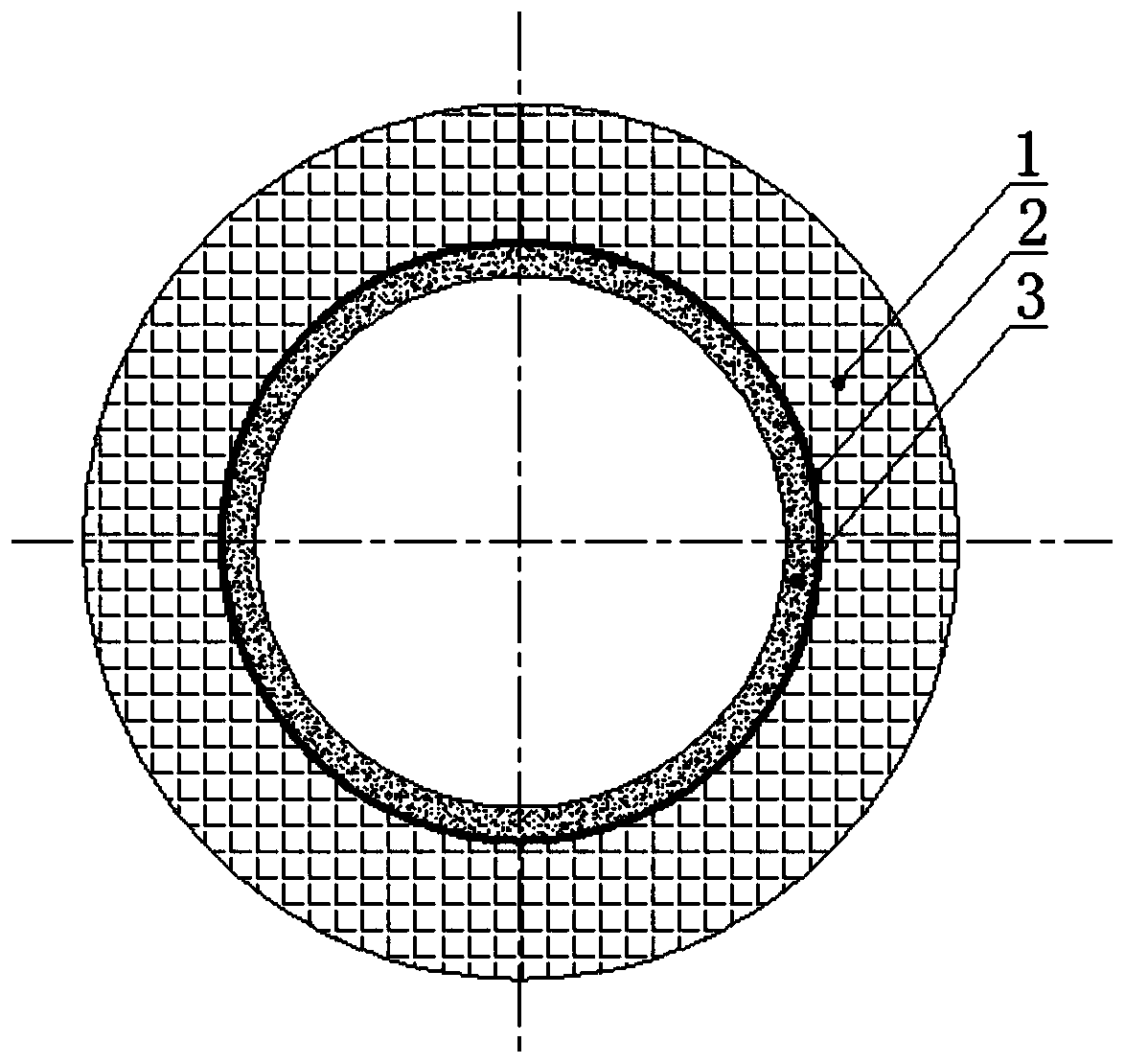

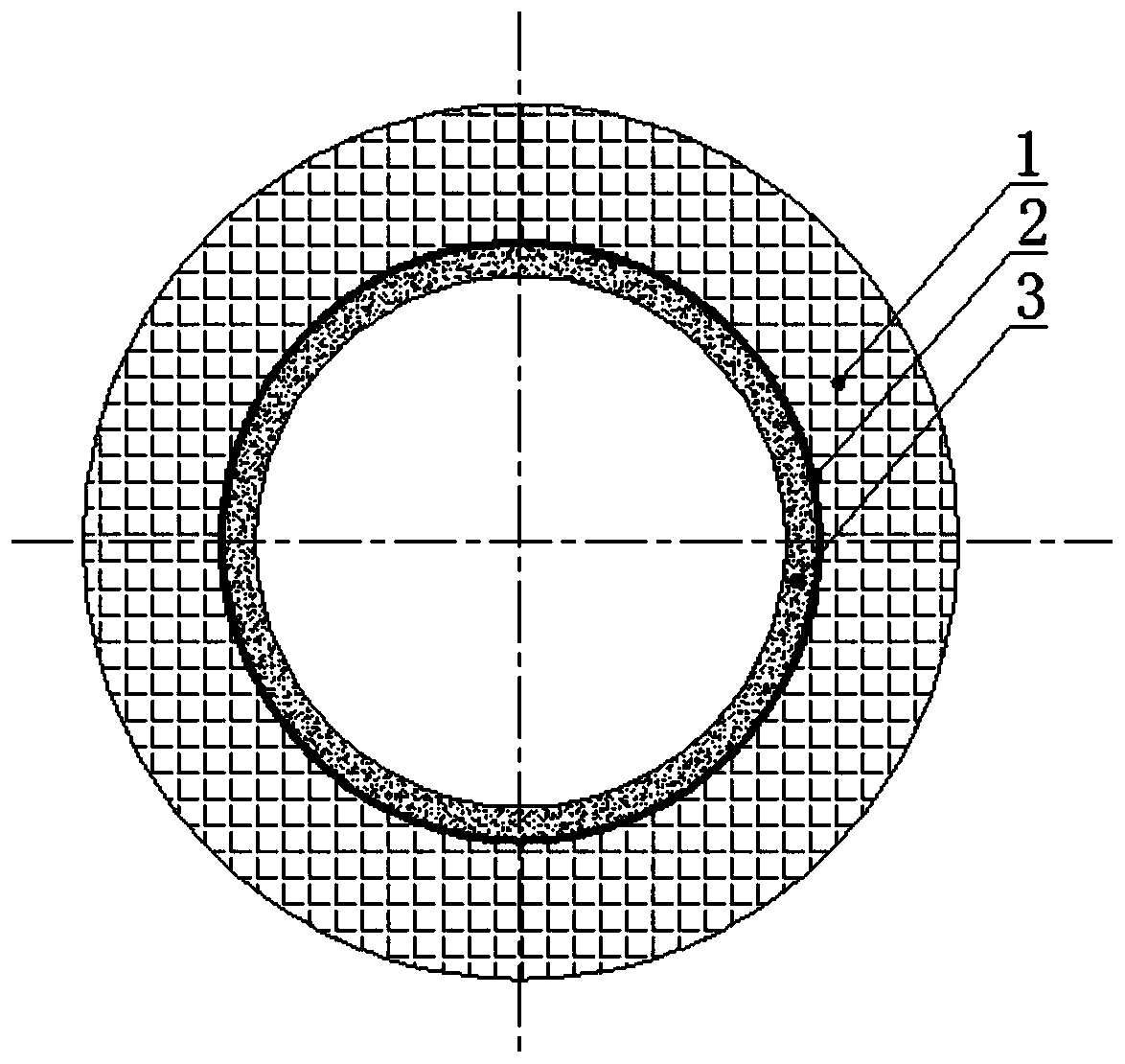

[0029] On the surface of refractory bricks in the transition zone of the rotary kiln (temperature 1400 ° C, length about 20 meters), use 25 mm thick zirconium-containing fiber heat insulation felt (maximum service temperature 1430 ° C), soaked with a mixed colloid of silica sol and aluminum sol ( The weight ratio is silica sol: aluminum sol = 30%: 70%, the concentration of the two glues is 30% solid content), and the high-temperature cement (high-temperature-resistant cement specially used for refractory bricks in the transition zone of the rotary kiln) is pasted on the firing process of the rotary kiln. The surface of the refractory brick with the belt is naturally dried, and the fiber felt forms a hard protective layer and adheres to the surface of the refractory lining. The density of the protective layer of zirconium-containing fiber heat insulation felt is 450Kg / m 3 , The thermal conductivity is 0.13W / mK (600°C).

[0030]On the surface of refractory bricks with a rotating...

Embodiment 2

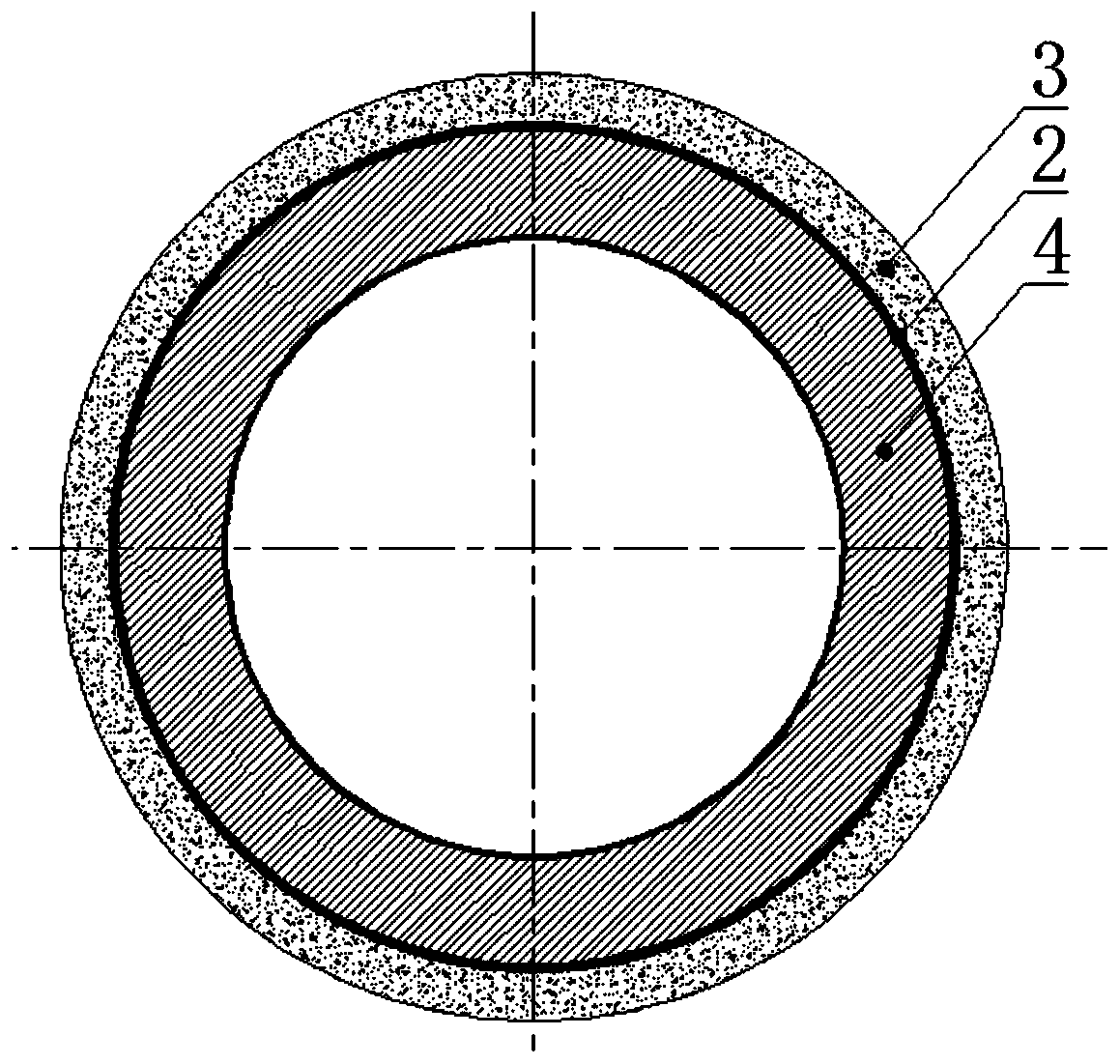

[0037] On the surface of the low-temperature refractory bricks of the rotary kiln (the temperature here is 1200-1250 ° C), the length is generally about 30 meters, and the ceramic fiber blanket soaked with high-temperature colloidal silica sol with a thickness of 25 mm (the maximum service temperature is 1260 ° C), with acid The high-temperature cement is pasted on the surface of the refractory brick in the low-temperature zone of the rotary kiln. After natural drying, the fiber blanket forms a hard protective layer and adheres to the surface of the refractory lining. The density of the protective layer is 350Kg / m 3 , The thermal conductivity is 0.12W / mK (600°C).

[0038] When the refractory lining of the previous rotary kiln was not protected by the heat insulation layer, 5-10 mm micro-cracks would appear on the surface of the refractory brick every time the temperature of the cold kiln was raised. Abrasion; when the kiln is stopped to measure the thickness of refractory bric...

Embodiment 3

[0041] For a cement rotary kiln with a daily output of 5,000 tons, after laying refractory bricks, the internal diameter is 4360mm. The paste construction of Example 1 and Example 2 requires the middle and lower half of the rotary kiln to be pasted, and the rotary kiln needs to be rotated 180 degrees before pasting. The other half of the refractory brick lining surface heat insulation protective layer, the construction speed is slow.

[0042] Using the spraying method, mix and spray the fiber and high-temperature bonding glue to the surface of the rotary kiln fired with kiln skin, the thickness is 25-30mm, and the density of the thermal insulation protection layer is 400-500Kg / m after drying 3 , The construction speed is increased by 2 times, the construction time is saved, the shell temperature is reduced by 50-70°C, the cracking degree of the refractory lining is protected, and the service life of the refractory lining is prolonged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com