Intermittent-type treatment system for high-concentration COD in industrial wastewater and treatment technology

A technology for treating system and industrial wastewater, applied in the direction of backflow water treatment, water/sewage treatment, water treatment parameter control, etc. It can solve the problems of no treatment system and process steps, high COD of wastewater, and achieve the effect of convenient and flexible treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

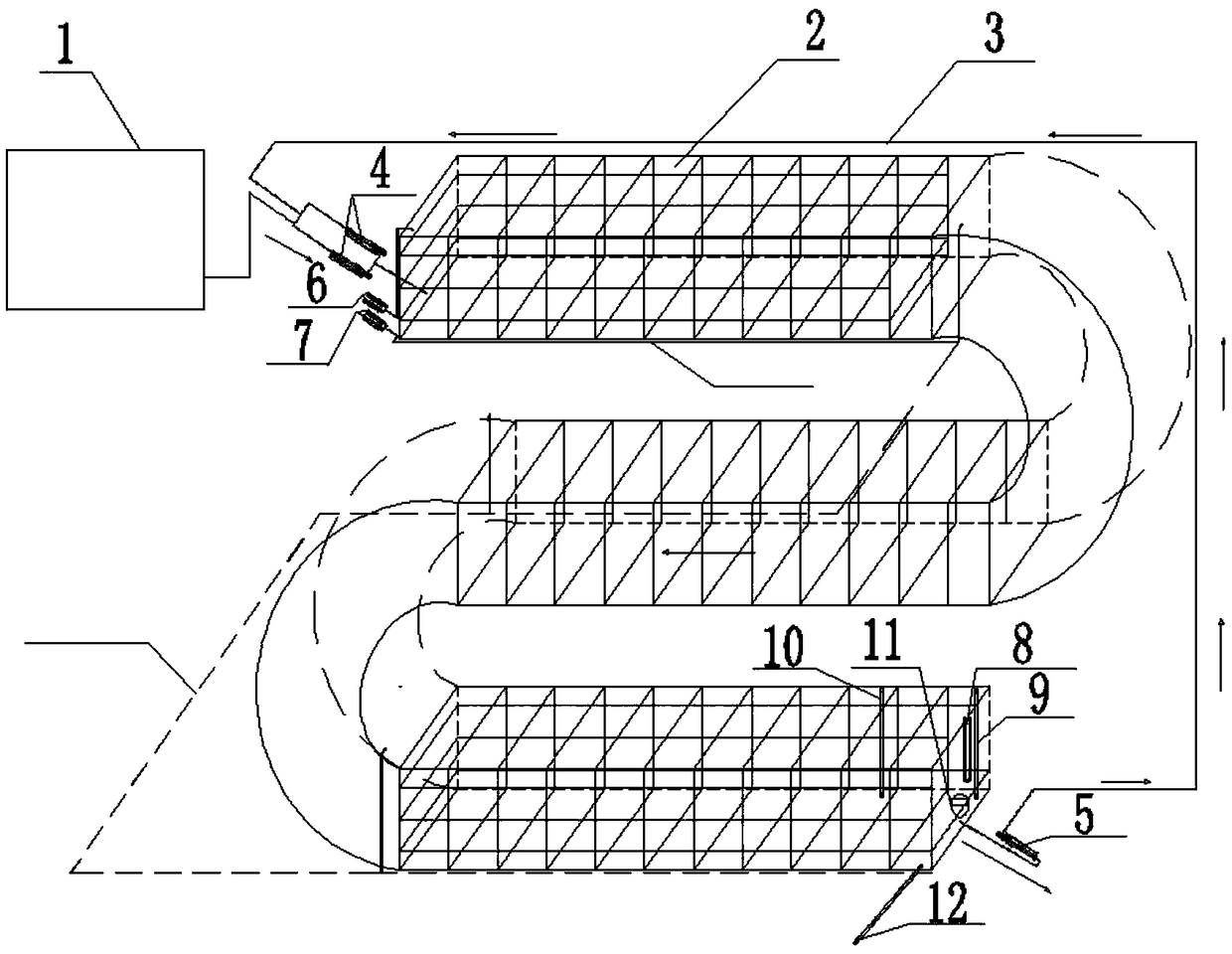

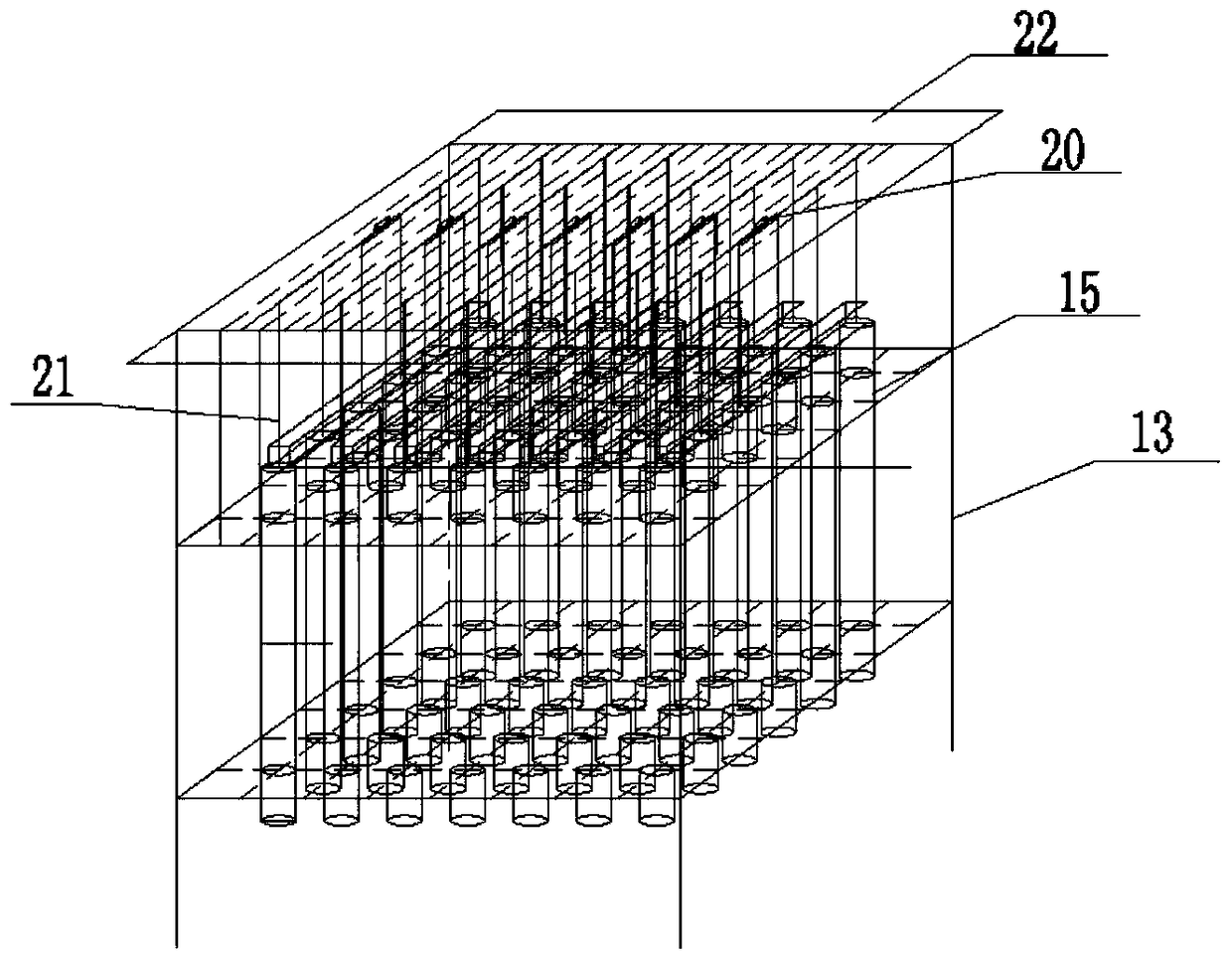

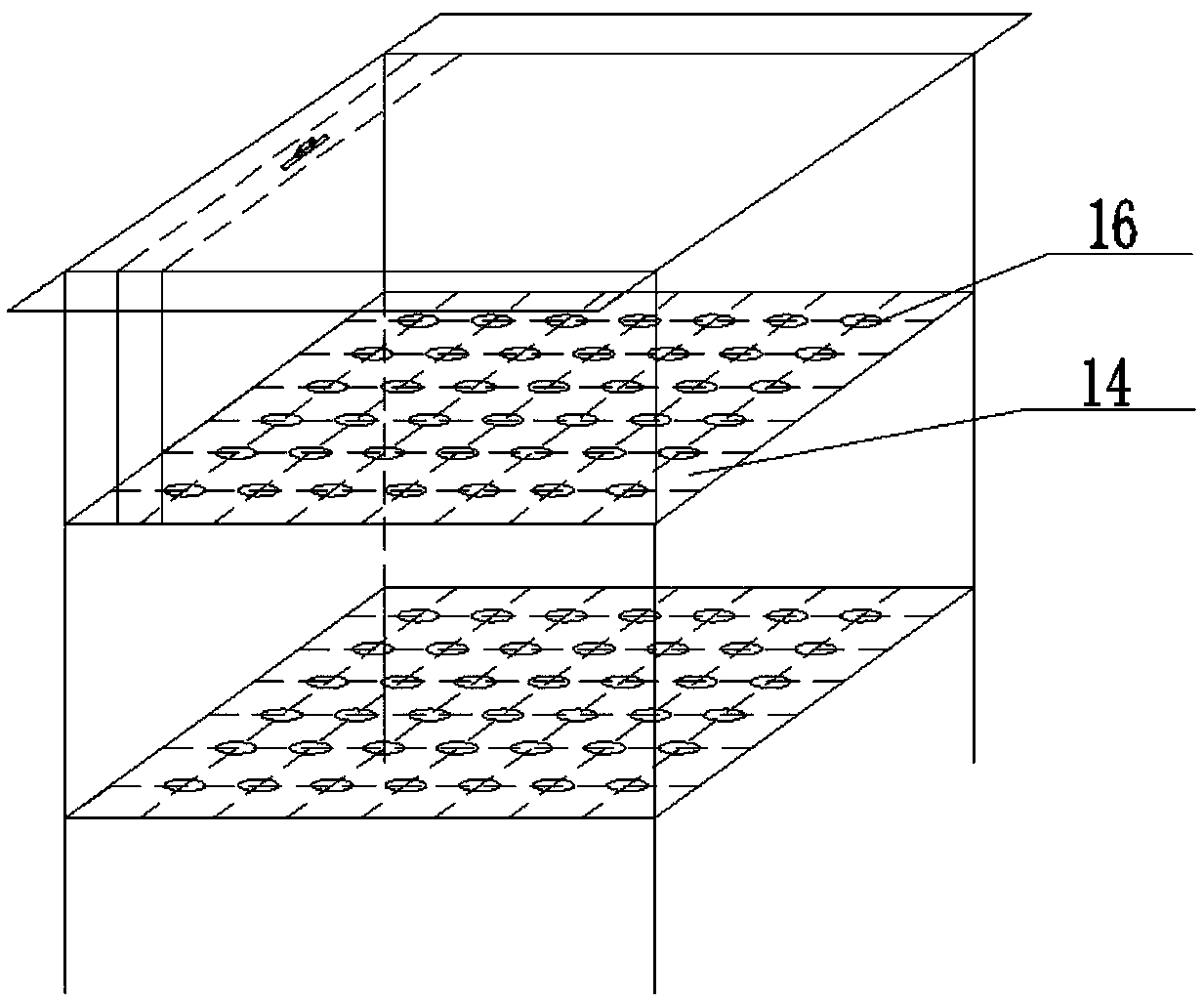

[0044] like figure 1 As shown, the present invention provides an intermittent treatment system for high-concentration COD in industrial wastewater, including a pretreatment device, a buffer device 1, a UV-Cu-Fenton advanced oxidation device 2, a dosing device, a wastewater conveying device, and a return pipeline 3 ; Wherein the pretreatment device is connected to the inlet of the buffer device 1, the waste water conveying device comprises a first waste water delivery pump 4 and a second waste water delivery pump 5, and the UV-Cu-Fenton advanced oxidation device 2 is at the entrance through the first waste water delivery pump 4 and the buffer. The outlet of the device 1 is connected, and the outlet is connected to the inlet through the second waste water delivery pump 5 through the return pipeline 3; the dosing device includes a front-end dosing pump 6 and a mid-way dosing pump 7, and the front-end dosing pump 6 is connected to the UV through the dosing pipeline. -The inlet of ...

Embodiment 1

[0063] All the sewage collected in this example comes from Yongning County Industrial Park, in which industrial wastewater accounts for more than 60%, and the rest is domestic sewage. After the wastewater is treated in the UV-Cu-Fenton advanced oxidation device 2, it reaches the first-level A (COD content less than 50mg / L) discharge standard.

[0064] The specific treatment process is as follows:

[0065] Step 1: The pretreated industrial wastewater is transported to the buffer device 1, the COD content in the wastewater is detected by the first water quality online detector, and the copper oxide (CuO) and hydrogen peroxide (CuO) and hydrogen peroxide ( H 2 O 2 ), the calculated amount of hydrogen peroxide required for the treatment of 1t of waste water is 1%, H 2 O 2 with Cu 2+ The molar ratio is 30:1.

[0066] Step 2: The waste water in the buffer device 1 is transported to the inlet of the UV-Cu-Fenton advanced oxidation device 2 through the first waste water delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com