A method for preparing micro-nano explosives using ultrasonic technology in liquid nitrogen

An ultrasonic technology, micro-nano technology, applied in explosives, explosives processing equipment, offensive equipment and other directions, to achieve the effect of not causing environmental pollution, avoiding the use of solvents, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

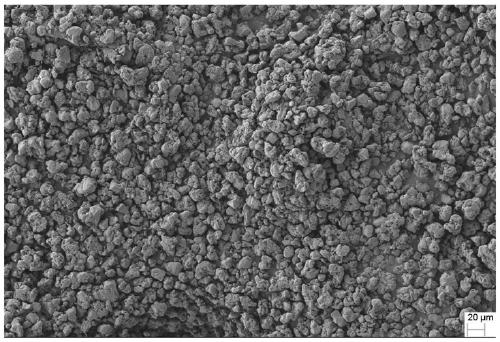

[0026] First, TATB was preheated at high temperature in a vacuum oven for 4 hours, and the preheating temperature was 60°C. Then, at room temperature, 1 g of TATB was added into the reaction bottle, and then about 50 ml of liquid nitrogen was poured into it, and the ultrasonic horn of the ultrasonic pulverizer was immersed under the liquid nitrogen liquid surface. Adjust the power of the ultrasonic pulverizer to 1000W, the working frequency to 40KHz, the pulse: on: 10s; off: 0.5s, the amplitude: Amp, 40%, the time of ultrasonic wave in liquid nitrogen is 10min, stop the ultrasonic wave, and then wait for the liquid nitrogen to volatilize, Obtain micronized TATB explosive crystals, figure 1 For this example, TATB crystal particles were prepared by ultrasonic technology in liquid nitrogen. It can be seen from the figure that the average particle size of TATB crystal particles is 16 μm.

Embodiment 2

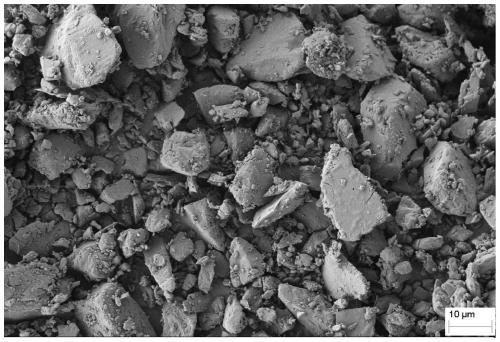

[0028] At room temperature, add 1g of HMX into the reaction bottle, then pour about 50ml of liquid nitrogen, and immerse the ultrasonic horn of the ultrasonic pulverizer under the liquid nitrogen liquid surface. Adjust the power of the ultrasonic pulverizer to 1000W, the working frequency to 30KHz, the pulse: on: 10s; off: 1s, the amplitude: Amp, 35%, the ultrasonic wave action time in liquid nitrogen is 8min, stop the ultrasonic wave, and then wait for the liquid nitrogen to volatilize, and get Micronized HMX explosive crystals. figure 2 For this example, HMX crystal particles were prepared by ultrasonic technology in liquid nitrogen. It can be seen from the figure that the average particle size of HMX crystal particles is 10 μm.

Embodiment 3

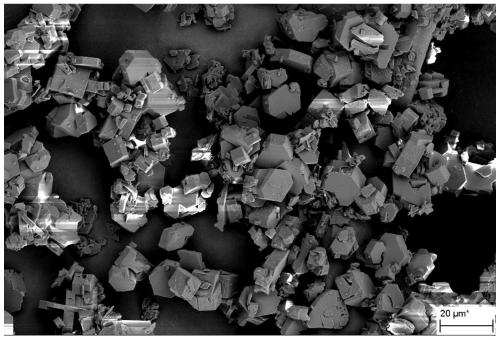

[0030] Firstly, DAAF was preheated at high temperature in a vacuum oven for 3.5 hours, and the preheating temperature was 55°C. At room temperature, add 1gDAAF into the reaction bottle, then pour about 50ml of liquid nitrogen, and immerse the ultrasonic horn of the ultrasonic pulverizer under the liquid nitrogen liquid surface. Adjust the power of the ultrasonic pulverizer to 1000W, the working frequency to 40KHz, the pulse: on: 10s; off: 1s, the amplitude: Amp, 20%, the ultrasonic wave action time in liquid nitrogen is 10min, stop the ultrasonic wave, and then wait for the liquid nitrogen to volatilize, and get Micronized DAAF explosive crystals. image 3 For this example, DAAF crystal particles were prepared by ultrasonic technology in liquid nitrogen. It can be seen from the figure that the average particle size of DAAF crystal particles is 9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com