Process for preparing polysiloxanel alkyl poly(methyl) acrylate as damping material

A technology of alkyl methacrylate and alkyl acrylate, which is applied in the field of polymer synthesis and its forming and processing, can solve the problem of high refractive index, no mention of vibration reduction and noise reduction of materials, and no report of material damping performance test data. and other problems, to achieve the effect of simplifying the process, significant economic and social benefits, and high damping value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The present invention is specifically described below through the examples, it is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, those skilled in the art can according to above-mentioned this SUMMARY OF THE INVENTION Some non-essential improvements and adjustments are made to the present invention.

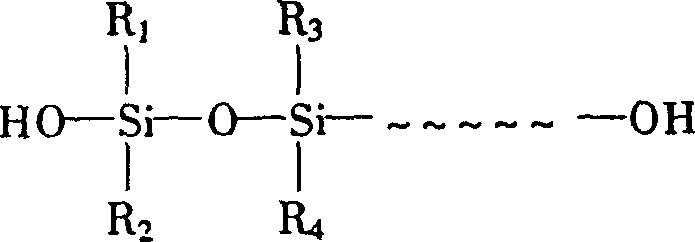

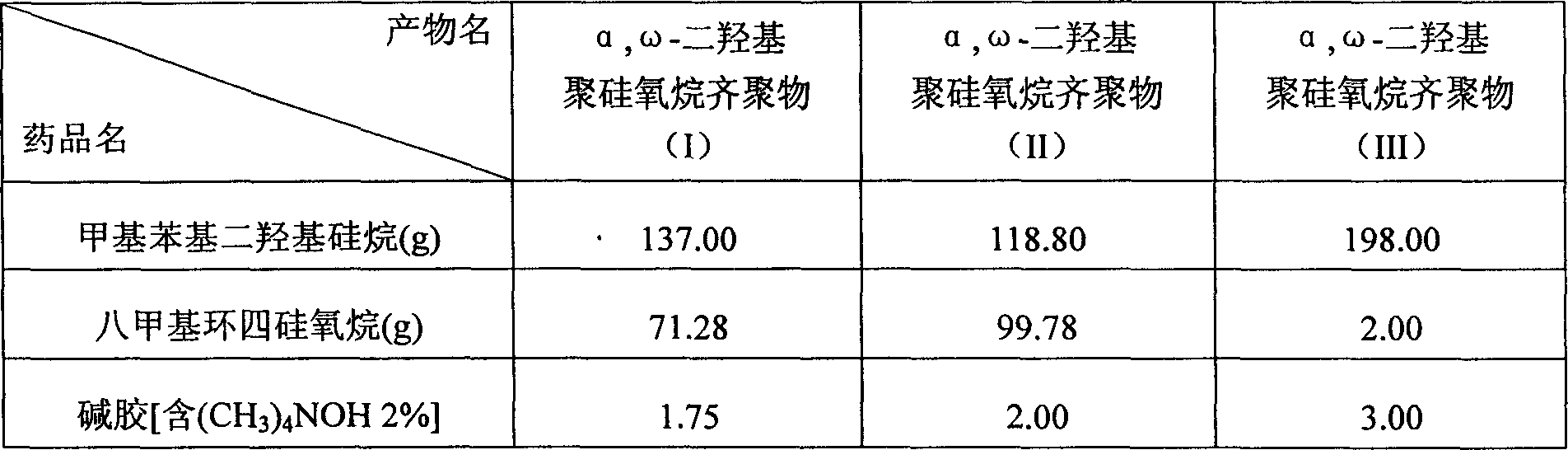

[0027] 1 to 3, for the preparation of α, ω-dihydroxymethylsiloxane oligomer, the specific formula components (wherein the parts of raw materials are all parts by weight unless otherwise specified), see Table 1 for details Show.

[0028] According to the formulation components in Table 1, methylphenyldihydroxysilane, octamethylcyclotetrasiloxane and alkali gum [containing (CH 3 ) 4 NOH 2%] into the reaction kettle with agitator, thermometer, condenser and gas inlet and outlet, start stirring, heat up to 110-120°C, when the vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| damping ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com