Automation assembly line device for updated version hot-dip galvanizing

An assembly line and equipment technology, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of complex structure and process, dirty working environment, low work efficiency of workers, etc. Liquid material loss, improve galvanizing efficiency, optimize the effect of assembly line process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

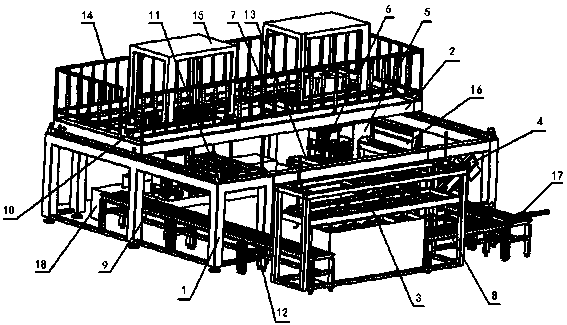

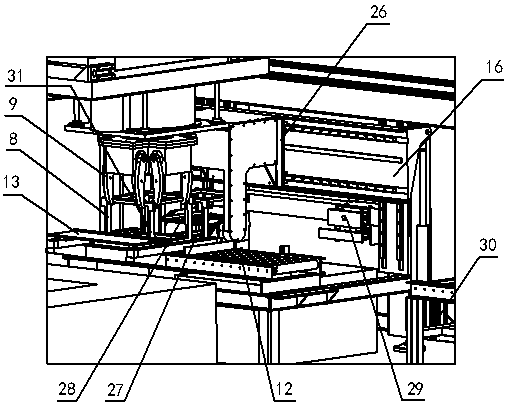

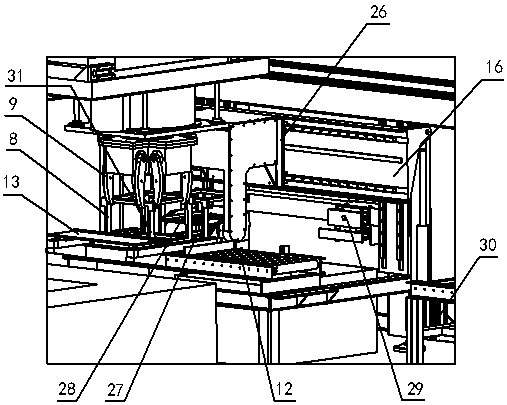

[0016] In order to overcome the defects existing in the existing hot-dip galvanizing device and meet the actual needs, an upgraded hot-dip galvanizing automatic assembly line equipment (such as Figure 1 to Figure 5 ), including an equipment frame 1, a raceway 12 that facilitates the movement of the workpiece frame 8, and a workpiece cleaning device 3, a workpiece galvanizing device, a cooling device and a finished product discharge device 4 arranged on the raceway 12, and the workpiece cleaning device 3 includes a lift servo The motor and the cleaning water tank and the plating solution tank located below the lifting servo motor, the raceway 12 are provided with a number of workpiece frame induction devices, and the workpiece galvanizing device includes a manipulator frame 2 and a second manipulator base 7 arranged on the manipulator frame 2 and First manipulator base 10, the second manipulator 6 is equipped with below the second manipulator base 7, the first manipulator 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com