High-breathability non-woven fabric for medical protective clothing

A gas-permeable, non-woven fabric technology, applied in protective clothing, clothing, clothing, etc., can solve the problems of difficult to meet market demand, low air permeability of medical protective clothing, etc., to achieve optimized porosity and water vapor permeability, excellent Compatibility, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

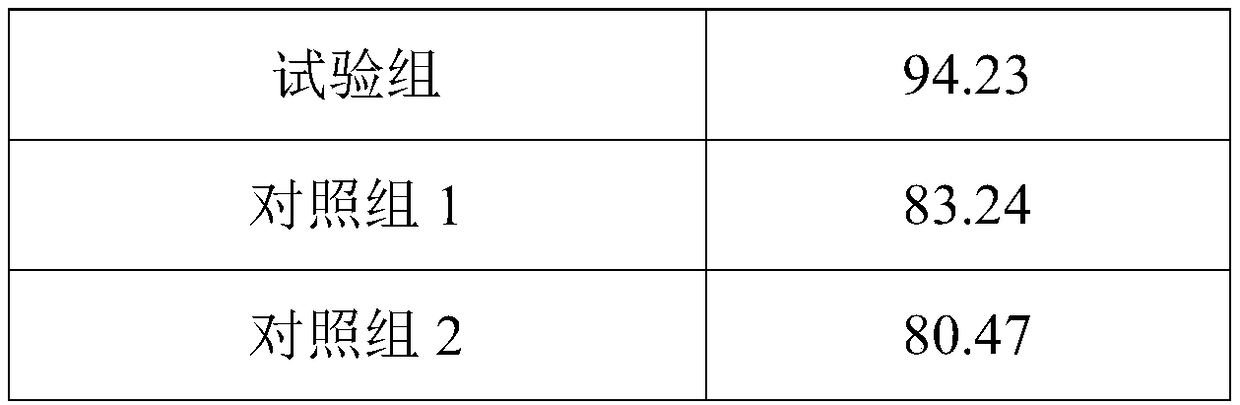

Examples

Embodiment 1

[0016] A highly air-permeable nonwoven fabric for medical protective clothing, the raw materials of which include by weight: 40 parts of acrylic fiber, 34 parts of polyacrylonitrile fiber, 8.5 parts of cellulose ester fiber, 27 parts of elastic fiber, and 4 parts of viscose fiber , 12 parts of additives, 1 part of chrysotile.

Embodiment 2

[0018] A highly air-permeable nonwoven fabric for medical protective clothing, the raw materials of which include by weight: 55 parts of acrylic fiber, 22 parts of polyacrylonitrile fiber, 13 parts of cellulose ester fiber, 18 parts of elastic fiber, and 8 parts of viscose fiber , 6 parts of additives, 3 parts of chrysotile;

[0019] Wherein, the additive is prepared according to the following process: the nano-calcium carbonate is placed in a high-speed mixing device with an atomizing injection device and a heating device, the temperature is raised, and the sericin aqueous solution is uniformly sprayed on the surface of the nano-calcium carbonate to obtain the additive.

Embodiment 3

[0021] A highly air-permeable nonwoven fabric for medical protective clothing, the raw materials of which include by weight: 45 parts of acrylic fiber, 28 parts of polyacrylonitrile fiber, 10 parts of cellulose ester fiber, 22 parts of elastic fiber, and 6 parts of viscose fiber , 8 parts of additives, 2 parts of chrysotile;

[0022] Wherein, the additive is prepared according to the following process: the nano-calcium carbonate is placed in a high-speed mixing device with an atomizing spray device and a heating device, the temperature is raised, and the sericin aqueous solution is evenly sprayed onto the surface of the nano-calcium carbonate to obtain the additive;

[0023] Before preparing the additive, the nano-calcium carbonate is dried so that the mass fraction of its moisture is below 0.2%;

[0024] Said heating up is heating up to 95°C;

[0025] The weight ratio of the nano-calcium carbonate to the sericin aqueous solution is 1.5:4;

[0026] The mass fraction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com